Substrate for processing cutter and manufacturing method of substrate and drill bit using substrate

A technology for processing tools and manufacturing methods, which is applied to twist drills and other directions, can solve the problems of non-wear-resistant drill tips and easy breakage of spiral grooves, and achieve the effects of reducing the probability of drill breakage, improving wear resistance, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

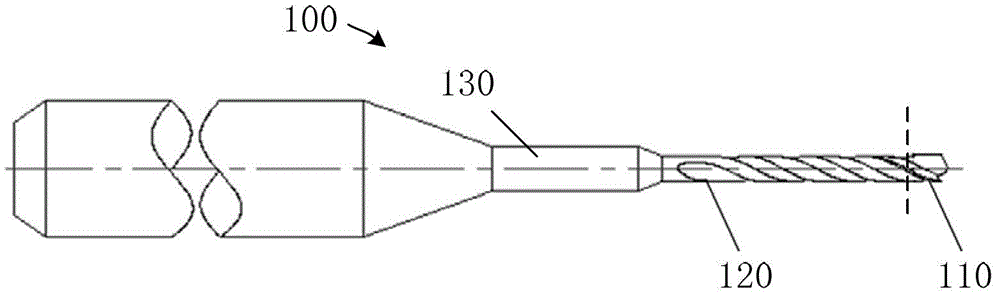

Image

Examples

Embodiment 2

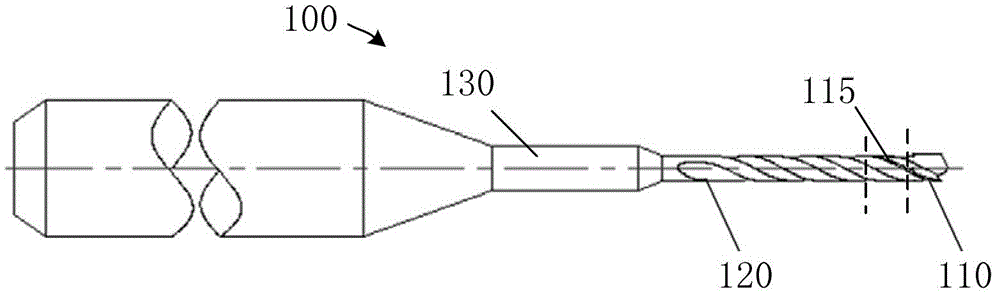

[0033] Different from Embodiment 1, the drill bit of this embodiment has three alloy segments with different hardness, such as figure 2 As shown, the hardness of the cemented carbide of the drill tip section 110 is the largest, and the drill body section 120 also has two alloy sections with different hardness, one section is close to the transition section 115 of the drill tip section 110, and the hardness of the transition section 115 is smaller than that of the drill tip section 110 hardness but greater than the hardness of the alloy section near the tail of the drill.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com