Preparation molding method of Glare component

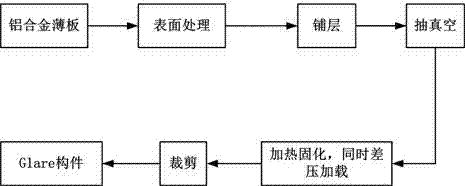

A component and aging forming technology, which is applied in the preparation and forming of Glare components and the preparation and forming of metal components, can solve the problems of limited improvement of the forming limit of Glare components, difficulty in springback control, poor forming accuracy, etc., and achieve low production costs. , the effect of high engineering application value and high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

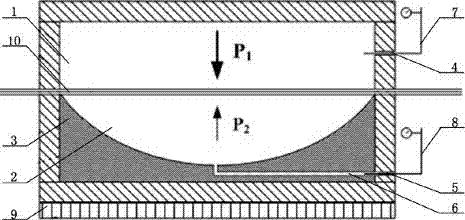

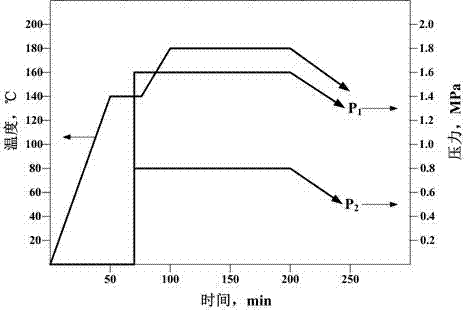

Method used

Image

Examples

Embodiment 1

[0032] The first step is to select a 2024-T3 aluminum alloy blank of 500mm×500mm×0.4mm, and perform phosphoric acid anodic oxidation treatment, so that the surface of the 2024-T3 aluminum alloy can obtain a more favorable surface morphology for hot-pressing resin composite;

[0033] The second step is to select and cut S4 high-strength glass fiber reinforced epoxy resin prepreg of 500mm×500mm×0.125mm, and its resin content is 30wt%;

[0034] The third step is to adopt a 3 / 2 orthogonal laminate structure design, and lay composite laminates in the following order: 2024-T3 aluminum alloy / 0°S4 high-strength glass fiber reinforced epoxy resin prepreg / 90°S4 high-strength glass fiber reinforced Epoxy resin prepreg / 2024-T3 aluminum alloy / 0°S4 high-strength glass fiber reinforced epoxy resin prepreg / 90°S4 high-strength glass fiber reinforced epoxy resin prepreg / 2024-T3 aluminum alloy, 2024 per layer - Lay 70g / m between T3 aluminum alloy and S4 high-strength glass fiber reinforced epoxy...

Embodiment 2

[0040] The first step is to select 1000mm×500mm×0.3mm 2060-W (quenched) aluminum-lithium alloy for surface sandblasting, so that the surface of 2060-W aluminum-lithium alloy aluminum alloy can obtain a more favorable surface shape for hot-pressing resin composite. appearance;

[0041] The second step is to select and cut 1000 mm×500 mm×0.125mm S4 high-strength glass fiber reinforced medium temperature epoxy resin prepreg with a resin content of 40wt%;

[0042] The third step is to adopt a 2 / 1 unidirectional laminate structure design, and lay composite laminates in the following order: 2060-W aluminum-lithium alloy / 0°S4 high-strength glass fiber reinforced medium-temperature epoxy resin prepreg / 0°S4 high-strength Glass fiber reinforced medium temperature epoxy resin prepreg / 2060-W aluminum-lithium alloy, each layer of 2060-W aluminum lithium alloy and S4 high-strength glass fiber reinforced medium temperature epoxy resin prepreg is laid at 180g / m 2 epoxy resin film;

[0043] ...

Embodiment 3

[0048] The first step is to select 500mm×500mm×0.35mm 7075-T4 aluminum alloy for surface sandblasting treatment, so that the surface of 7075-T4 aluminum alloy can obtain a more favorable surface morphology for hot-pressing resin composite;

[0049] The second step is to select and cut 500 mm×500 mm×0.125mm S4 high-strength glass fiber reinforced medium temperature epoxy resin prepreg with a resin content of 40wt%;

[0050] The third step is to adopt a 4 / 3 orthogonal laminate structure design, and lay composite laminates in the following order: 7075-T4 aluminum alloy / 0°S4 high-strength glass fiber reinforced medium-temperature epoxy resin prepreg / 90°S4 high-strength glass Fiber reinforced medium temperature epoxy resin prepreg / 7075-T4 aluminum alloy / 0°S4 high strength glass fiber reinforced medium temperature epoxy resin prepreg / 90°S4 high strength glass fiber reinforced medium temperature epoxy resin prepreg / 7075-T4 aluminum Alloy / 0°S4 high-strength glass fiber reinforced medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com