Ceramic double arrange packaging device high accelerate centrifugation experiment cramping apparatus

A technology for packaging devices and centrifugal tests, which is applied to centrifuges, instruments, measuring devices, etc., can solve problems such as no layered design of the force-bearing surface of the fixture, difficulty in device positioning, and device failure, so as to avoid the problem of device deformation or fracture, The effect of improving the success rate and production efficiency and reducing the probability of device breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

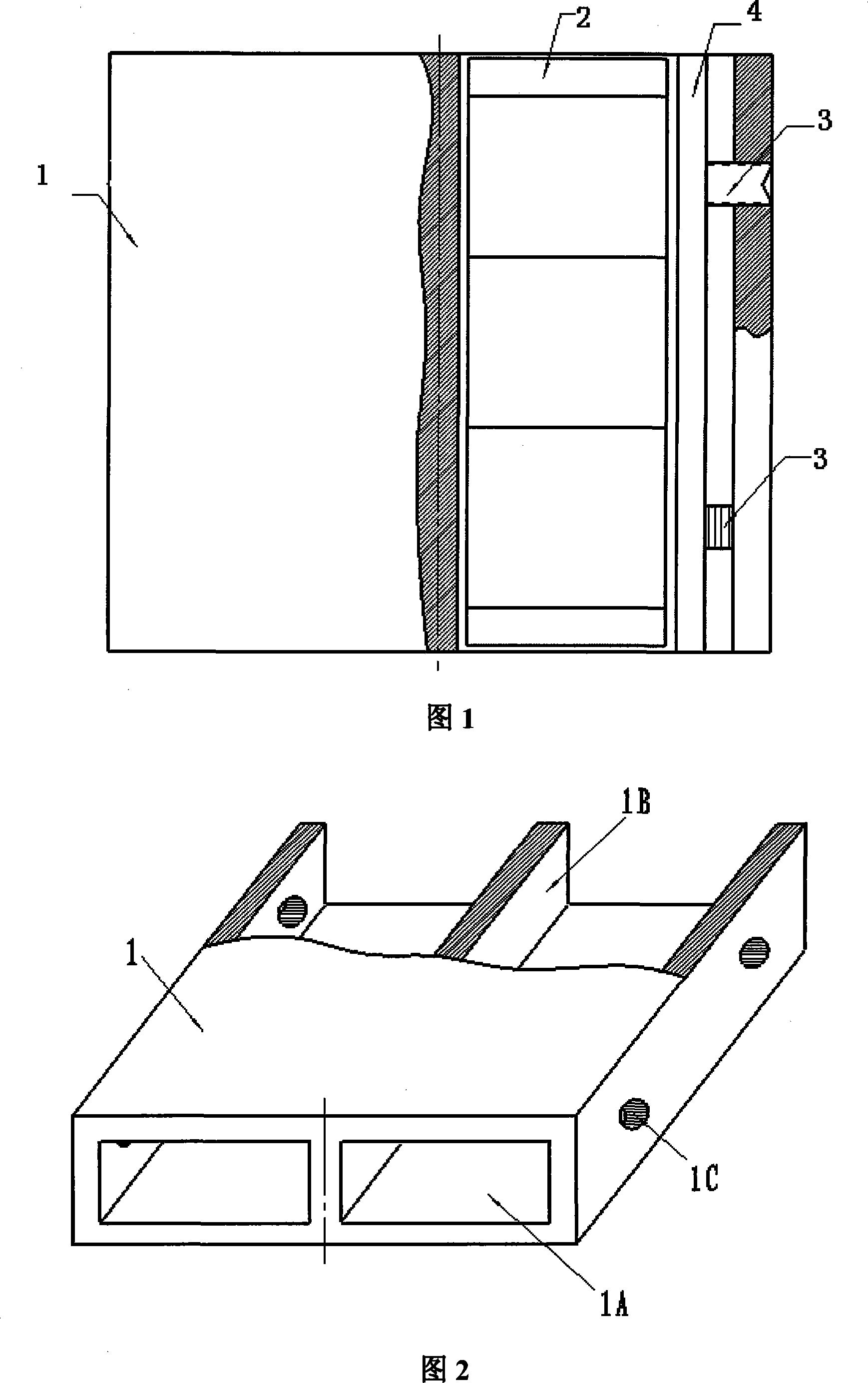

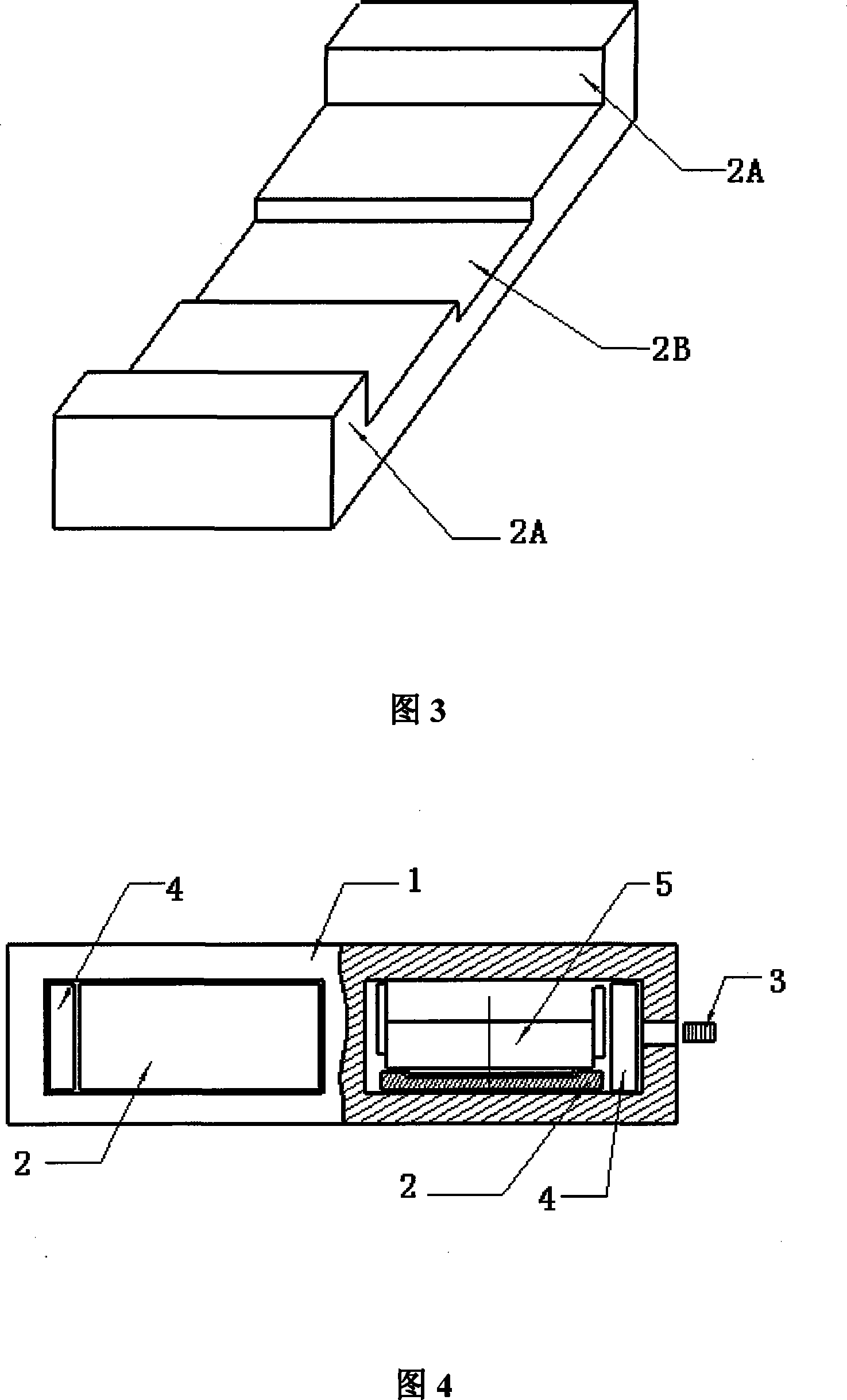

[0025] The structure and use of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The high-acceleration centrifugal test fixture of the present invention adopts a method of inserting a "child-and-mother type combined fixture" into the sliding groove of the metal ring rotor. The mother fixture is a standard-volume block shape with built-in standard through slots; the sub-fixture is a drawer-type shape, which can be designed as a sub-fixture of different sizes according to the specific dimensions of the device. After the components are installed, the sub-fixture is directly placed in the through slot of the mother fixture. After the two sides are locked, a plate-like whole is formed, which can be installed in the chute of the metal ring rotor in any direction.

[0027] The high-acceleration centrifugal test fixture of the present invention includes a mother fixture 1, a sub fixture 2 for holding the device to be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com