Semiconductor film thickness measurement calibration standard sheet and manufacturing method thereof

A standard wafer, film thickness technology, applied in semiconductor devices, semiconductor/solid-state device testing/measurement, semiconductor/solid-state device components, etc., can solve the problem of high price, increase the risk of damage to standard wafers, and spend a lot of time and other problems to achieve the effect of improving work efficiency, reducing the probability of fragmentation and control efficiency, and saving expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

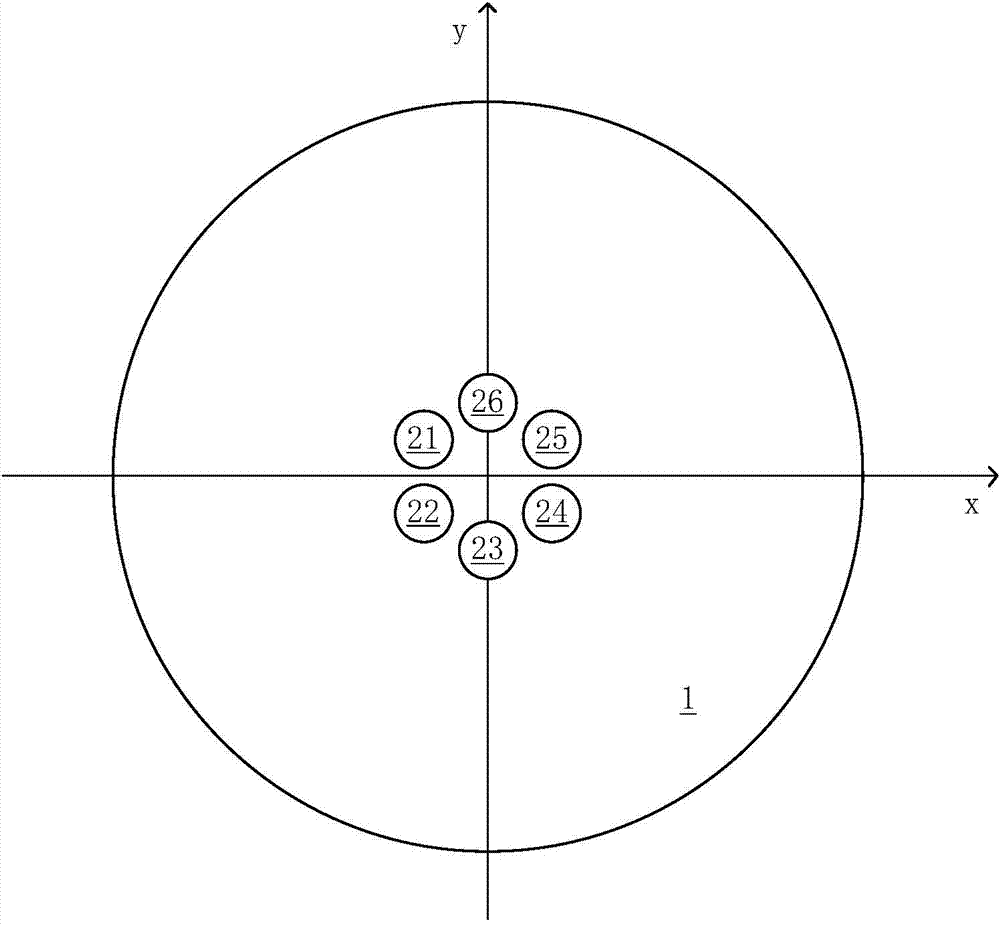

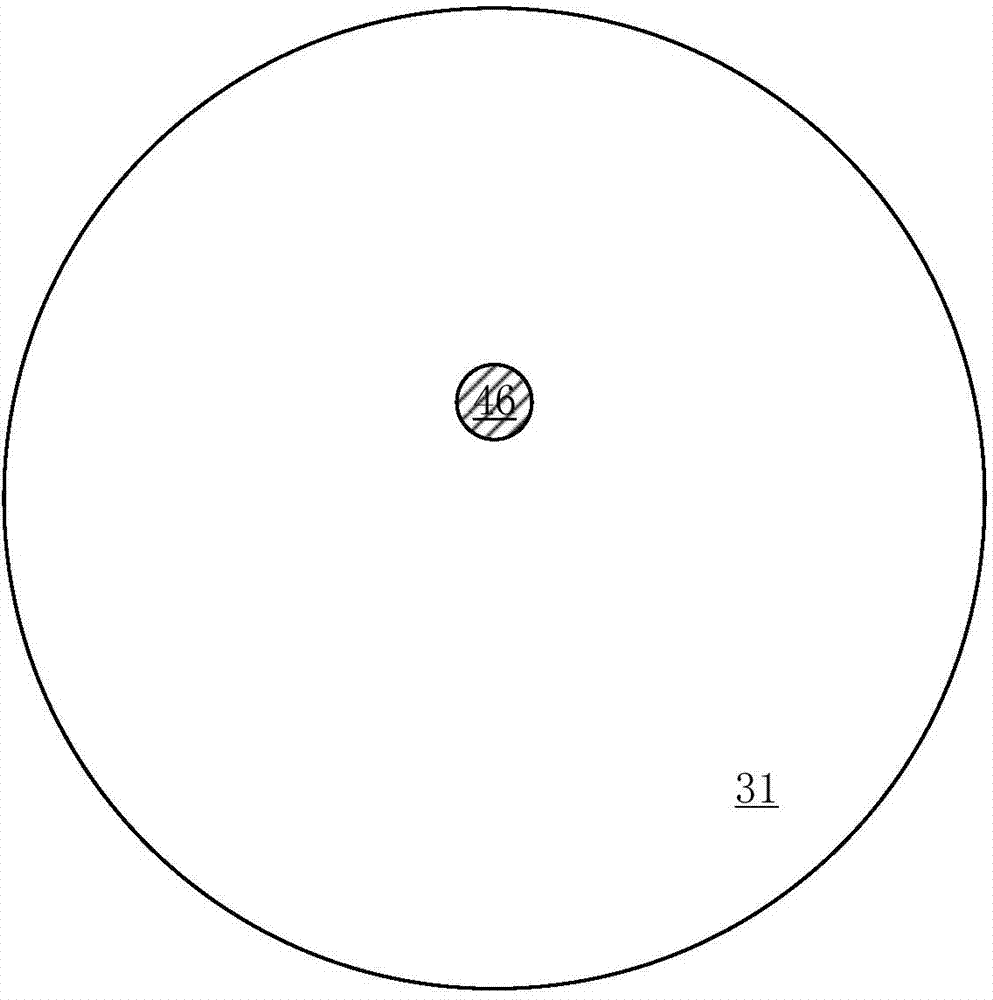

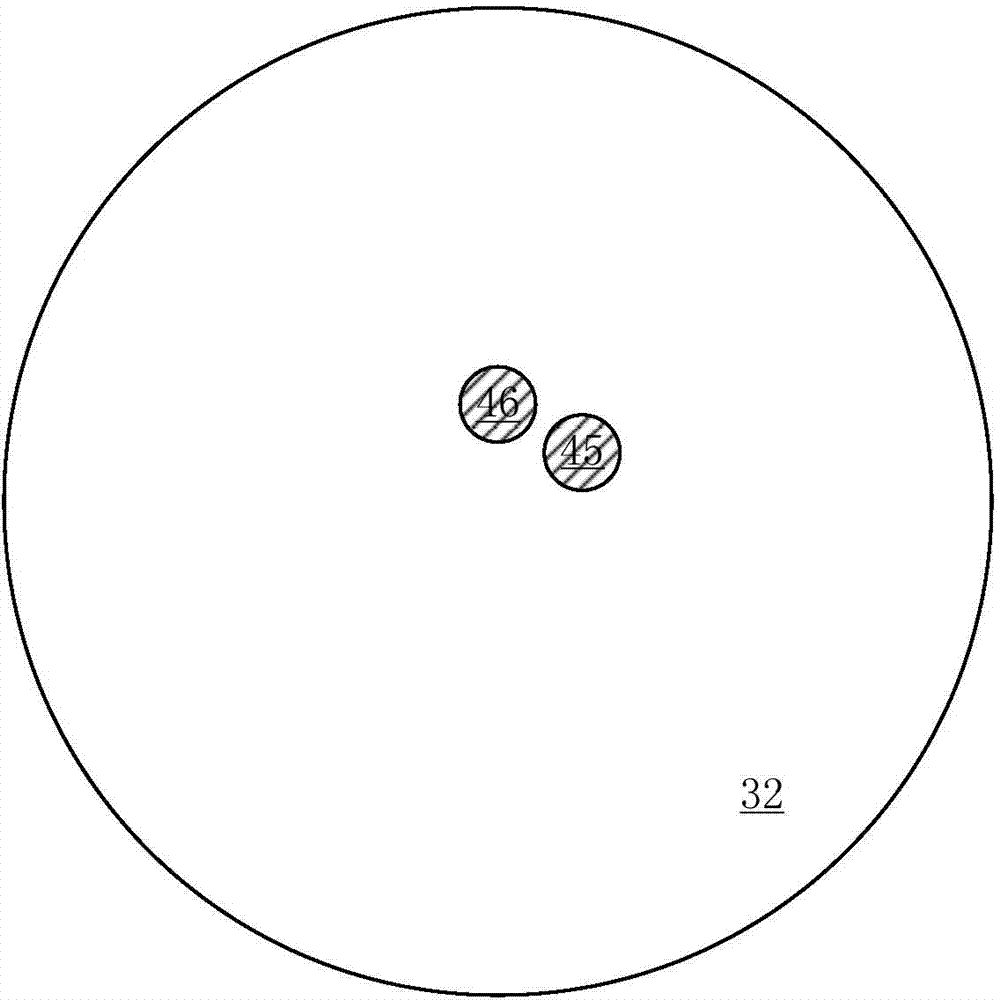

[0060] The semiconductor film thickness measurement calibration standard sheet provided by the present invention includes a wafer substrate and at least two pattern areas of different film thickness levels located on the surface of the wafer substrate. Wherein, the number of pattern areas can be adjusted according to the film thickness measuring machine and the need for film thickness measurement. Those skilled in the art can expand the pattern area of the embodiment according to the introduction of the following embodiments combined with the existing technology in the field Or to reduce the number to the required number, the position of each pattern area on the wafer substrate can also be adjusted arbitrarily in combination with the introduction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com