Transfer box for cleaning of silicon wafers

A silicon wafer cleaning and turnover box technology, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of easy slipping of silicon wafers, insufficiency of taking and placing silicon wafers, high pressure on silicon wafers, etc. Putting operation, reducing the chance of fragmentation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

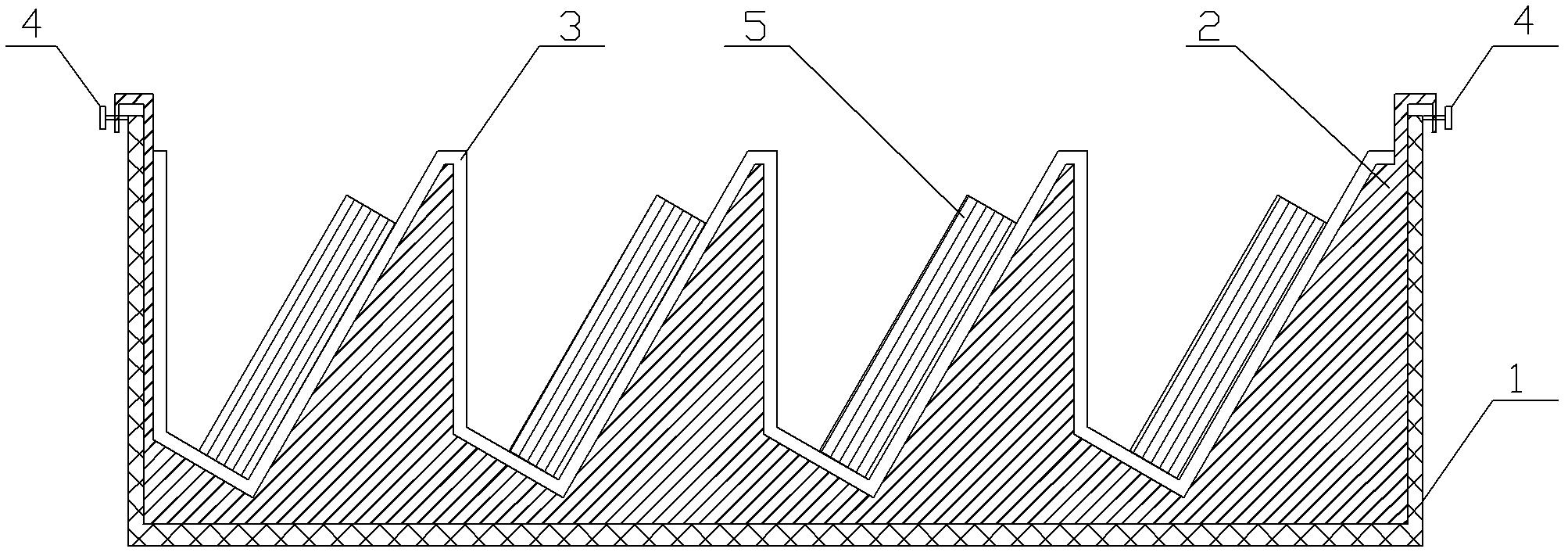

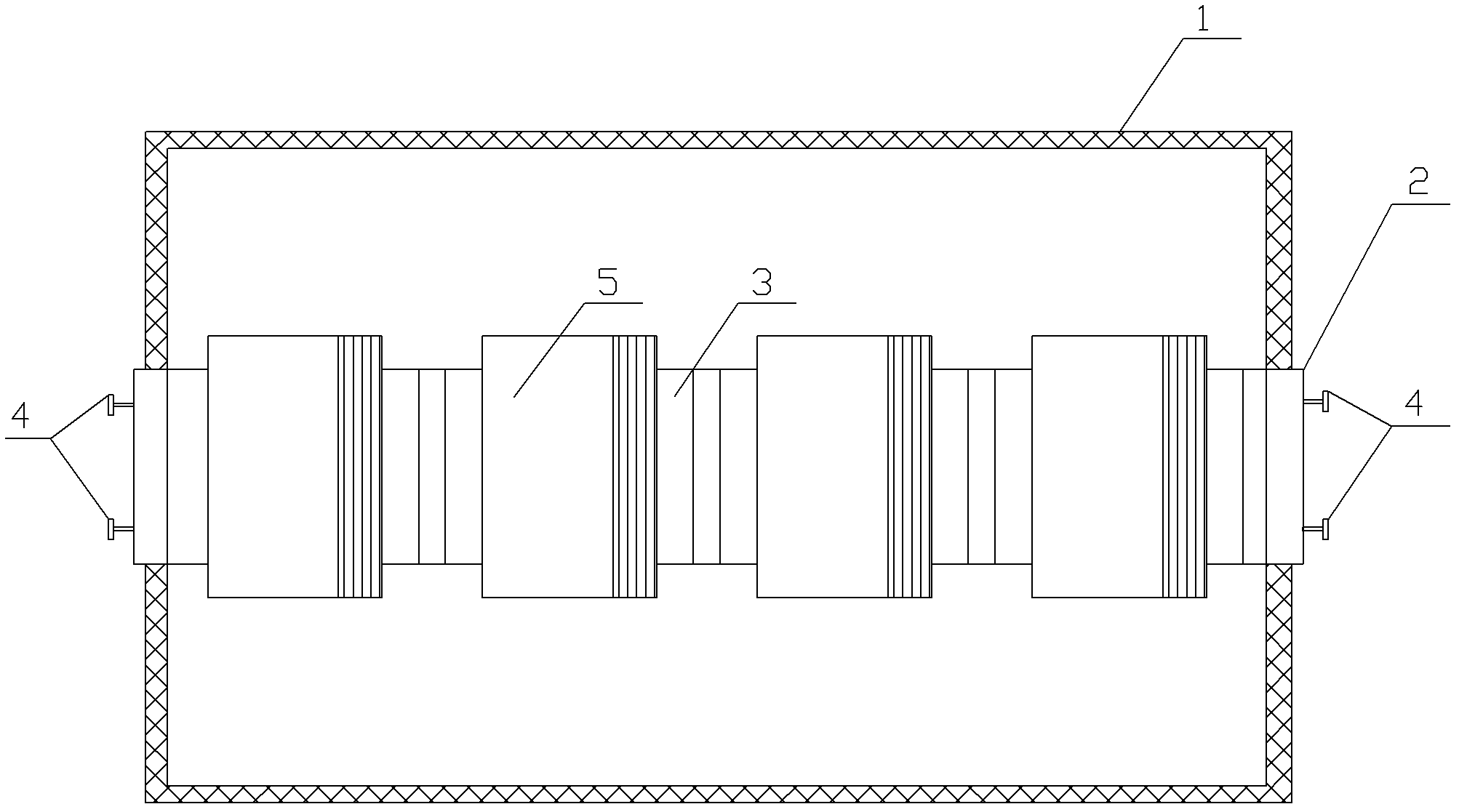

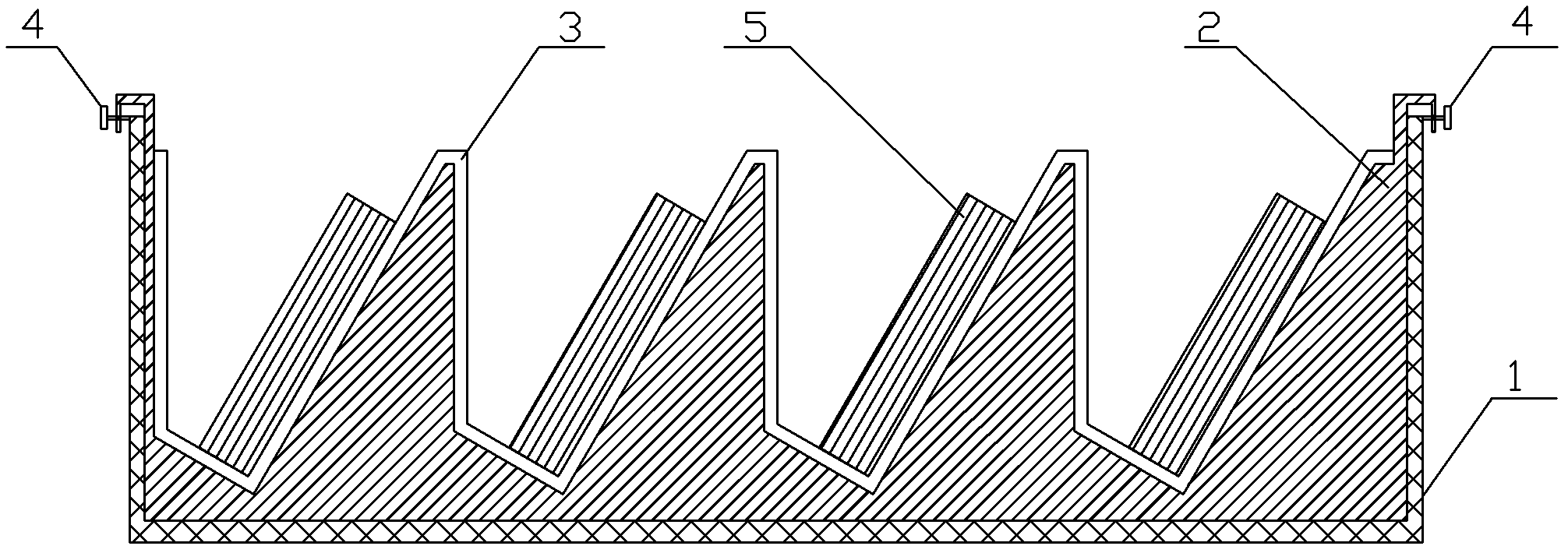

[0016] Please refer to figure 1 and figure 2 As shown, in this embodiment, a silicon wafer cleaning turnover box includes a box body 1, the box body 1 is a rectangular structure, made of plastic, and a bracket 2 is detachably arranged in it, and the bracket The frame 2 has four V-shaped grooves for placing the silicon wafer 5, and the width of the bracket 2 is smaller than the width of the silicon wafer 5, and its surface is covered with a rubber pad 3 for anti-skid and shock absorption.

[0017] In actual use, the bracket 2 is first fixed in the box body 1 by bolts 4, and then the box body 1 is filled with water. When placing the silicon wafer 5, the silicon wafer 5 can be gently placed on the rubber pad 3 in the V-shaped groove on the bracket 2, and the center line of the silicon wafer 5 is bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com