Powder sintering porous filter alloy, preparation method thereof and pre-pressing molding body for preparing powder sintering porous filter alloy

A pre-compression molding and powder technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of difficult control of material pore size, excessive material tortuosity factor, and influence on permeability, etc., to achieve superior corrosion resistance, Good corrosion resistance, the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

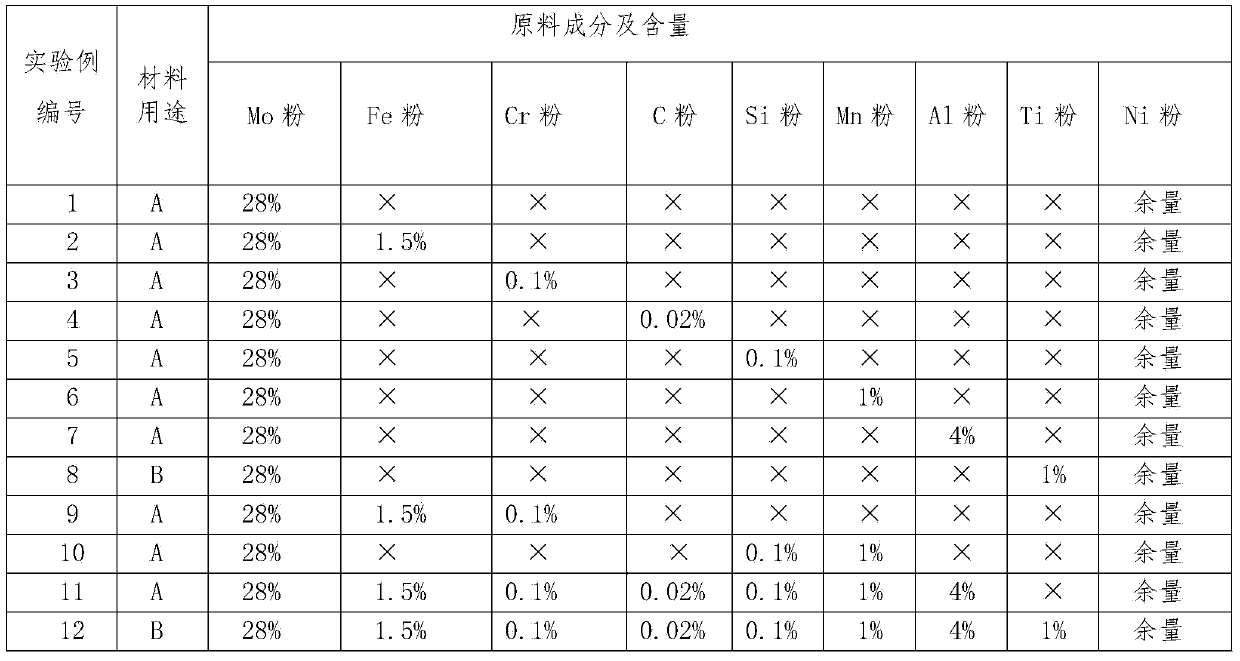

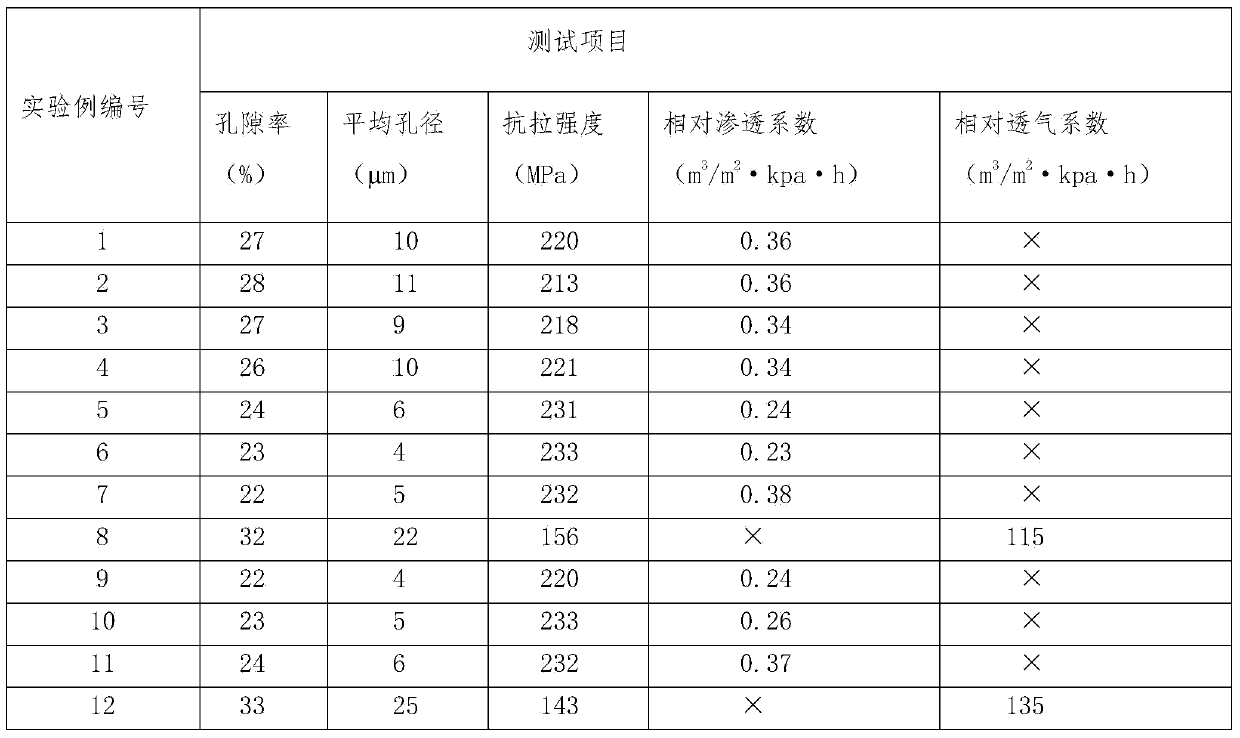

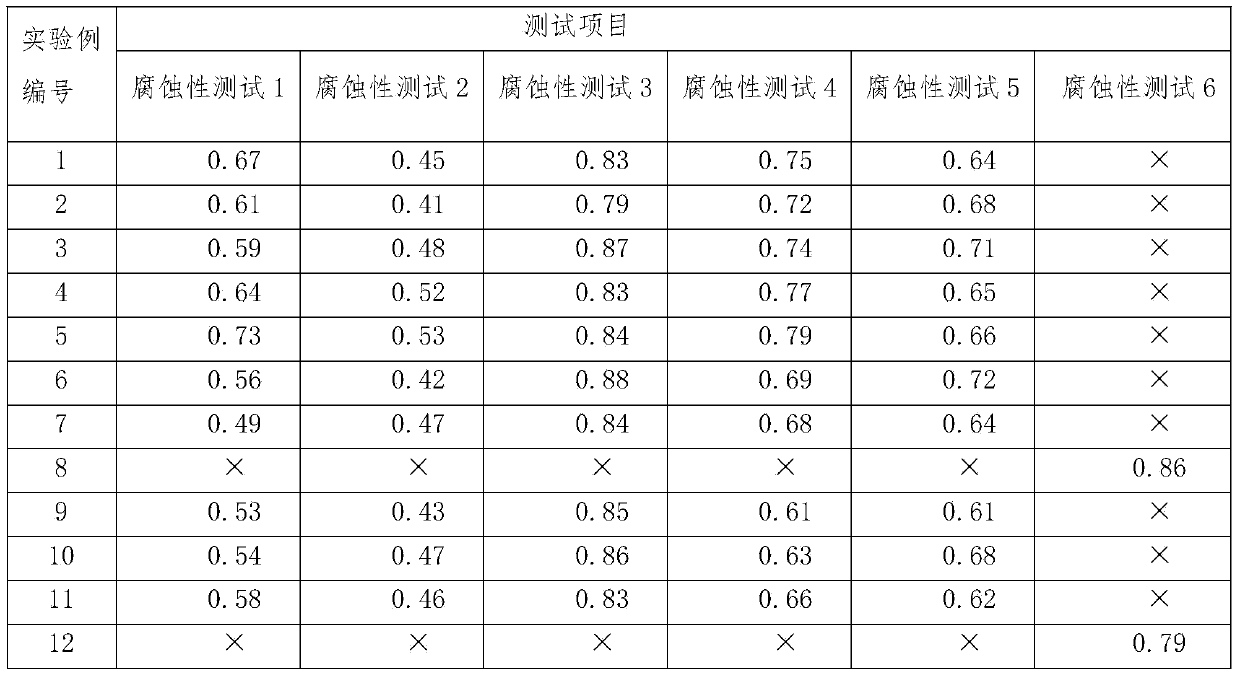

[0033] The preparation methods of the above-mentioned powder sintered Ni-based porous filter alloys of the present invention and the powder sintered Ni-based porous filter alloys obtained by these methods are specifically described below through four sets of experimental examples. Through these descriptions, those skilled in the art can clearly understand the outstanding features of the powder sintered Ni-based porous filter alloy of the present invention. The numbers of the experimental examples mentioned below are the same as the numbers corresponding to the "sample".

[0034]

[0035] See Table 1 for the raw material components and contents (in mass percent) of Experimental Examples 1 to 12 of the first group of experimental examples. Among them, the material use A refers to the prepared powder sintered porous filter alloy for liquid filtration; the material use B refers to the prepared powder sintered porous filter alloy used for gas filtration. In the experimental exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com