Method for predicting residual tensile strength of ceramic-based composite material in stress oxidation environment

A composite material and tensile strength technology, used in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as the inability to accurately predict the residual tensile strength of unidirectional SiC/SiC composites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0146] Below in conjunction with embodiment the present invention will be further described.

[0147] Taking the unidirectional SiC / C / SiC composite material in a pure oxygen environment with an ambient temperature of T∈(900~1200°C) and an ambient pressure of P=100KPa as an example, calculate its performance at different oxidation times, stress levels, and temperatures. Residual tensile strength of unidirectional SiC / C / SiC composites, where SiCSiC fibers are NicalonSiC fibers from Nippon Carbon Corporation.

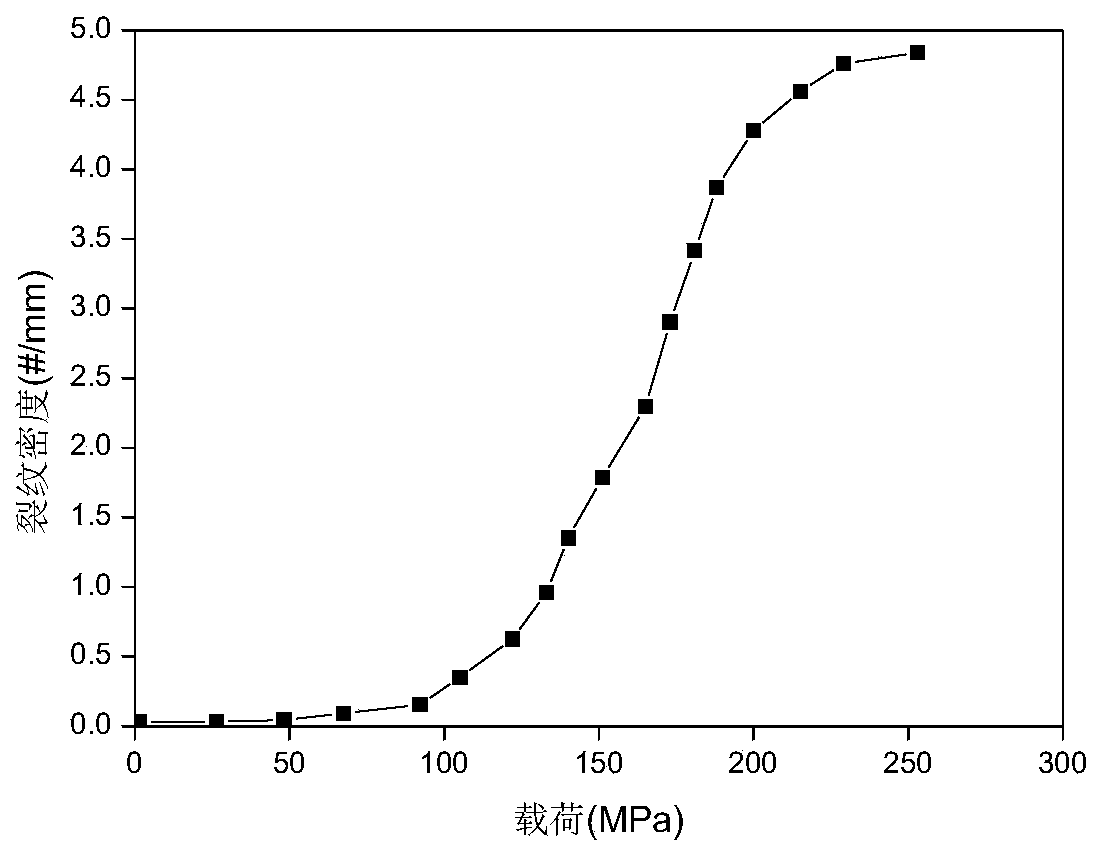

[0148] (1) Determine the change law of the saturation crack spacing of the SiC matrix of the unidirectional SiC / SiC composite material and the average spacing of the SiC matrix cracks with stress;

