Low-temperature impact-resistant and low stress whitening-resistant long glass fiber reinforced polypropylene material, and preparation method and application thereof

A polypropylene material, low stress technology, applied in the field of reinforced modified polypropylene materials, can solve the problems of filling materials not meeting the requirements, affecting the appearance of parts, and only focusing on materials, so as to improve the drop strength and stress whitening resistance , good drop resistance, and the effect of reducing stress whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

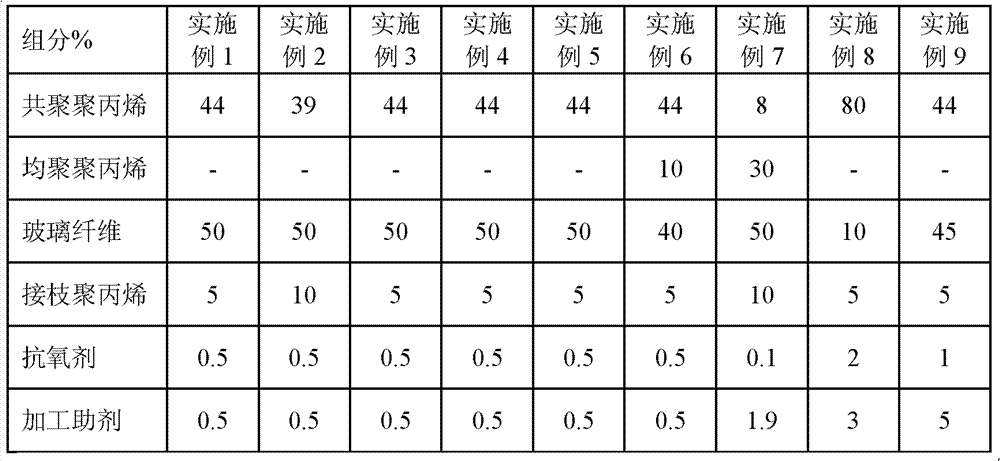

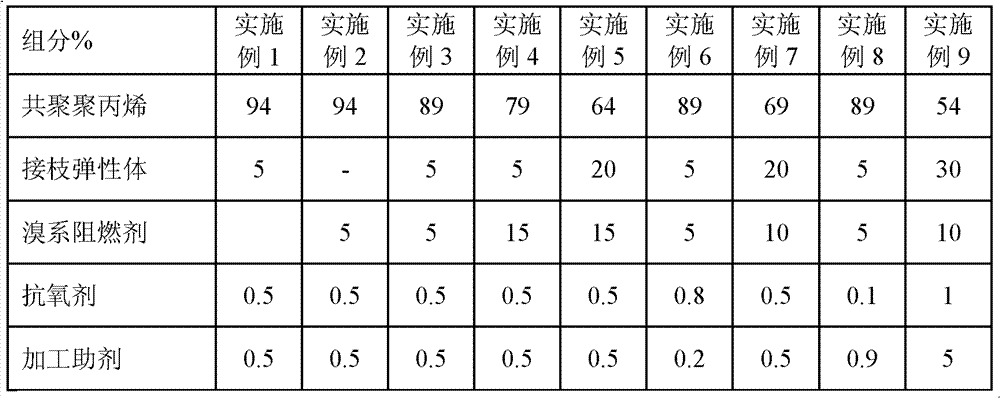

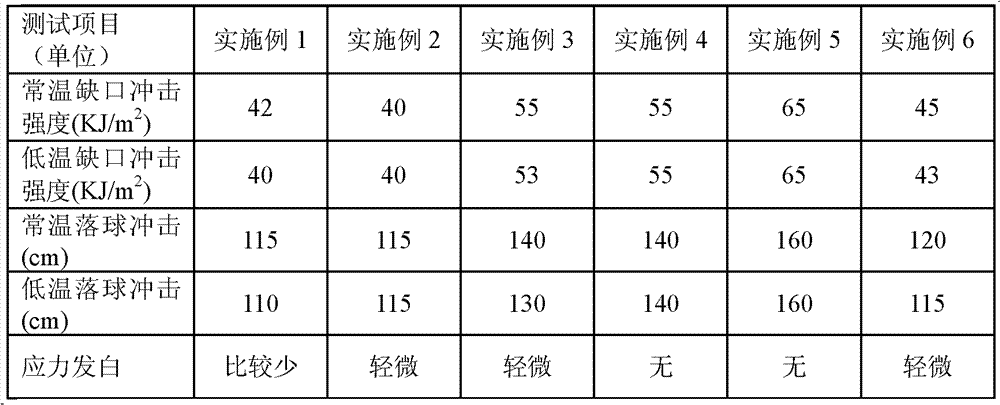

Embodiment 1

[0039] The low-temperature impact-resistant, low-stress whitening long glass fiber reinforced polypropylene material described in this embodiment, its components are 60% of long glass fiber reinforced polypropylene masterbatch by weight percentage, high low temperature impact resistance, low stress whitening masterbatch Grain 40%, wherein the components in the long glass fiber reinforced polypropylene masterbatch are composed of the following components, and the specific proportions are shown in Table 1 by weight percentage: copolymerized polypropylene, glass fiber, maleic acid grafted polypropylene, Antioxidant, processing aid stearic acid; low temperature impact resistance, low stress whitening masterbatch components are composed of the following components, the specific proportions are shown in Table 2 by weight percentage: copolymerized polypropylene, grafted elastomer POE, antioxidant, processing aid erucamide; length of long glass fiber reinforced polypropylene masterbatc...

Embodiment 2

[0045] The low-temperature impact-resistant, low-stress whitening long glass fiber reinforced polypropylene material described in this embodiment, its components are long glass fiber reinforced polypropylene masterbatch 60% by weight percentage, low-temperature impact resistance, low-stress whitening masterbatch 40% %, wherein the components in the long glass fiber reinforced polypropylene masterbatch are composed of the following components, and the specific proportions are shown in Table 1 by weight percentage: copolymerized polypropylene, glass fiber, acrylic grafted polypropylene, antioxidant, processing Auxiliary butyl stearate; Low-temperature impact-resistant, low-stress whitening masterbatch The components in the masterbatch are composed of the following components, and their specific proportions are shown in Table 2 by weight percentage: copolymerized polypropylene, grafted EPDM elastomer, bromine Epoxy resin, antioxidant, processing aid ethylene bis stearamide; long g...

Embodiment 3

[0048] The low-temperature impact-resistant, low-stress whitening long glass fiber reinforced polypropylene material described in this embodiment, its components are long glass fiber reinforced polypropylene masterbatch 60% by weight percentage, low-temperature impact resistance, low-stress whitening masterbatch 40% %, wherein the components in the long glass fiber reinforced polypropylene masterbatch are composed of the following components, and the specific proportions are shown in Table 1 by weight percentage: copolymerized polypropylene, glass fiber, acrylic grafted polypropylene, antioxidant, processing Auxiliary butyl stearate; Low-temperature impact-resistant, low-stress whitening masterbatch The components in the masterbatch are composed of the following components, and their specific proportions are shown in Table 2 by weight percentage: copolymerized polypropylene, grafted POE elastomer, bromine Polystyrene, antioxidant, processing aid ethylene bis stearamide; long gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com