Dried beancurd hydraulic machine

A technology of hydraulic press and dried tofu, which is applied in the field of hydraulic presses, can solve the problems of inconvenient placement and removal of dried tofu molds, failure to meet the needs of users, and lower quality of dried tofu, and achieve good pressing effect, convenient placement and removal, and stress resistance uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

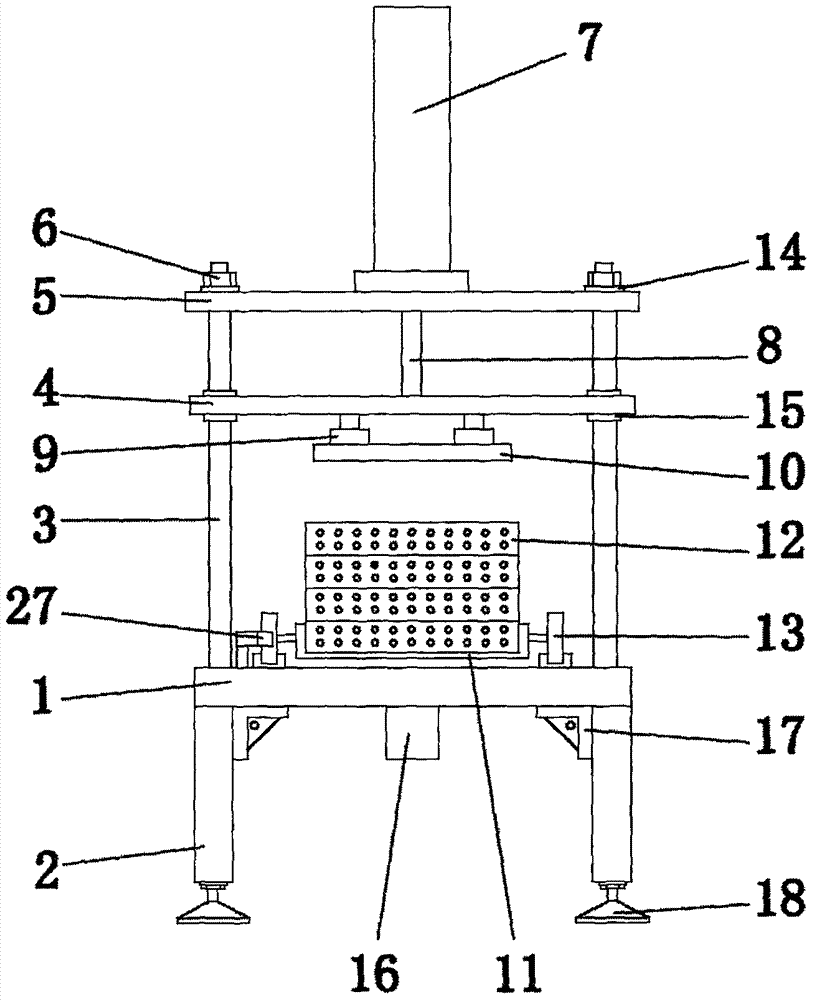

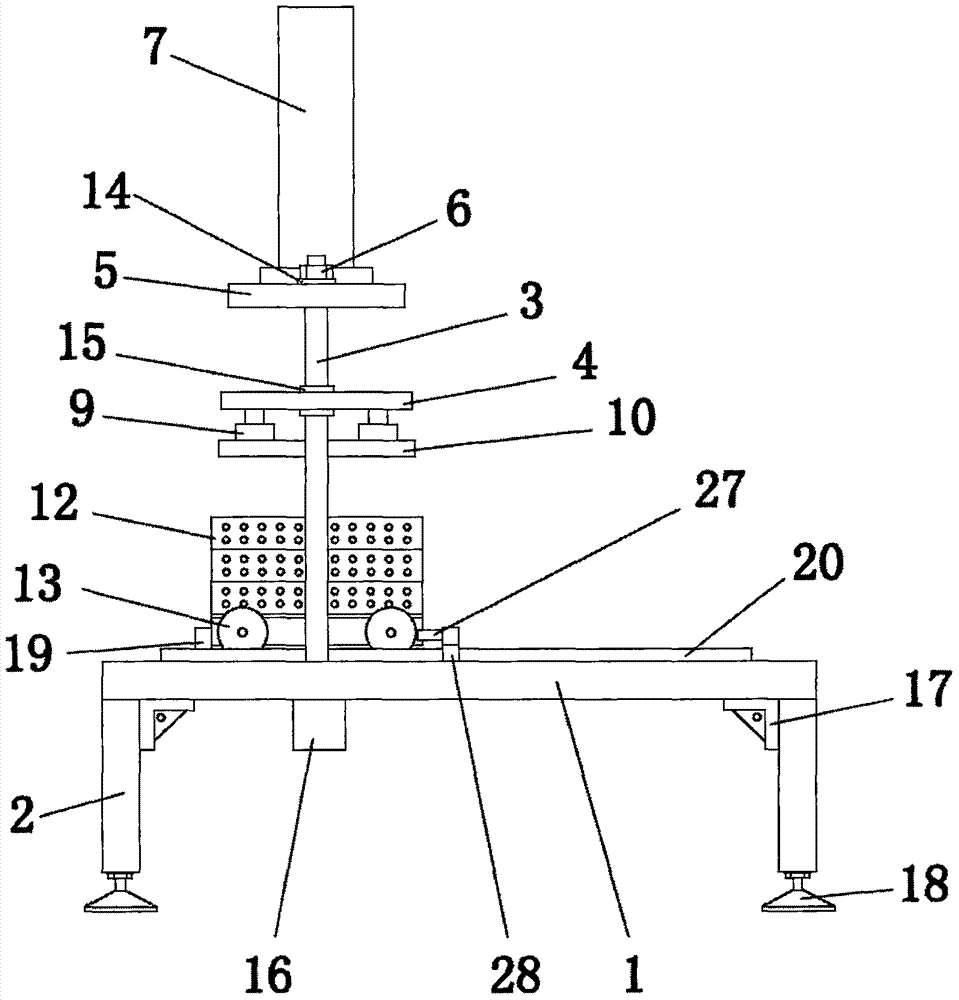

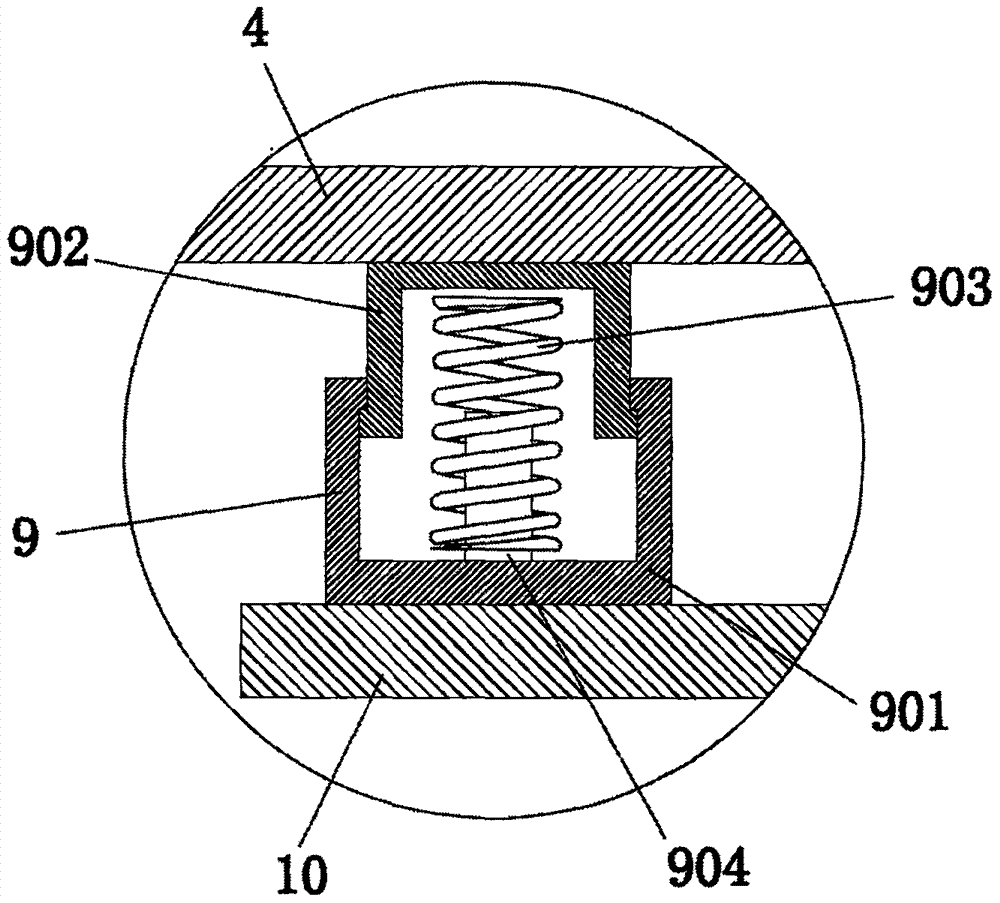

[0020] Example 1: Please refer to Figure 1-5 , the present invention provides a technical solution: a dried tofu hydraulic press, including a platform 1, legs 2 are installed at the four corners of the bottom of the platform 1, and reinforcement corners 17 are installed on the inner side of the connection between the top of the legs 2 and the platform 1, and the reinforced Angle 17 makes the support of supporting leg 2 more stable, and the bottom end of supporting leg 2 is provided with threaded hole 21, and the inside of threaded hole 21 is installed with bolt 22, and bolt 22 is threadedly connected with threaded hole 21, and the bottom end of bolt 22 is equipped with suction cup 18. The suction cup 18 can suck the ground. The outer wall of the bolt 22 is equipped with a nut 23. Tighten the nut 23 to lock the bolt 22 to prevent the bolt 22 from loosening. A flat pad 24 is installed between the nut 23 and the leg 2. The bolt 22 can adjust the height of the legs 2, and the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com