A Prediction Method for Residual Tensile Strength of Ceramic Matrix Composites in Stress Oxidation Environment

A composite material and tensile strength technology, which is applied in the field of residual tensile strength prediction of ceramic matrix composite materials in stress oxidation environment, can solve the problem that the residual tensile strength of unidirectional SiC/SiC composite materials cannot be accurately predicted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0147] Below in conjunction with embodiment the present invention will be further described.

[0148] Taking the unidirectional SiC / C / SiC composite material in the environment of T∈(900~1200℃) and ambient pressure P=100KPa pure oxygen as an example, calculate its performance under different oxidation times, different stress levels and different temperatures. Residual tensile strength of unidirectional SiC / C / SiC composites, where SiCSiC fibers are NicalonSiC fibers from Nippon Carbon Corporation.

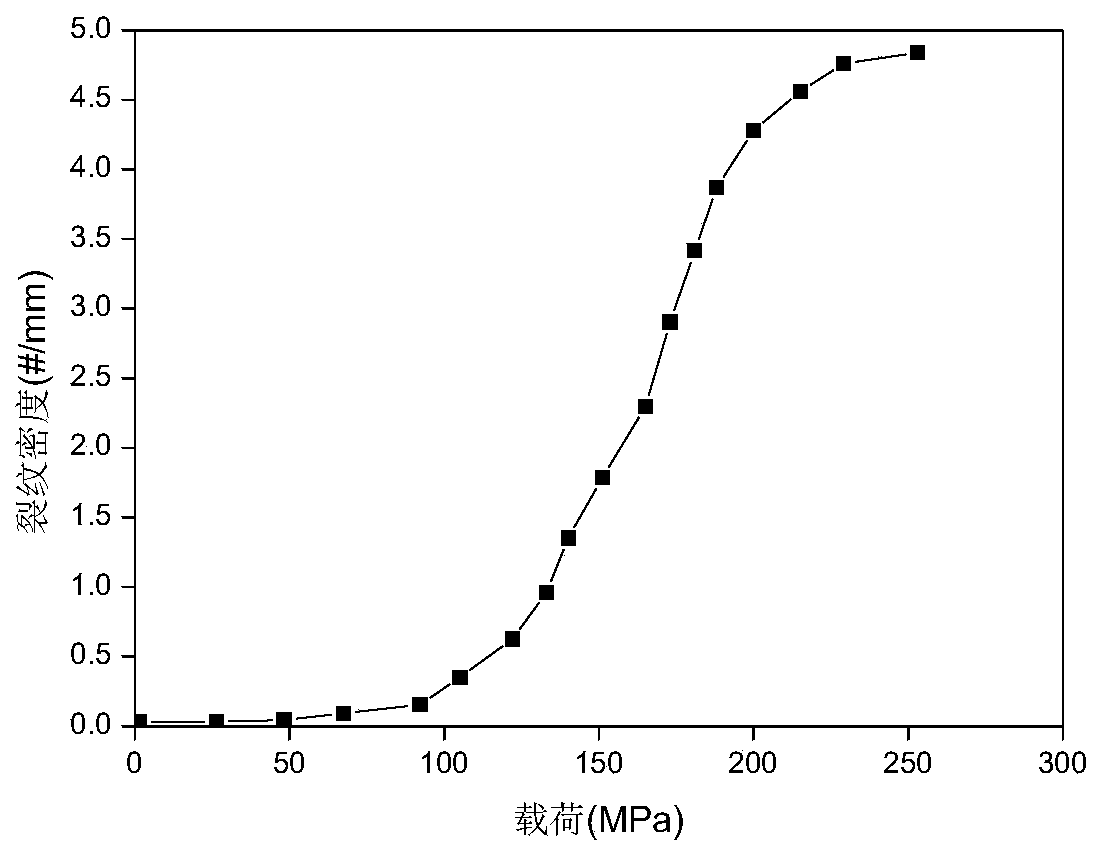

[0149] (1) Determine the change law of the saturation crack spacing of the SiC matrix of the unidirectional SiC / SiC composite material and the average spacing of the SiC matrix cracks with stress;

