Mg-Al-Si spinelle crystallized glass

A technology of glass-ceramics and spinel, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high performance requirements of zirconia powder, insufficient strength and hardness, and low yield rate of products. Achieve the effect of light weight, low cost and superior dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

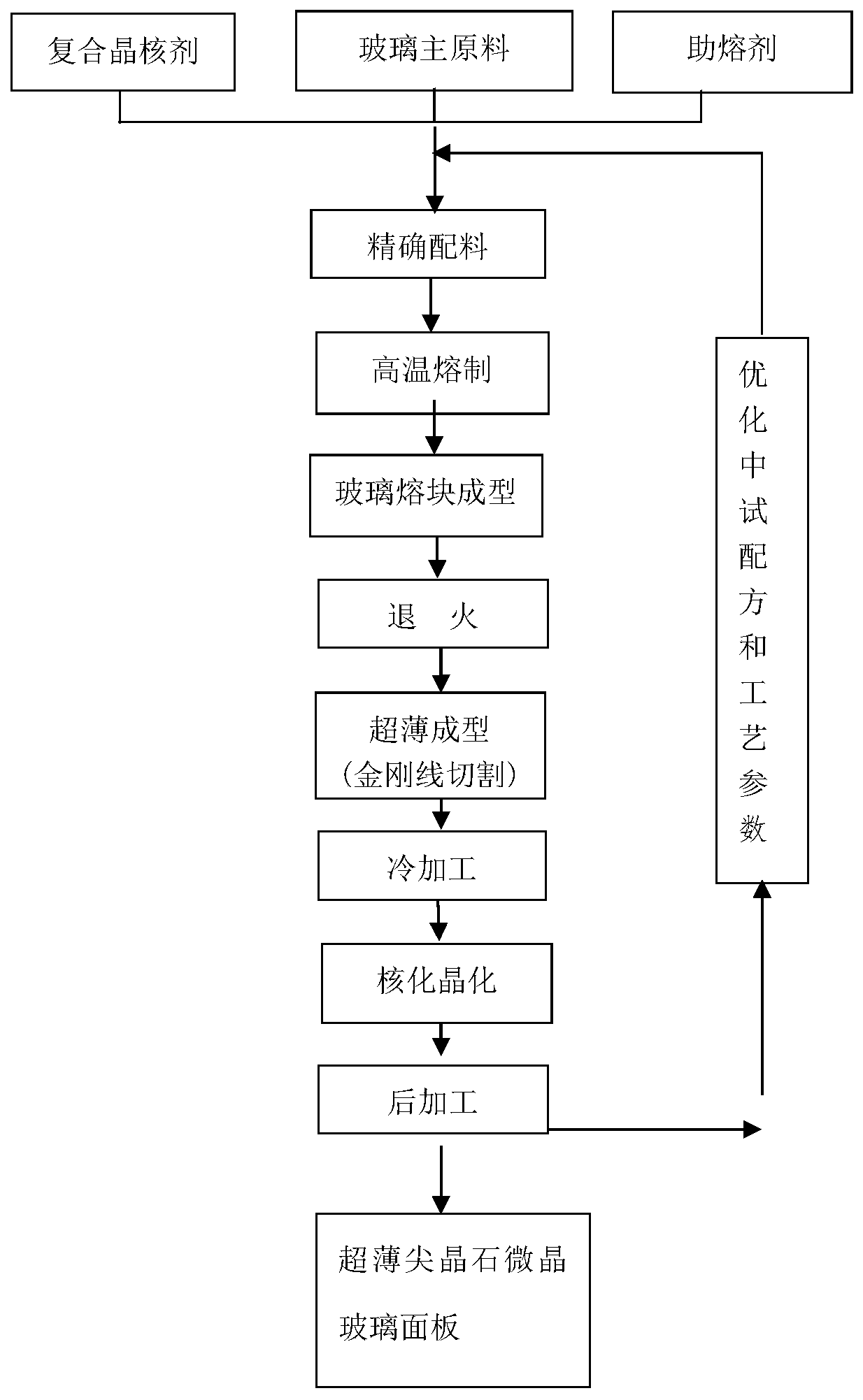

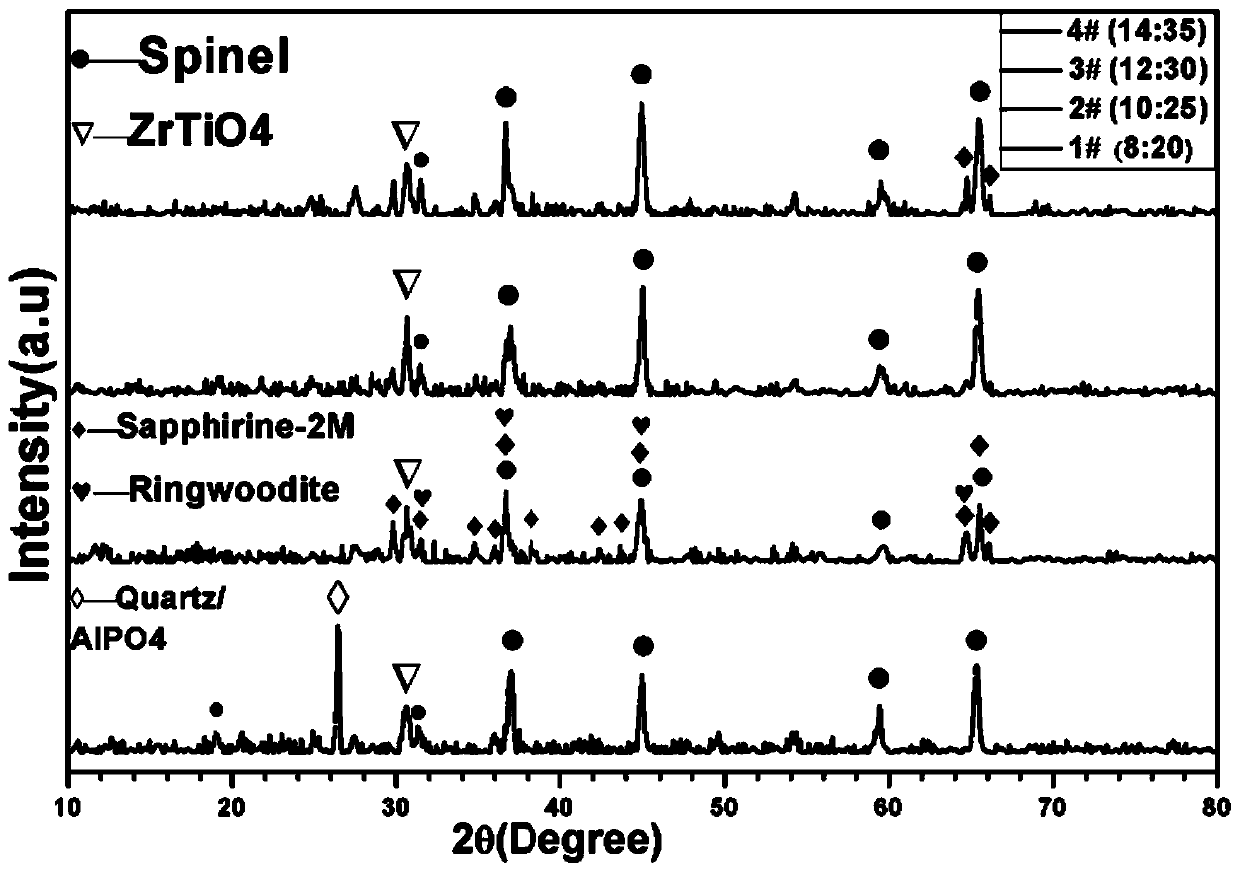

[0033] Attached below Figure 1-3 The present invention is further illustrated by the various examples in the table of examples and examples.

