Full-automatic floating type hot-press forming press

A hot pressing forming and floating technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of inconvenient heating of billets, unqualified pressing, easy damage of molds, etc., to ensure processing efficiency and low scrap rate , Improving the degree of automation and the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

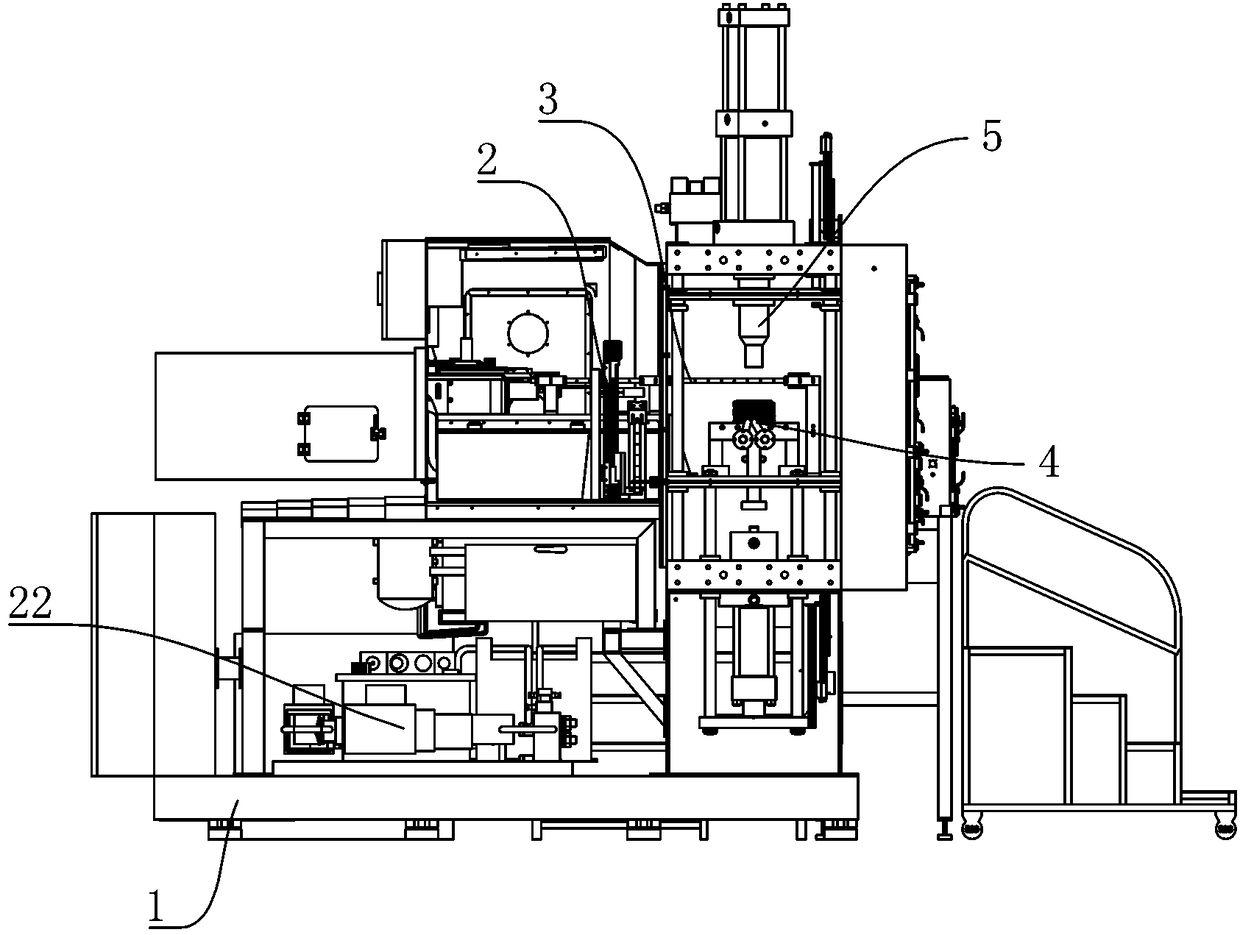

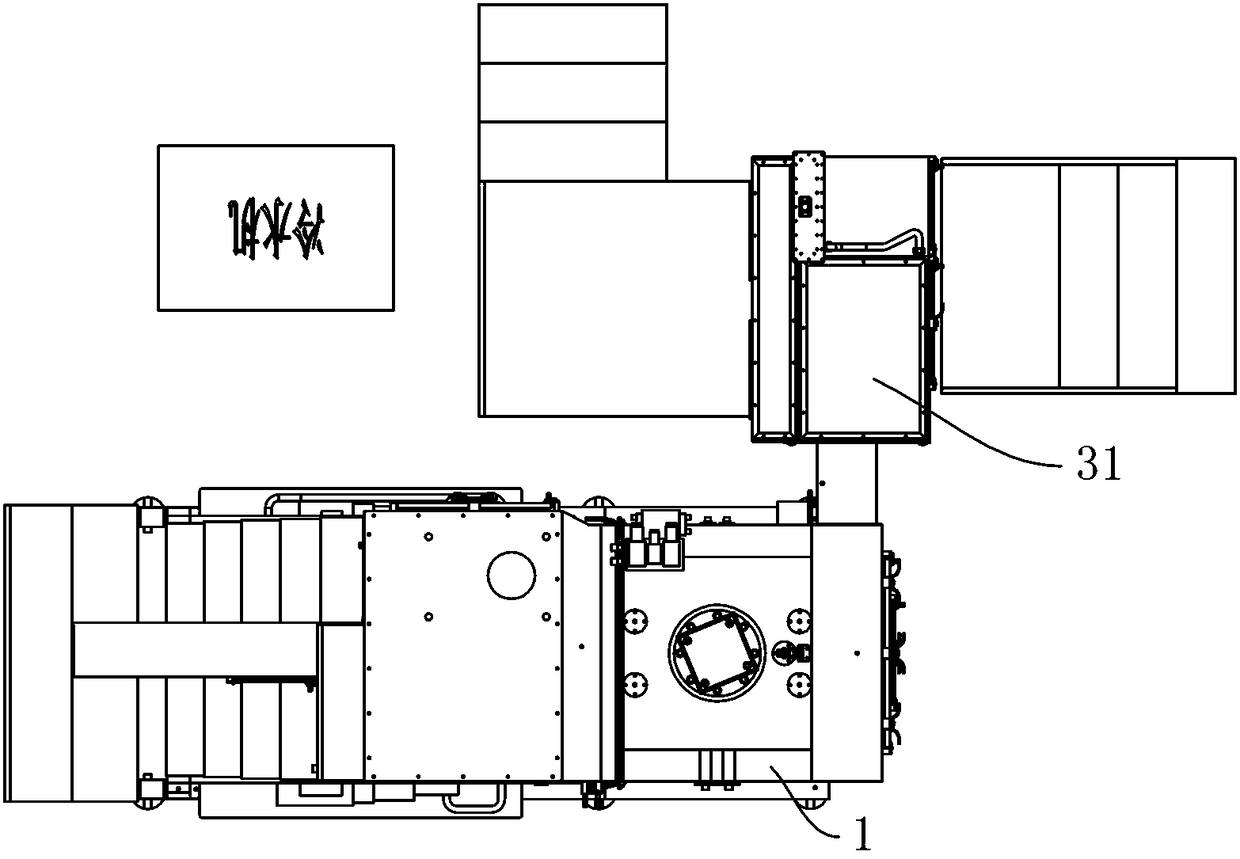

