Liquid crystal display panel, array substrate and manufacturing method of array substrate

An array substrate and substrate technology, applied in the field of liquid crystal display, can solve the problems of increasing the black matrix and reducing the pixel aperture ratio, and achieve the effect of increasing the pixel aperture ratio, reducing the size, and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions of the exemplary embodiments provided by the present invention with reference to the accompanying drawings in the embodiments of the present invention.

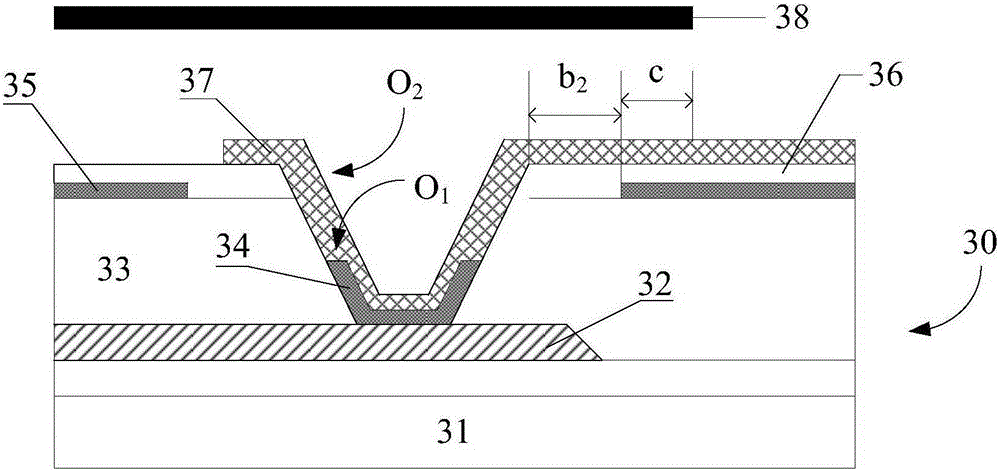

[0022] image 3 is a structural cross-sectional view of an embodiment of the array substrate of the present invention. Such as image 3 As shown, the array substrate 30 includes a substrate 31 , a metal layer 32 , a first passivation layer 33 , a floating electrode layer 34 , a common electrode layer 35 , a second passivation layer 36 and a pixel electrode layer 37 .

[0023] Wherein, the metal layer 32 is formed on the substrate 31; the first passivation layer 33 is formed on the metal layer 32 and is formed with a first contact hole O that exposes the surface of the metal layer 32 1 ; The floating electrode layer 34 covers the first contact hole O 1 The bottom surface of and the first contact hole O connected to the bottom surface 1 A part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com