Method and device for improving forming quality of laser additive manufacturing thin-wall parts

A technology of forming quality and laser additive materials, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement. It can solve the problems of thermal stress accumulation cracking of cladding deposits, poor cladding and forming surface quality, and coarse microstructure. Achieve the effect of shortening the development and manufacturing cycle, improving surface quality, and overcoming molten pool flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

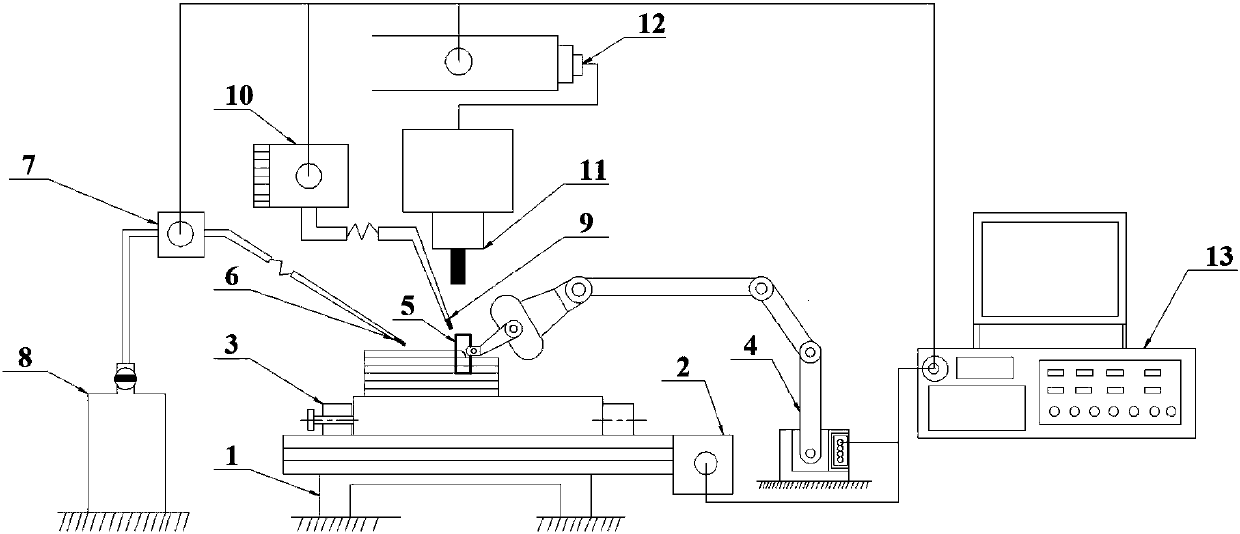

[0033] Such as figure 1 As shown, a device for improving the forming quality of thin-walled parts manufactured by laser additive manufacturing according to the present invention includes a mobile platform system, a laser metal deposition system, an auxiliary forming system, an active cooling system and a central control system.

[0034] The mobile platform system includes a fixed worktable 1, a three-axis mobile platform 2, a high-precision robotic arm 4 and a mechanical gripper 14, the mechanical gripper 14 is installed on the high-precision robotic arm 4, and the three-axis mobile platform 2 and high-precision robotic arm 4 Installed on the fixed workbench 1, the three-axis mobile platform 2 is equipped with a workpiece fixture 3, and the workpiece fixture 3 clamps and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com