Shape follow-up support deformation control method for selective laser melting forming of thin-walled part

A technology of laser selective melting and thin-walled parts, which is applied in the field of forming thin-walled parts to achieve the effect of improving the forming quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, a thin-walled grid structure with a thickness of 2 mm to 5 mm is used as an embodiment, and the specific realization process is as follows:

[0041] 1. Select a thin-walled grid with a thickness of 2mm~2.5mm for the external aid plate, a height of 240mm, a large curved flat plate, a grid cell structure in the middle area, and a large curved thin-walled plate in the outer edge structure. structure, the thickness is 2mm and the width is 30mm~60mm, such as figure 1 shown;

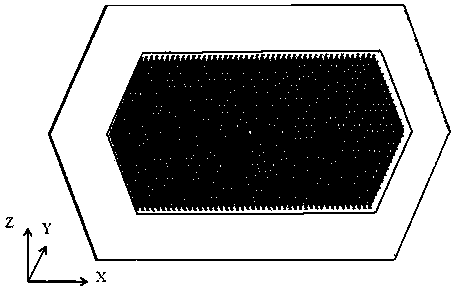

[0042] 2. Convert the 3D model of the thin-walled grid structure into the STL 3D process digital model in the format required for forming, such as figure 2 shown;

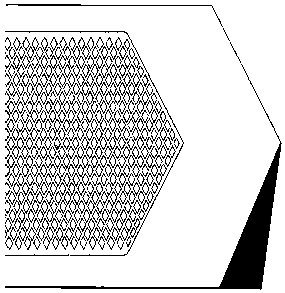

[0043] 3. Analyze the formability of the thin-walled grid structure, design its final forming plan, and determine the forming method of the thin-walled grid parts. The thin-walled grid structure is formed vertically, and the placement position is diagonally. The included angle between the angle and the X-axis direction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com