Fiber-reinforced random copolymerized polypropylene composite pipe of β-crystal form and preparation method thereof

A random copolymerization and fiber-reinforced technology, which is applied in the direction of chemical instruments and methods, tubular articles, synthetic resin layered products, etc., can solve problems such as hidden quality problems and delamination, and achieve improved pressure resistance, good hygienic performance, and solution The effect of low temperature brittleness problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

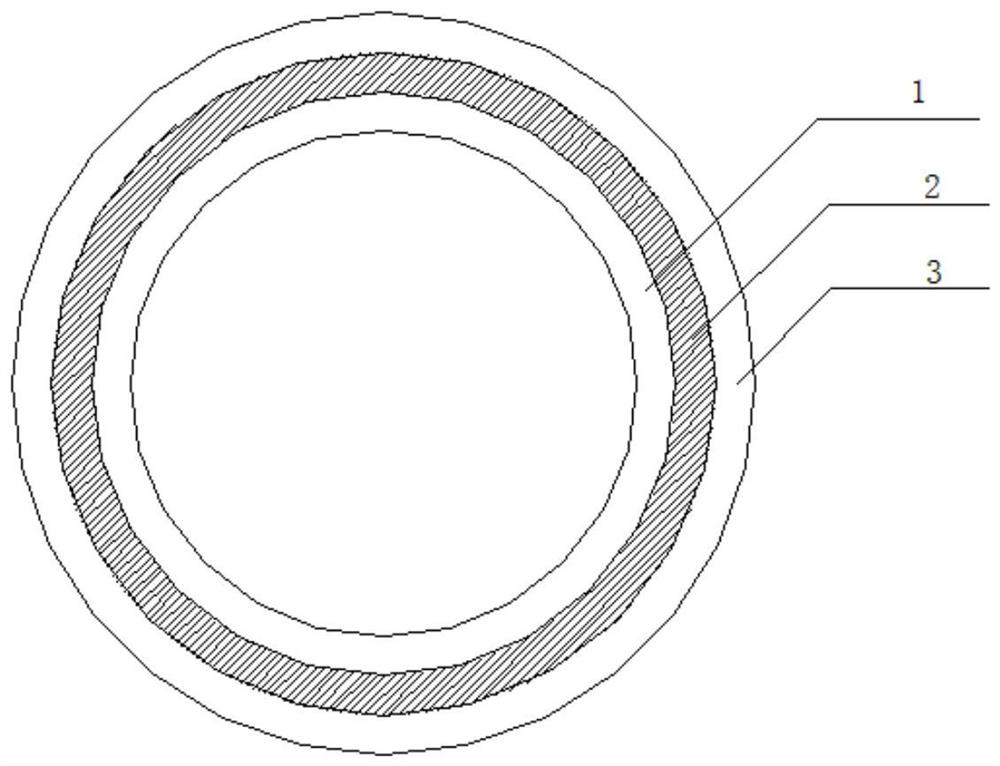

[0072] Please see attached figure 1 , a fiber-reinforced β-crystalline random copolymer polypropylene composite pipe is characterized in that it comprises an outer layer 3, an intermediate layer 2 and an inner layer 1, and an intermediate layer is arranged between the outer layer and the inner layer; the material of the outer layer It is β-crystal random copolymerized polypropylene, the material of the middle layer is β-crystal random copolymerized polypropylene reinforced by silica fiber, and the material of the inner layer is β-crystal random copolymerized polypropylene containing antibacterial masterbatch.

[0073] The material of the outer layer of the pipe is β-crystal random copolymerized polypropylene, which ensures the hot-melt connection of the plastic pipe.

[0074] The material of the middle layer of the pipe is β-crystal random copolymerized polypropylene particles reinforced by silica fiber, the mass fraction of silica fiber in the material of the middle layer is ...

Embodiment 2

[0136] A fiber-reinforced random copolymer polypropylene composite pipe of β crystal form is characterized in that it comprises an outer layer, an intermediate layer and an inner layer, and an intermediate layer is arranged between the outer layer and the inner layer; the material of the outer layer is β crystal form The material of the middle layer is β-crystal random copolymer polypropylene reinforced by silica fiber, and the material of the inner layer is β-crystal random copolymer polypropylene containing antibacterial masterbatch.

[0137] The material of the outer layer of the pipe is β-crystal random copolymerized polypropylene, which ensures the hot-melt connection of the plastic pipe.

[0138] The material of the middle layer of the pipe is β-crystal random copolymerized polypropylene particles reinforced by silica fiber, the mass fraction of silica fiber in the material of the middle layer is 20-28%, and the length of silica fiber is 4-8 mm. The middle layer of the ...

Embodiment 3

[0188] Please see attached figure 1 , a fiber-reinforced β-crystalline random copolymer polypropylene composite pipe, characterized in that it comprises an outer layer, an intermediate layer and an inner layer, and an intermediate layer is arranged between the outer layer and the inner layer; the material of the outer layer is β-crystalline Type random copolymer polypropylene, the material of the middle layer is silica fiber reinforced β crystal random copolymer polypropylene, and the material of the inner layer is β crystal random copolymer polypropylene containing antibacterial masterbatch.

[0189] The material of the outer layer of the pipe is β-crystal random copolymerized polypropylene, which ensures the hot-melt connection of the plastic pipe.

[0190] The material of the middle layer of the pipe is β-crystal random copolymer polypropylene particle reinforced by silica fiber, the mass fraction of the silica fiber in the material of the middle layer is 24%, and the lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com