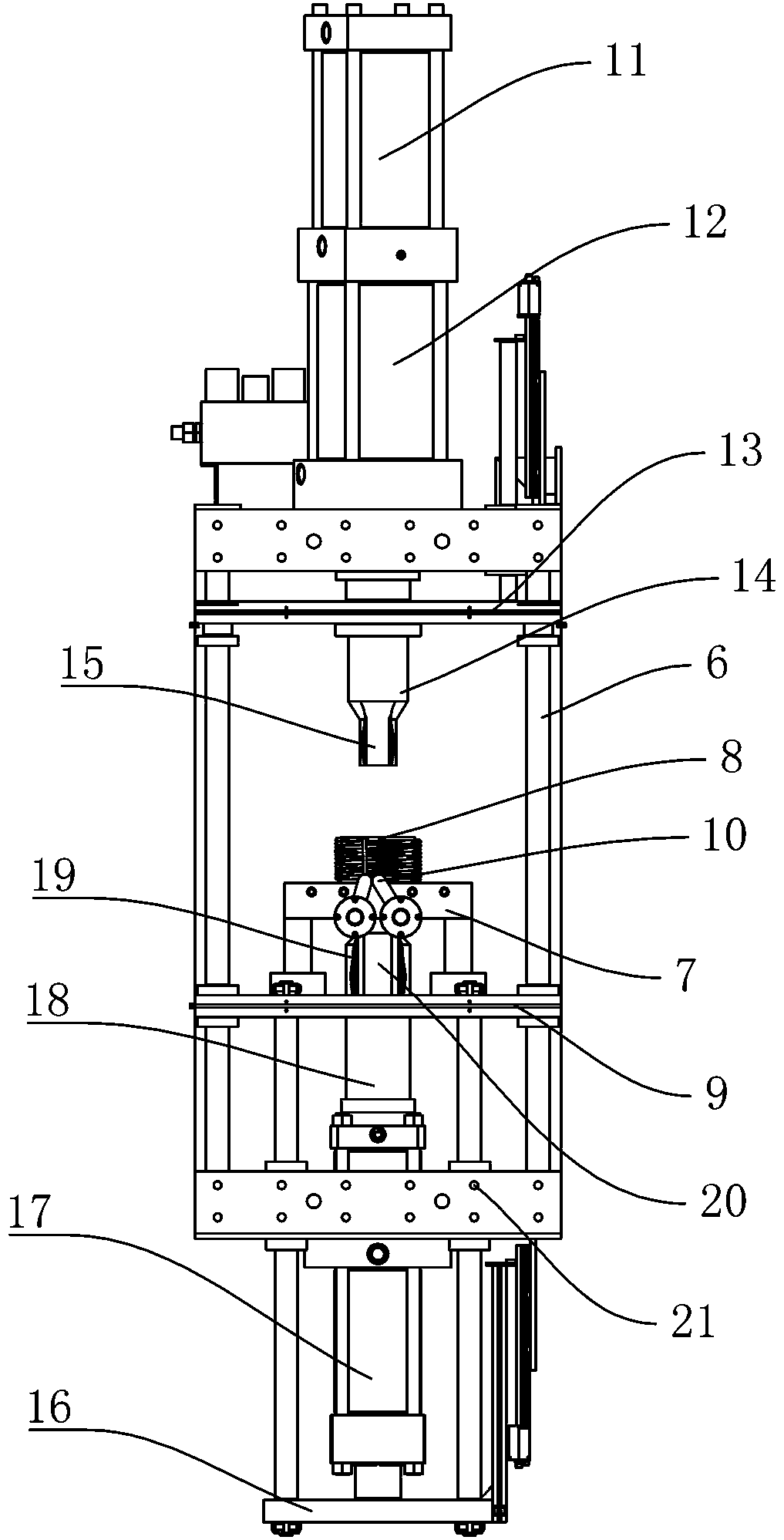

[0026] Examples, see Figure 1 to Figure 6 Shown: a fully automatic floating hot press forming press, including a sealed shield, a frame 1 is arranged inside the sealed shield, and a feeding device 2, a feeding device 3, a heating device 4, and a forming device are installed on the frame 1. The device 5, the feeding device 2, the feeding device 3 and the heating device 4 are arranged horizontally in sequence, and the forming device 5 is arranged at the upper and lower ends of the heating device 4. Plate 9, the middle guide plate 9 is slidably installed on the guide column 6, the mold base 7 is installed on the middle guide plate 9, the forming mold 8 is installed on the mold base 7, the forming mold 8 is surrounded by a heating coil 10, and the forming device 5 Including an upper punch and a lower punch, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com