Axial-flow fan blade handling vehicle

A technology of axial flow fan blades and turnover car is applied in the field of tools for transportation and storage of objects, which can solve the problems of low utilization rate of site area, easy damage to injection molding parts, increase of worthless labor, etc., so as to improve the utilization rate of site and ensure Quality, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

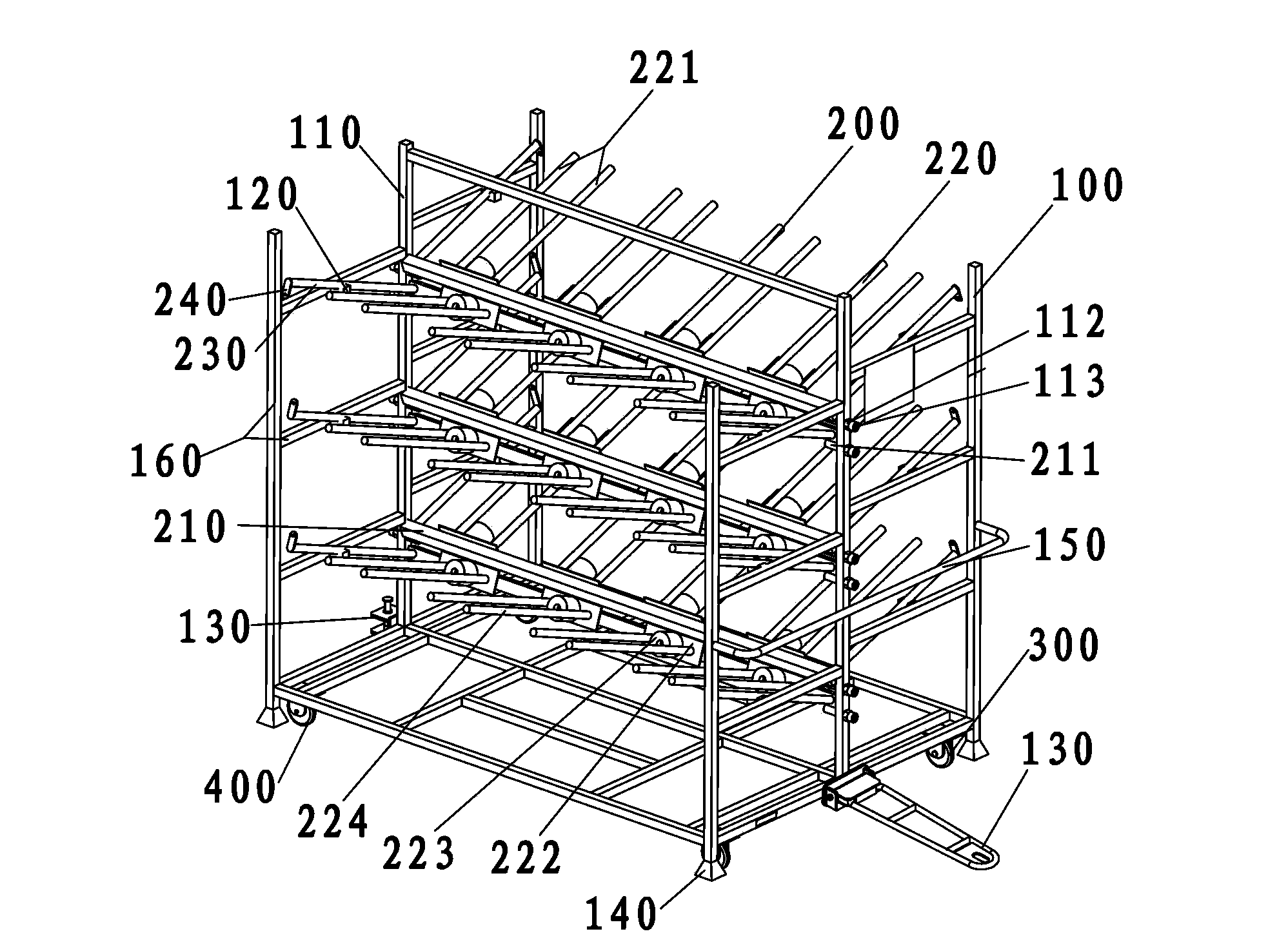

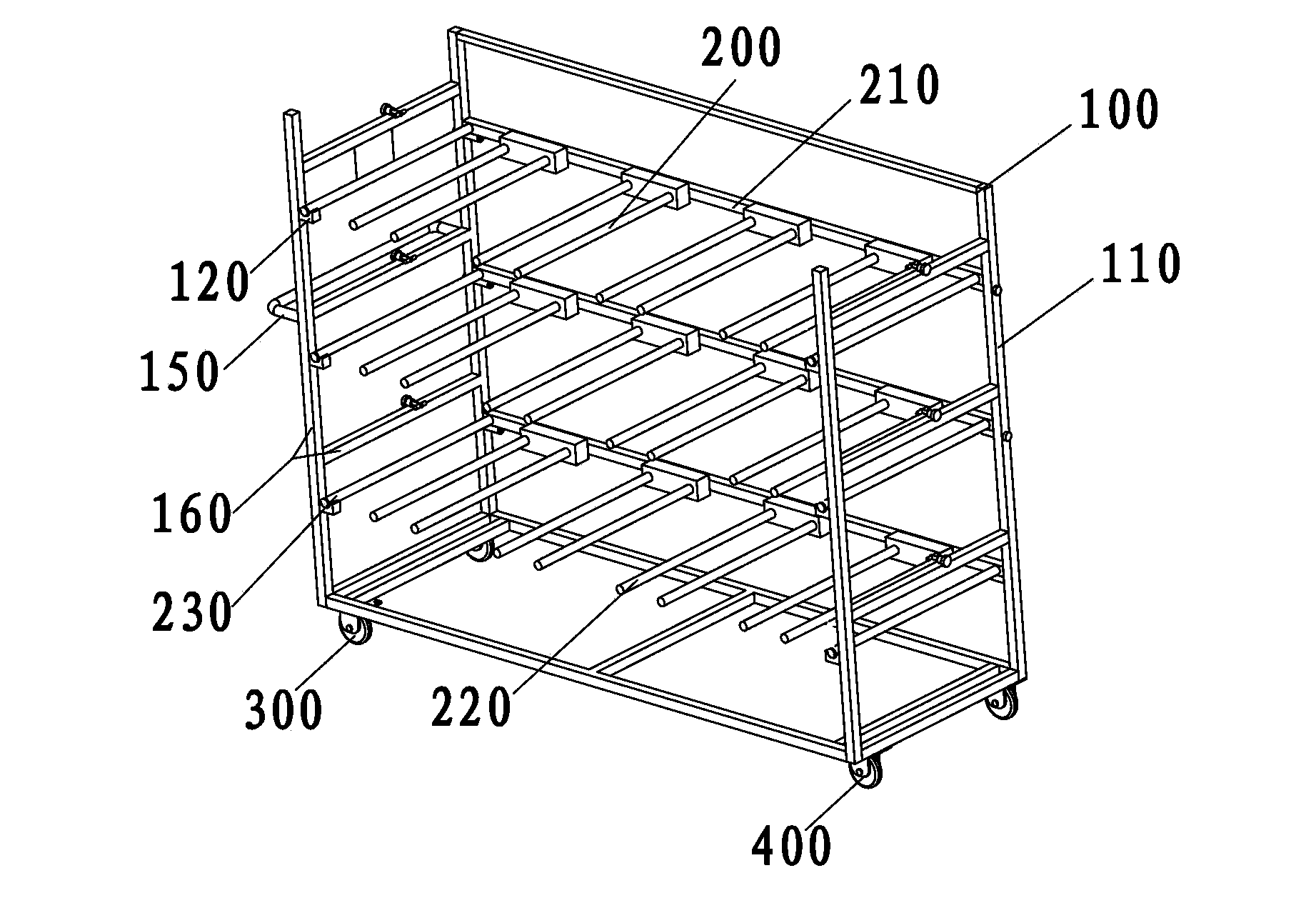

