Mobile terminal casing and manufacturing method thereof

A technology of mobile terminals and manufacturing methods, which is applied in the direction of manufacturing tools, glass manufacturing equipment, portable casings, etc., and can solve problems such as complex processing, high manufacturing costs, and limited storage space inside product casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The mobile terminal housing of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

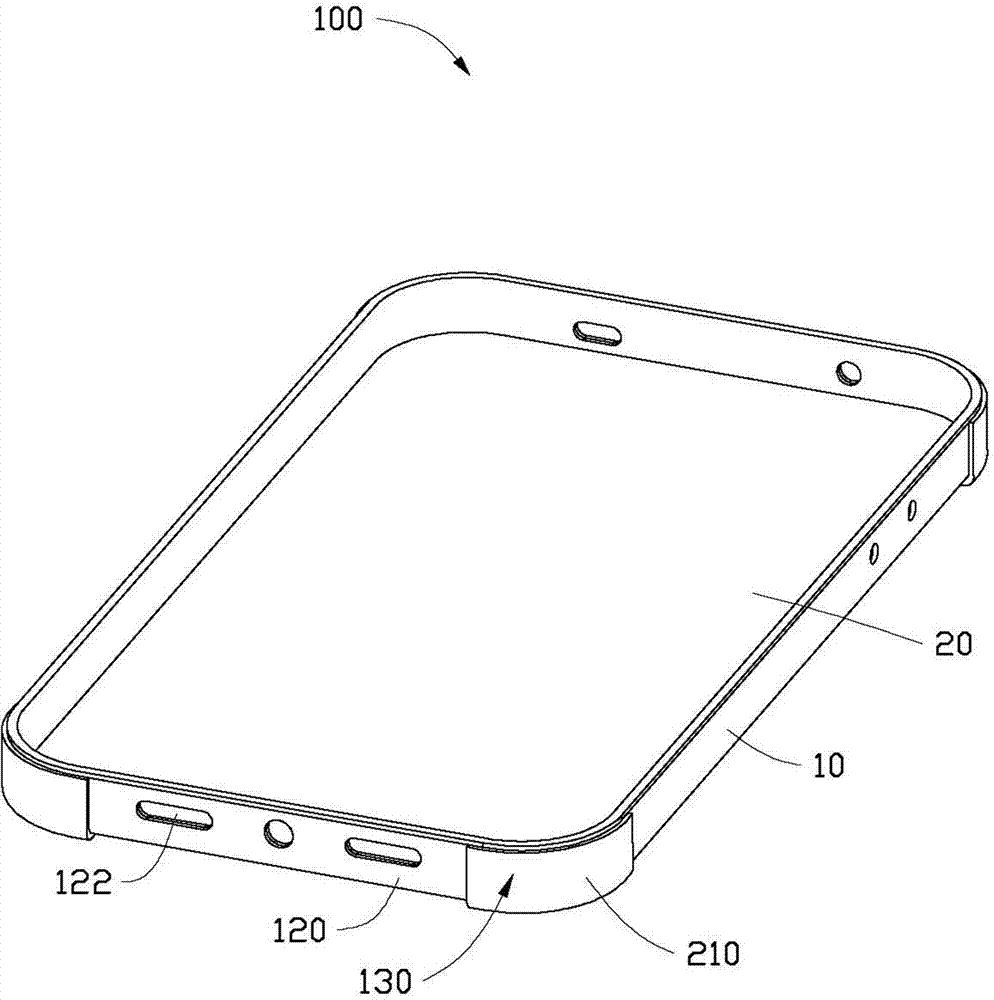

[0019] The mobile terminal casing 100 provided by the embodiment of the present invention can be used in various mobile terminals, such as mobile phones, tablet computers, notebooks and other electronic devices. like figure 1 As shown, the mobile terminal housing 100 is roughly in the shape of a rectangular box, including a glass housing part 10 and a plastic housing part 20 attached to the glass housing part 10 .

