Composite round-link chain forming mold

A technology for composite materials and forming molds, which can be applied to home appliances, other home appliances, household components, etc. It can solve the problems of complex mold design, difficulty in forming, and no manufacturing process, so as to achieve a good pressing effect and solve the effect of closed series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

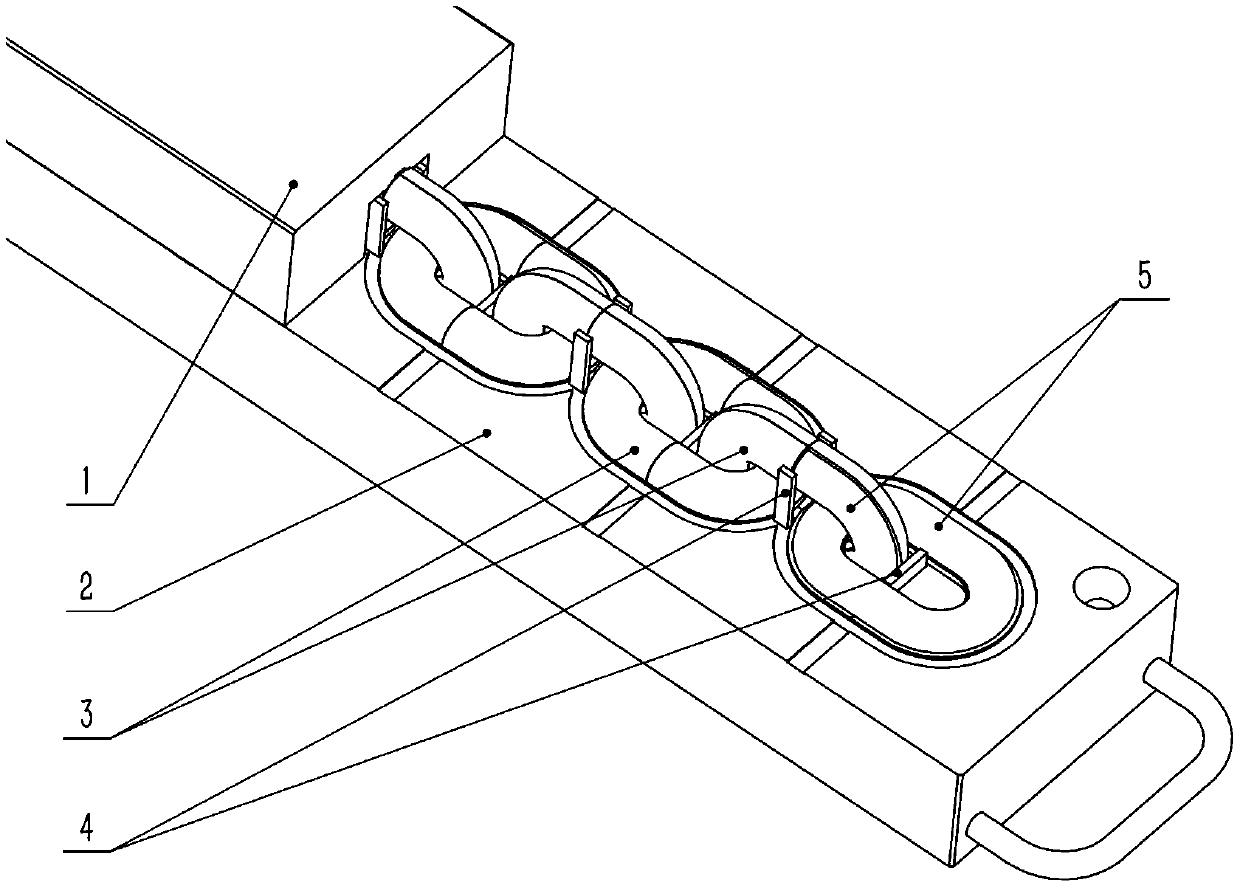

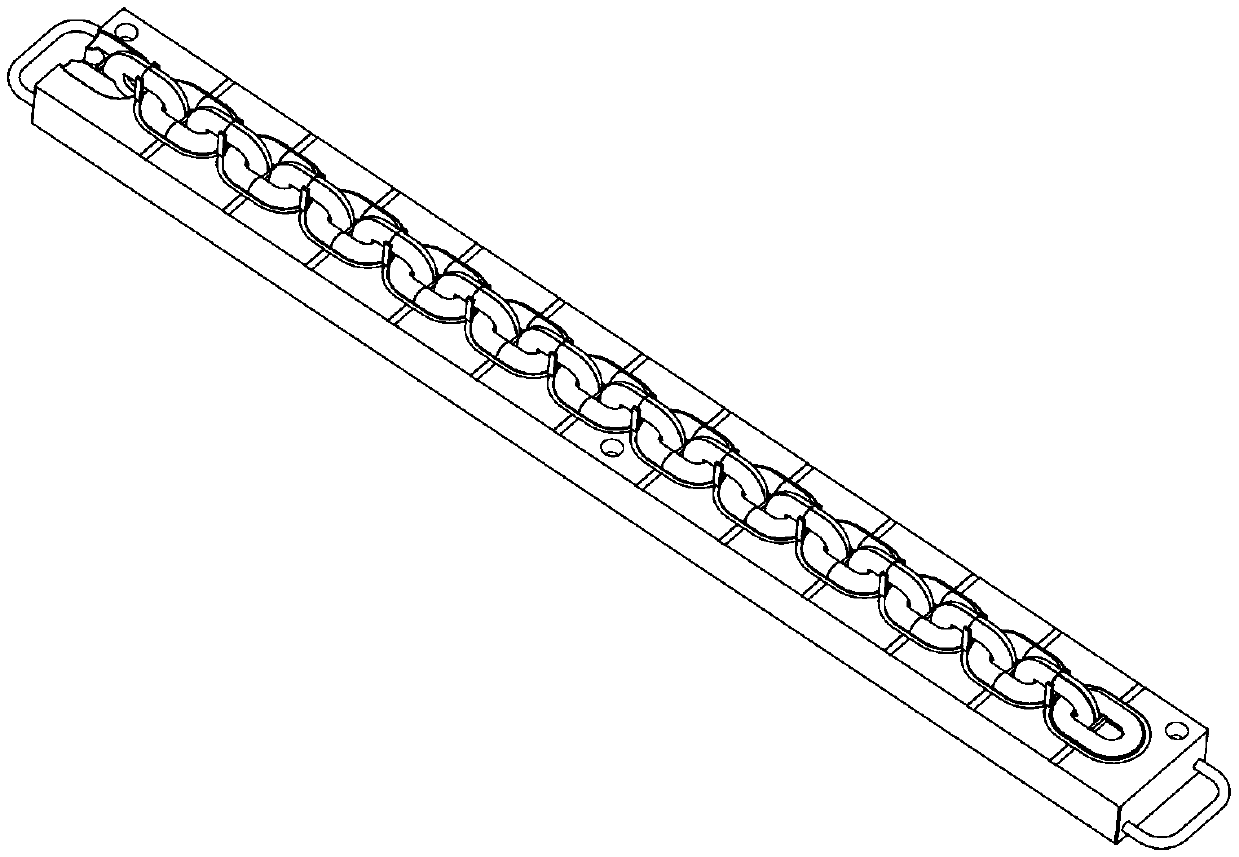

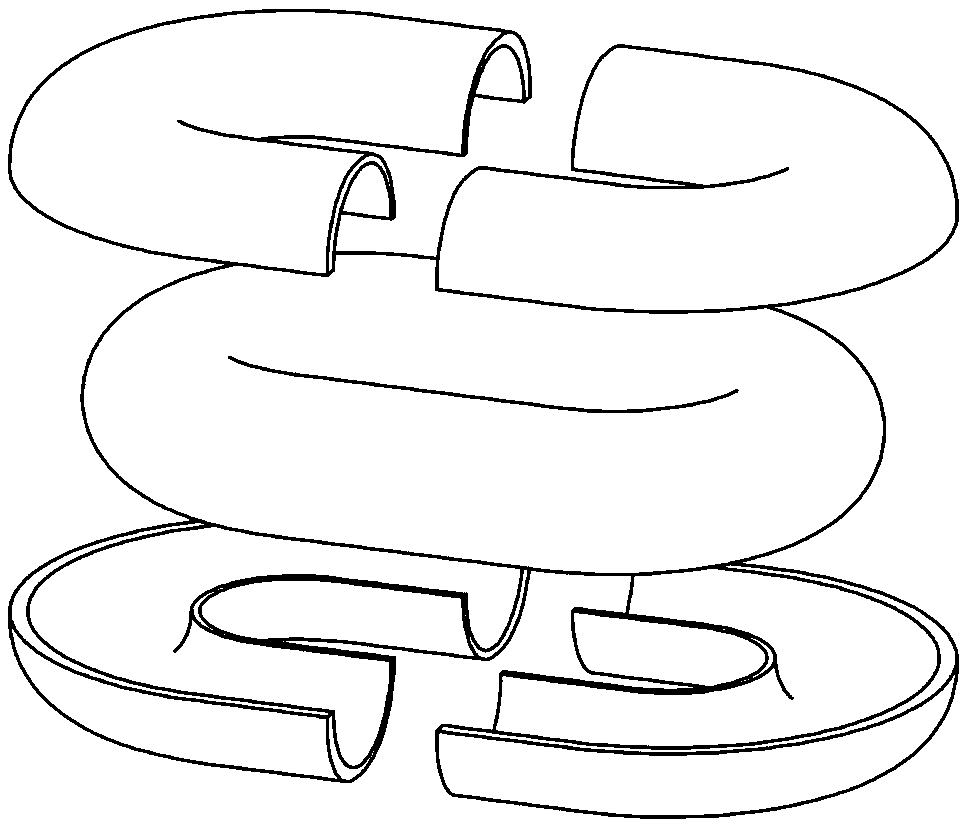

[0022] figure 1 Shown is a schematic diagram of the assembly of the compound material circular chain forming mold. The whole set of mold is composed of an upper mold 1, a lower mold 2, a circular link chain link mold cover 3 and an auxiliary positioning piece 4. When forming, the prepreg is wound into the ring link 5 first, and then it is pre-pressed with a special tooling, and then each ring link 5 is set in the ring link mold cover 3, in order to It is convenient for demoulding and thermoforming, and each round link link 5 will be matched with four round link link die sets 3 . Place each circular link link 5 covered with the circular link link mold cover 3 in the corresponding position of the lower mold 2 . The auxiliary positioning piece 4 is welded on the lower mold 2, and has a certain gap with the circular link link mold cover 3, which can effectively separate each circular link link mold cover 3, and each circular link link mold cover 3 and the upper mold 1 It plays a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com