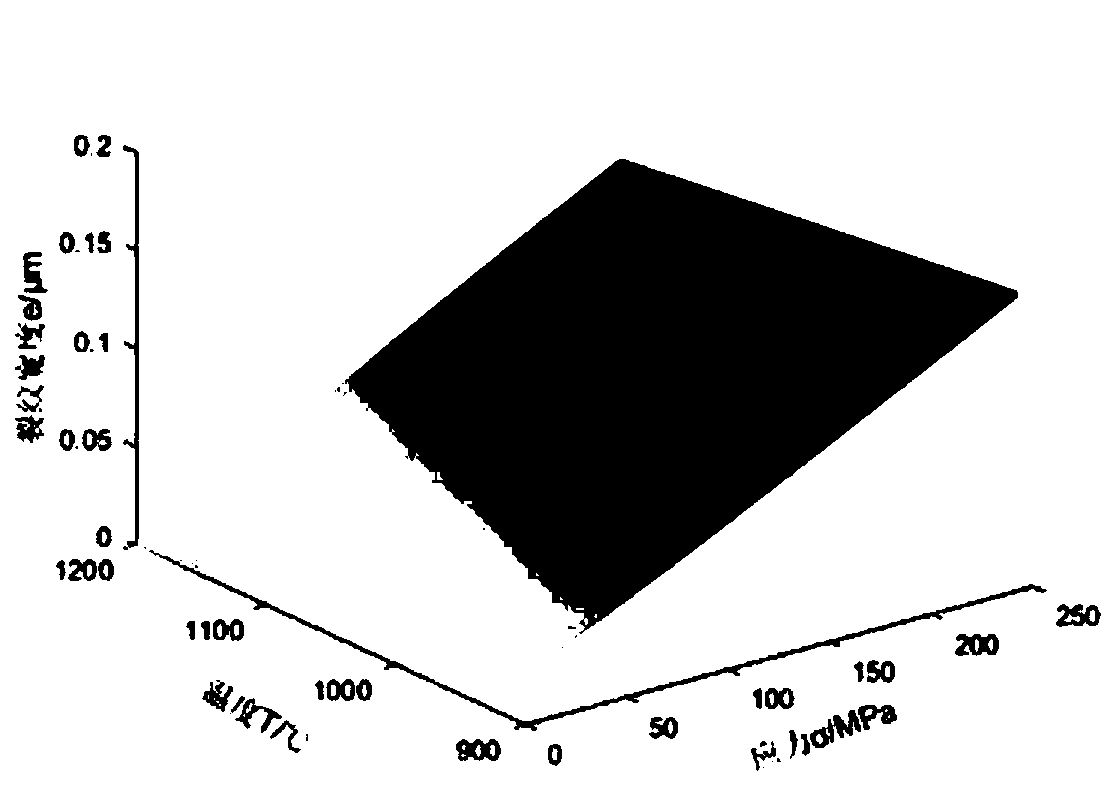

[0149] (2) Determine the change law of crack width of SiC matrix with stress and temperature;

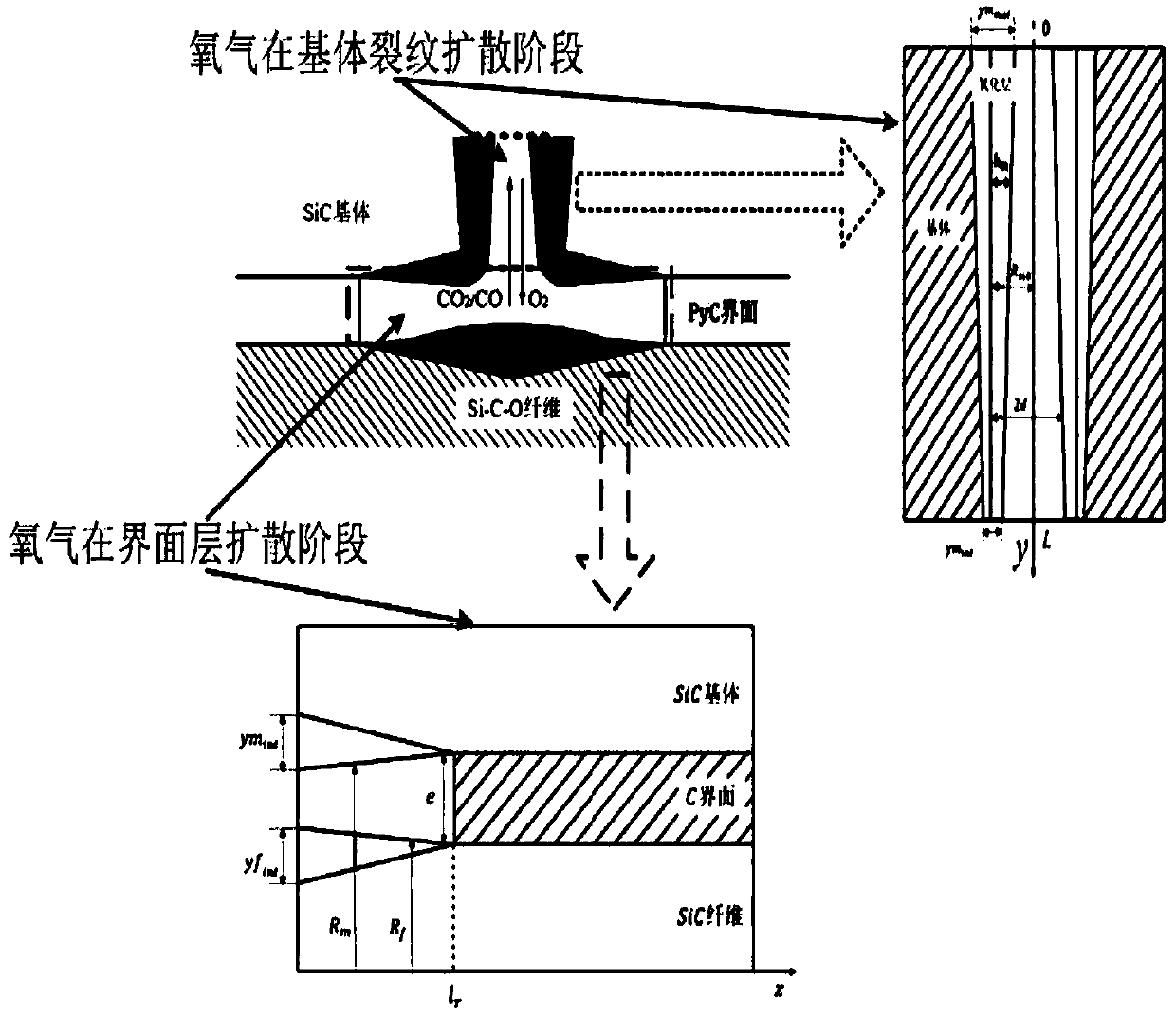

[0150](3) Establish the unidirectional SiC / SiC composite material stress oxidation kinetic equation and boundary conditions, and use the classical fourth-order Runge-Kutta method to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com