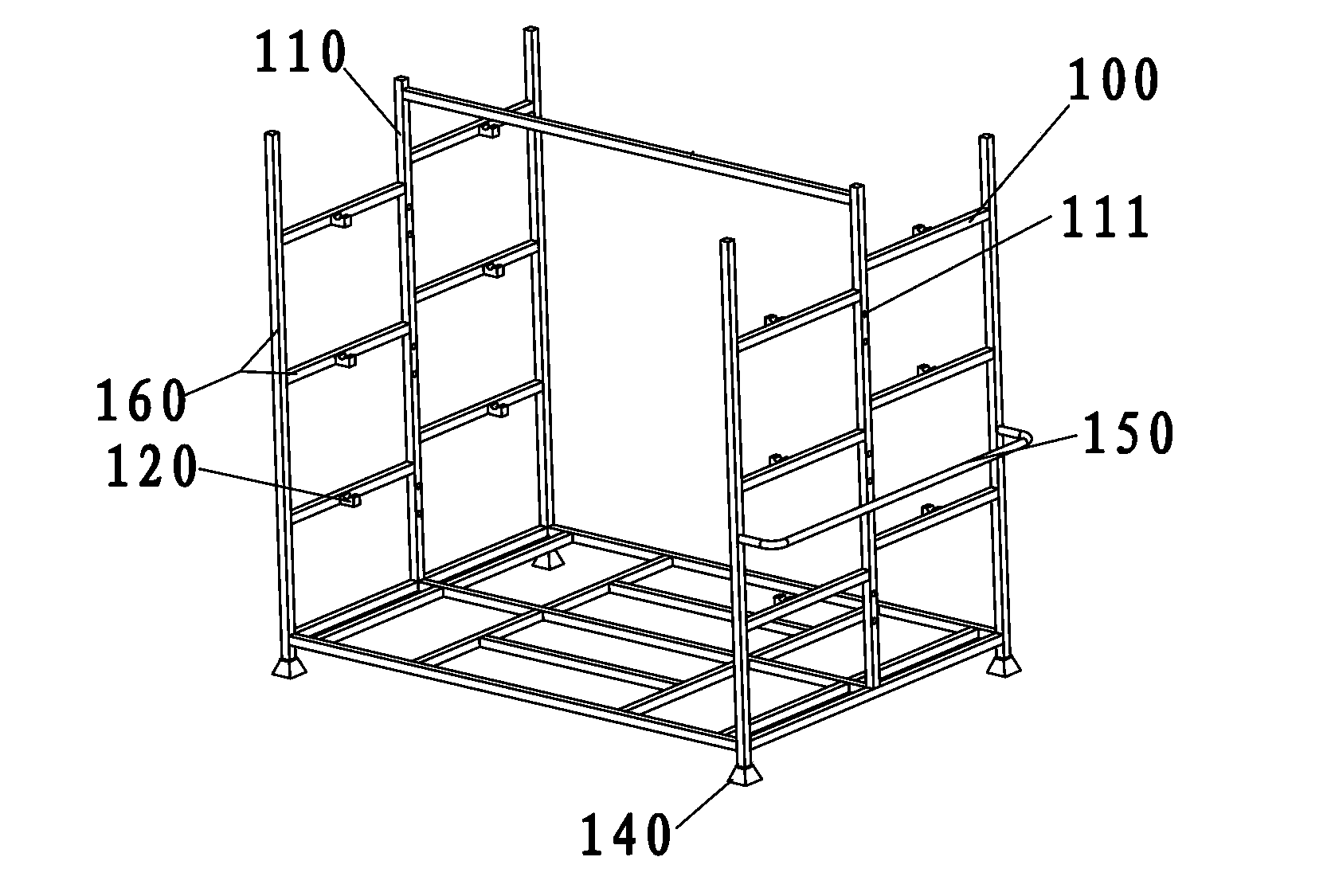

[0041] like Figure 1 to Figure 5 As shown, in one embodiment of the present invention, the turnover vehicle for axial flow fan blades of the present invention includes a main body frame 100 and at least one spacer frame 200, and the spacer frame 200 can be fixed on the main body frame 300;

[0042] The compartment frame 200 includes a connecting rod 210 and four axial fan blade storage racks 220, the four axial fan blade storage racks 220 are fixed on the connecting rod 210, and the connecting rod 210 is connected to the Main frame 100;

[0043] The axial fan blade storage rack 220 includes two storage rods 221 . like Figure 4 , Figure 5 shown.

[0044] The two storage rods 221 pass through the gap between the blades of the axial-flow fan, so that the axial-flow fan is placed on the storage rack 220 of the axial-flow fan stably. A plurality of axial flow blades can be stacked on each of the axial flow blade storage racks 220 .

[0045] Preferably, as an embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com