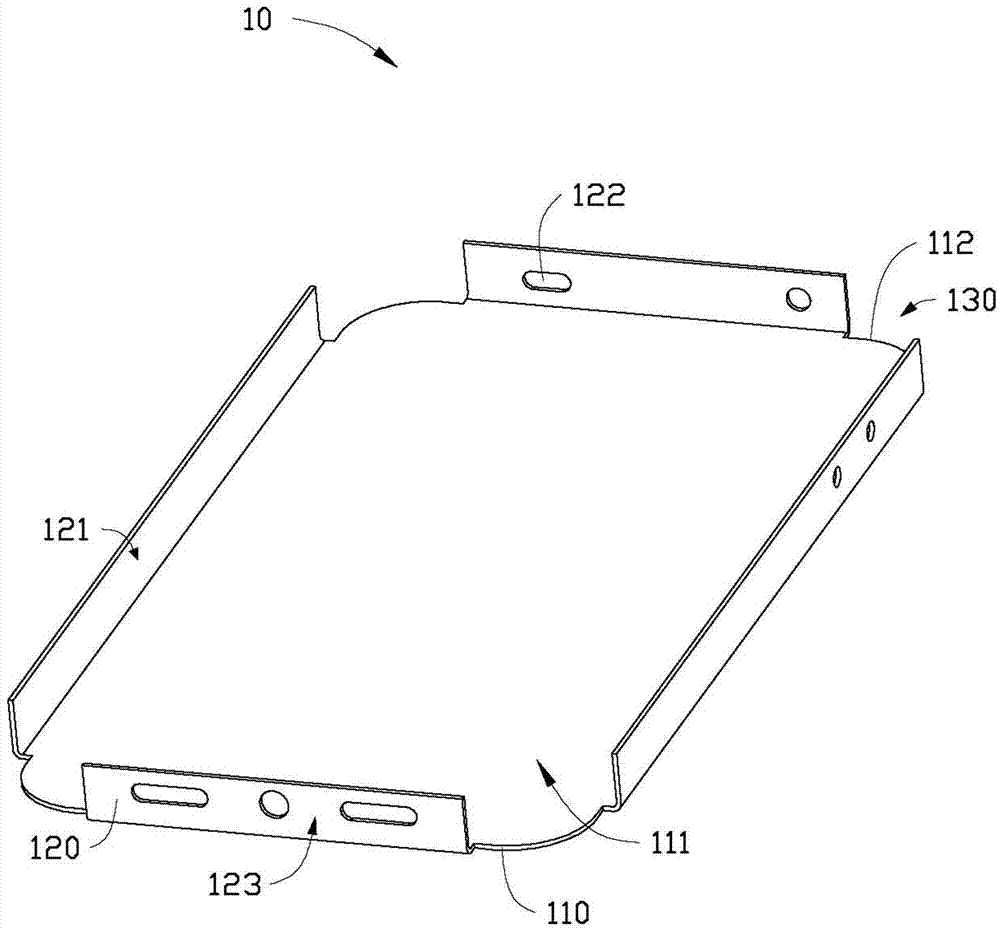

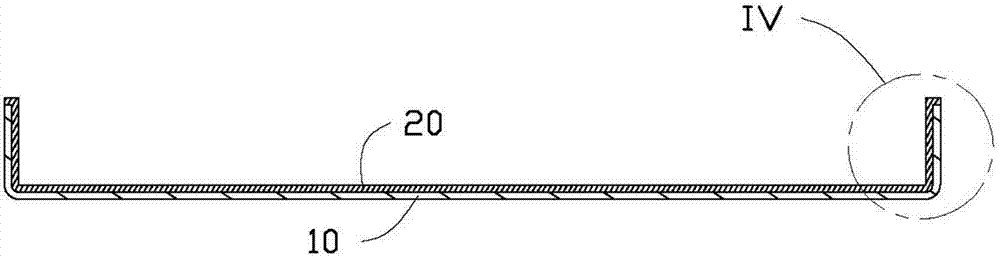

[0020] Please also refer to figure 2 The glass housing part 10 includes a bottom shell 110 , a plurality of side walls 120 vertically connected to the bottom shell 110 , and a plurality of gaps 130 between adjacent side walls 120 . A plurality of sidewalls 120 vertically extend along the edge of the bottom case 110 to the same side. The surface of the bottom shell 110 opposite to the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com