Cloth inspecting machine for textile cloth

A technology of textile cloth and cloth inspection machine, which is applied in the inspection of textile materials, textiles and papermaking, thin material processing, etc. It can solve problems such as poor flatness, excessive stretching of cloth, and wrinkles on the surface, and achieves strong practicability , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

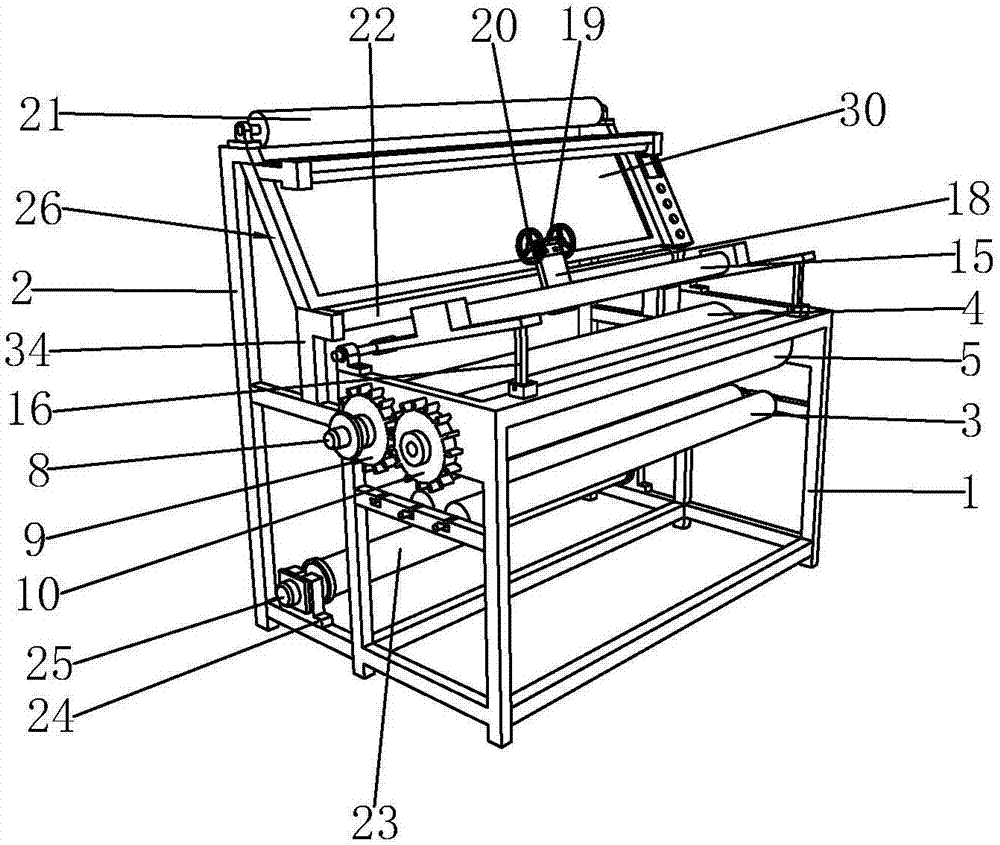

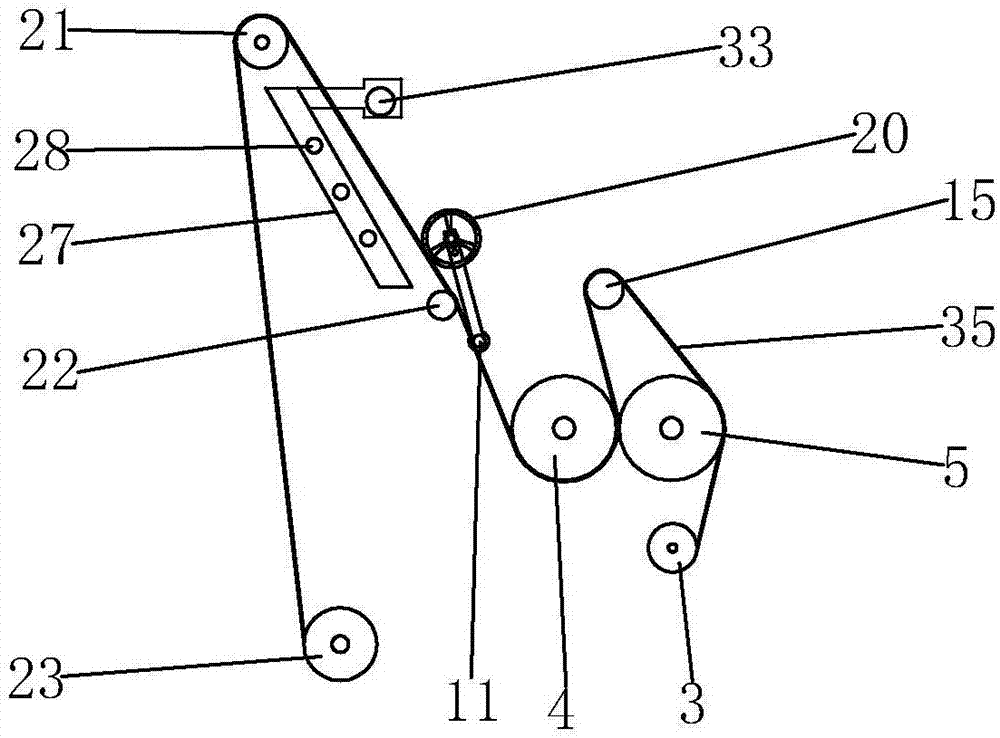

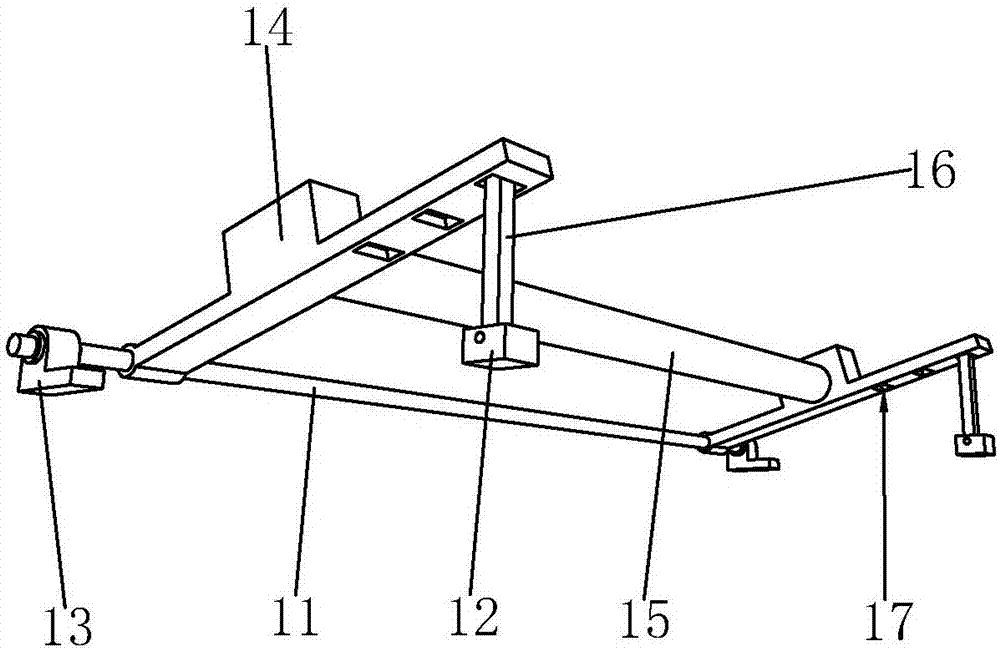

[0023] Such as Figure 1 to Figure 5 As shown, it is a cloth inspecting machine for textile cloth of the present invention, comprising a frame 1 and a support frame 2, the support frame 2 is arranged on both sides of the frame 1, and the frame 1 is respectively provided with a cloth releasing roller 3, Main pressing roller 4 and secondary pressing roller 5, cloth 35 is wound around cloth putting roller 3, both sides of frame 1 are all provided with mounting plate 6, are evenly distributed with L-shaped embedding groove 7 on the mounting plate 6, L-shaped embedding The position groove 7 connects the two ends of the cloth release roller 3, and the design of the L-shaped embedding groove 7 can facilitate the clamping between the cloth release roller 3 and the mounting plate 6. When installing, put the two ends of the cloth release roller 3 along the L-shaped The vertical surface of the interlocking groove 7 moves downward and then moves horizontally, so that the cloth releasing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com