Shell, and preparation method thereof, and electronic equipment

A shell and substrate technology, applied in the field of shell and its preparation, can solve the problems of poor drop resistance of mobile phones, lack of impact resistance, and the need for further research on shells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

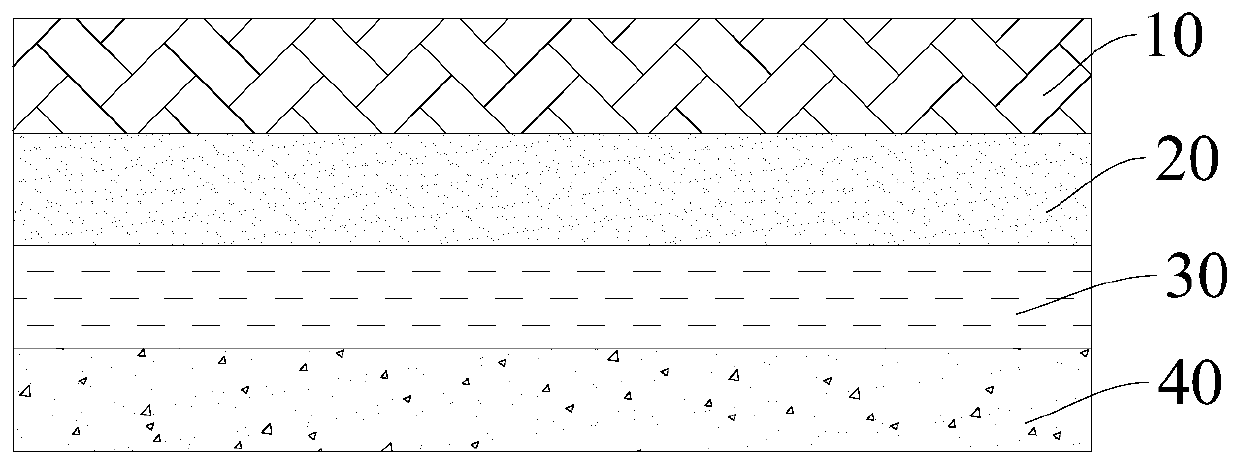

[0067] The structure of the shell is as figure 2 shown, yes figure 2 The falling ball impact test is performed on the shell in order to verify the drop resistance of the shell. The test method is: use steel balls of different weights and impact the shell at different distances. The test results are shown in Table 1.

[0068] Table 1

[0069]

[0070] In Table 1, A / B means that the falling ball impact test is performed on B number of shells, and cracking occurs in the UV texture layer and / or the base color ink layer in A (A≤B) number of shells.

Embodiment 2

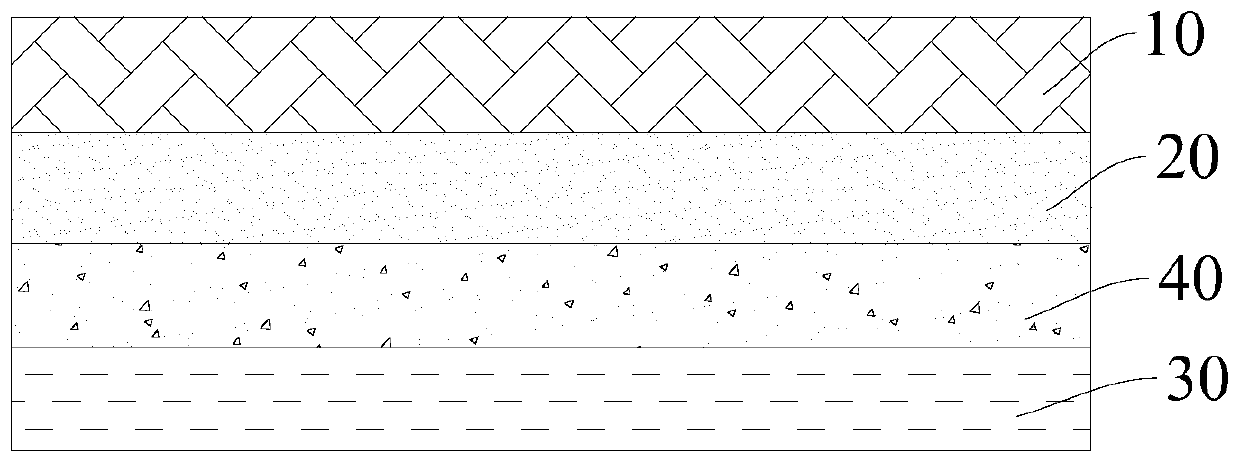

[0072] The structure of the shell is as Figure 7 shown, yes Figure 7 The falling ball impact test was carried out on the shell in order to verify the drop resistance performance of the shell. The test method is the same as that in Example 1, and the test results are shown in Table 2.

[0073] Table 2

[0074]

Embodiment 3

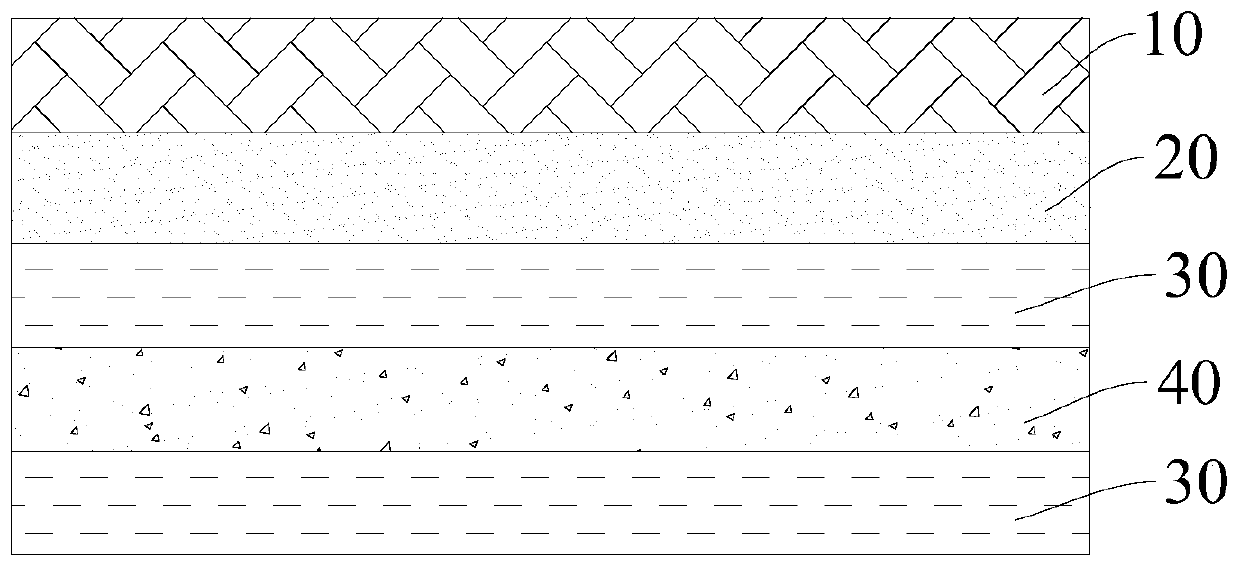

[0076] Shell structure such as Figure 10 shown, yes Figure 10 The falling ball impact test was carried out on the shell in order to verify the drop resistance performance of the shell. The test method is the same as that in Example 1, and the test results are shown in Table 3.

[0077] table 3

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com