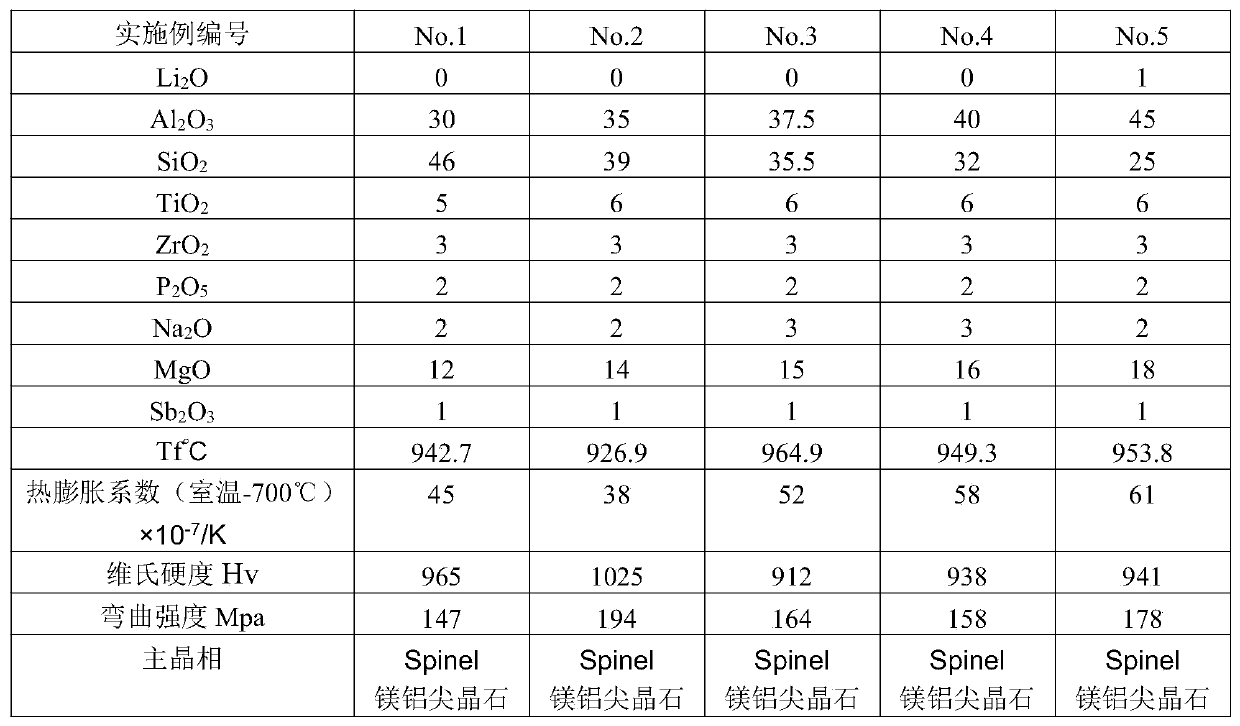

[0034]A magnesium-aluminum-silicon spinel glass-ceramic, which uses magnesium-aluminum spinel as the main crystal phase, and can be mainly used for ultra-thin white spinel glass-ceramics for smart 5G mobile phone back covers. Its basic components are composed of SiO2, Al2O3, MgO, TiO2, ZrO2, P2O5, Li2O and Na2O or K2O, plus clarifier Sb2O3. The composition of the glass-ceramics of the present invention is by weight percent: Al2O3 20-45wt%, SiO225-60wt%, MgO8-18wt%, TiO23-10wt%, ZrO20-5wt%, P2O50-3wt%, Li2O 0-2wt%, Na2O0~2wt%, K2O0~2wt%, Sb2O30.5-3wt%.

[0035] SiO2, Al2O3, and MgO have certain composition ranges in the glass-ceramic with magnesium-aluminum spinel as the main crystal phase. According to its three-phase diagram and comprehensive analysis of its melting and main crystal phase, the content of SiO2 is limited to 25-60wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com