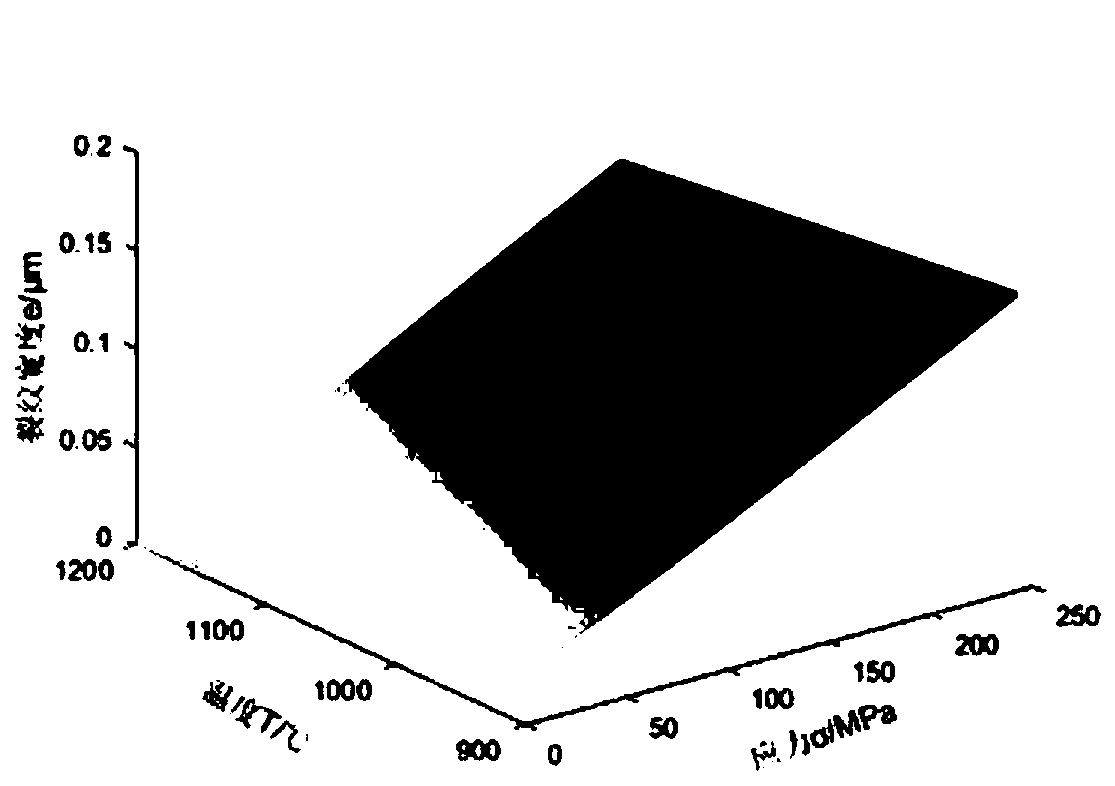

[0150] (2) Determine the change law of crack width of SiC matrix with stress and temperature;

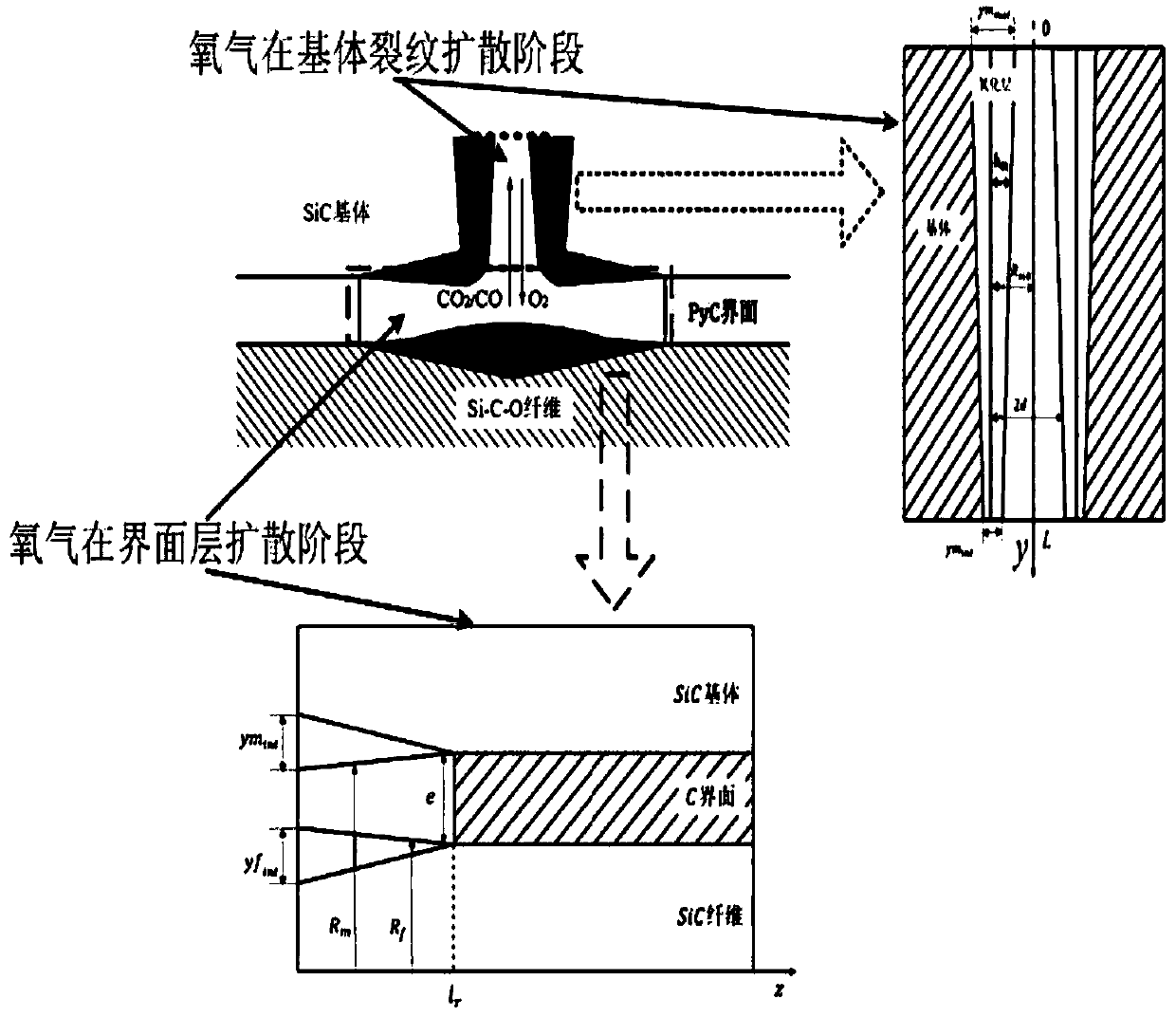

[0151](3) Establish the unidirectional SiC / SiC composite material stress oxidation kinetic equation and boundary conditions, and use the classical fourth-order Runge-Kutta method to solve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com