Steel railroad rail breakage fault analyzing and warning method and steel railroad rail breakage fault analyzing and warning system

A fault analysis and rail technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large factor variable matrix, complex calculation, and difficult data acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

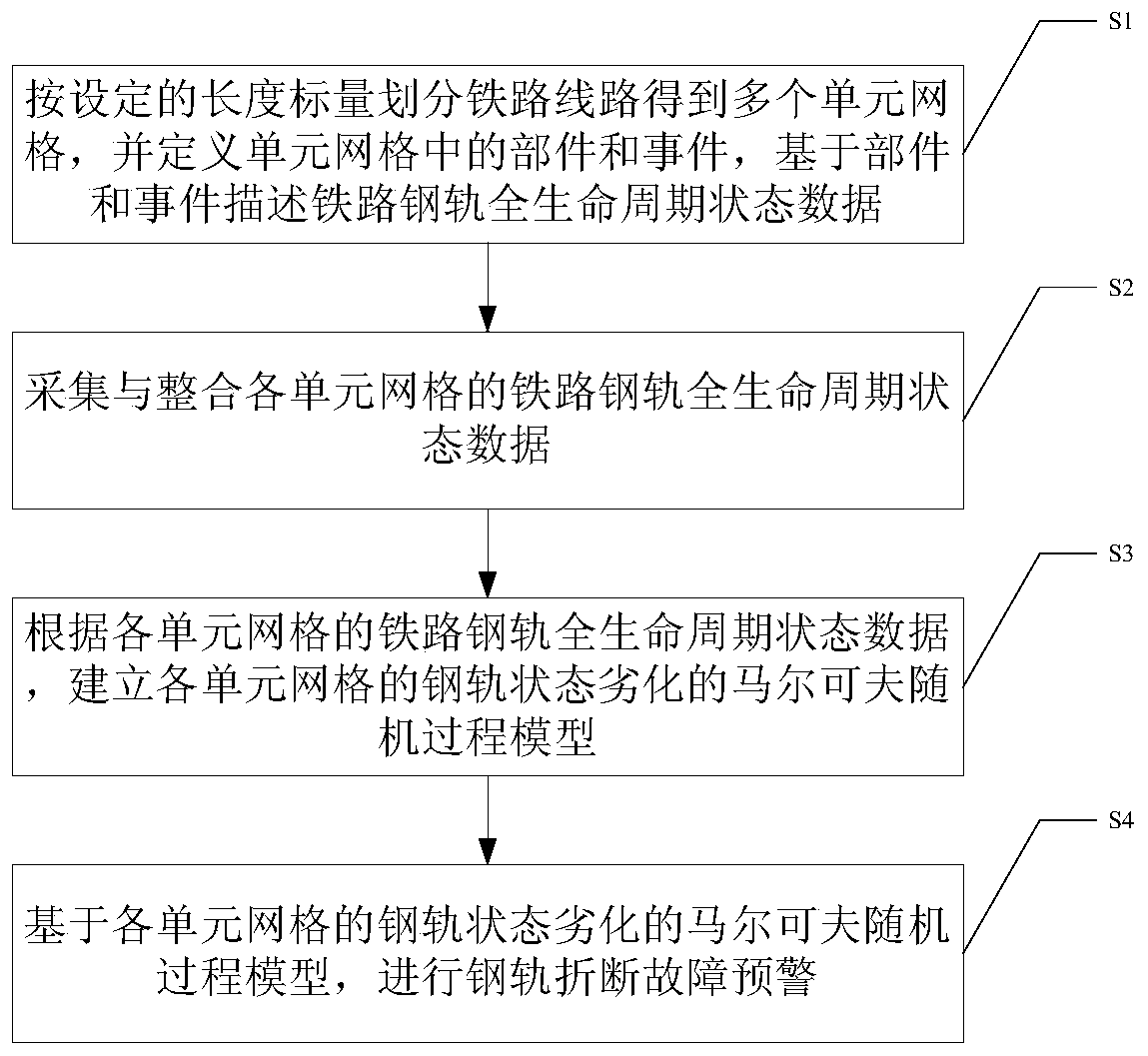

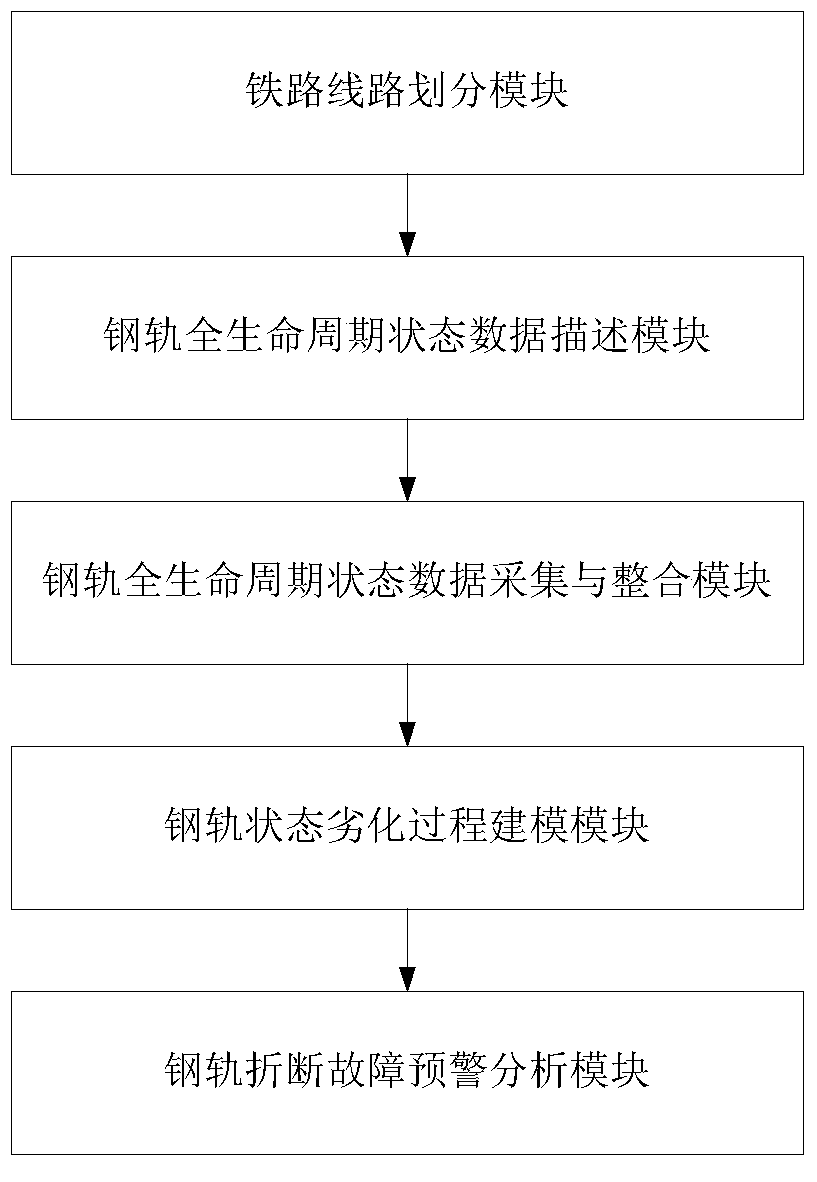

[0039] like figure 1 As shown, the railway rail fracture analysis and early warning method provided in this embodiment includes the following steps:

[0040] Step1. Divide the railway line according to the set length scalar to obtain multiple unit grids, and define the components and events in the unit grids, and describe the state data of the whole life cycle of railway rails based on components and events;

[0041] Step2. Collect and integrate the rail life cycle status data of each unit grid;

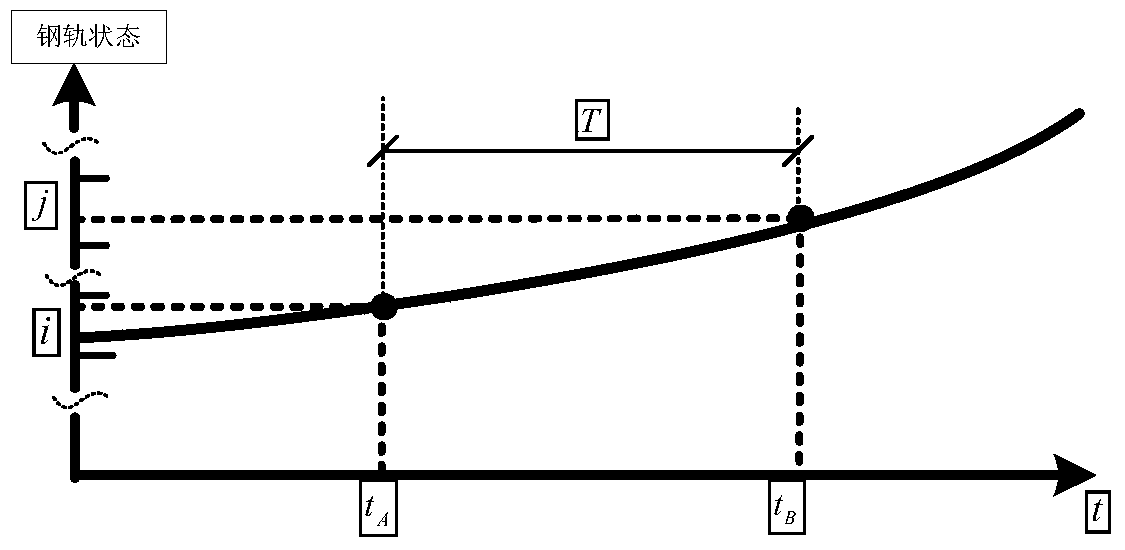

[0042] Step3. According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com