Process for spraying plastic parts of mobile phone and mobile phone shell made by adopting process

A technology for mobile phone shells and plastic parts, which is applied to the surface coating liquid device, coating, telephone structure, etc., which can solve the problems of reducing the adhesion between coatings, large consumption of pigments, and increasing production costs. Achieve the effects of being convenient for large-scale promotion and application, low cost and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

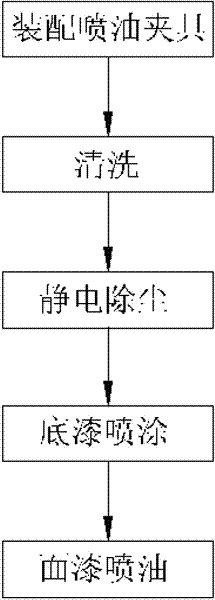

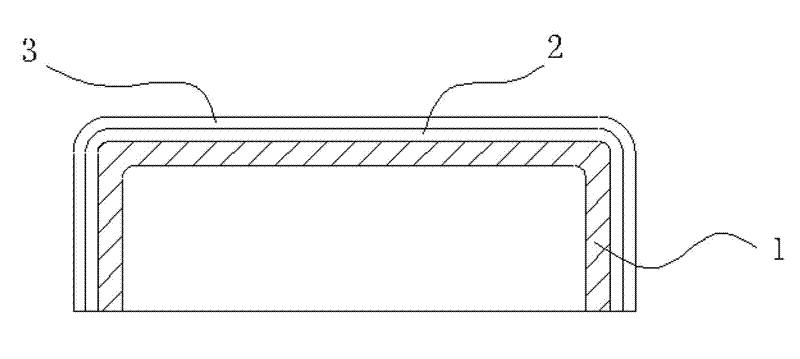

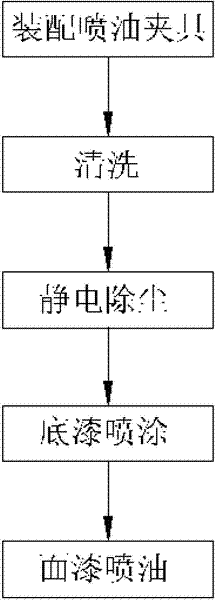

[0052] Example: see figure 1 and figure 2 , the present embodiment provides a mobile phone plastic parts spraying process, which includes the following steps:

[0053] (1) Assemble the fuel injection fixture: Prepare the fuel injection fixture to clamp the plastic part 1 of the mobile phone on the spraying line; fix the plastic part 1 of the mobile phone on the fuel injection fixture, and then fix the fuel injection fixture on the rotation system in a centralized manner On the tool, the motor drives the self-rotating tool to rotate at high speed to ensure that the paint liquid is quantitatively, uniformly and continuously delivered to the surface of the plastic part 1 of the mobile phone by means of air spraying through the fixed spray gun. Form a uniform and continuous paint film;

[0054] (2) Cleaning: Clean the plastic part 1 of the mobile phone on the oil injection fixture to remove moisture, stains and foreign matter adsorbed on the surface of the plastic part 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com