Mechanized tea brick production system

A production system and technology of tea bricks, applied in the direction of tea treatment before extraction, etc., can solve problems such as unhygienic and backward production methods, achieve high production efficiency, solve diversification, and reduce use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

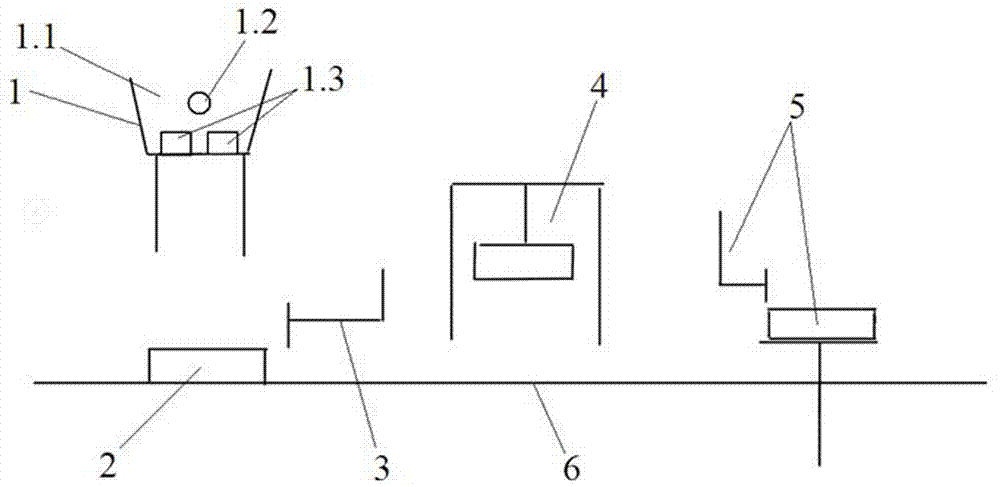

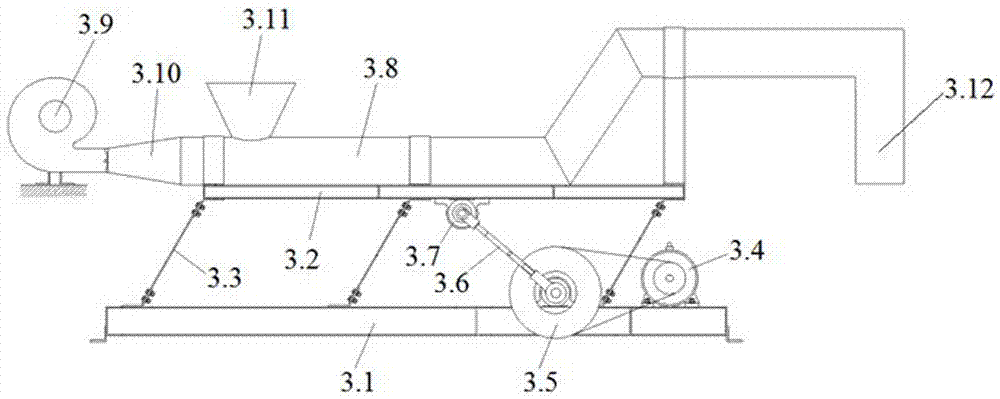

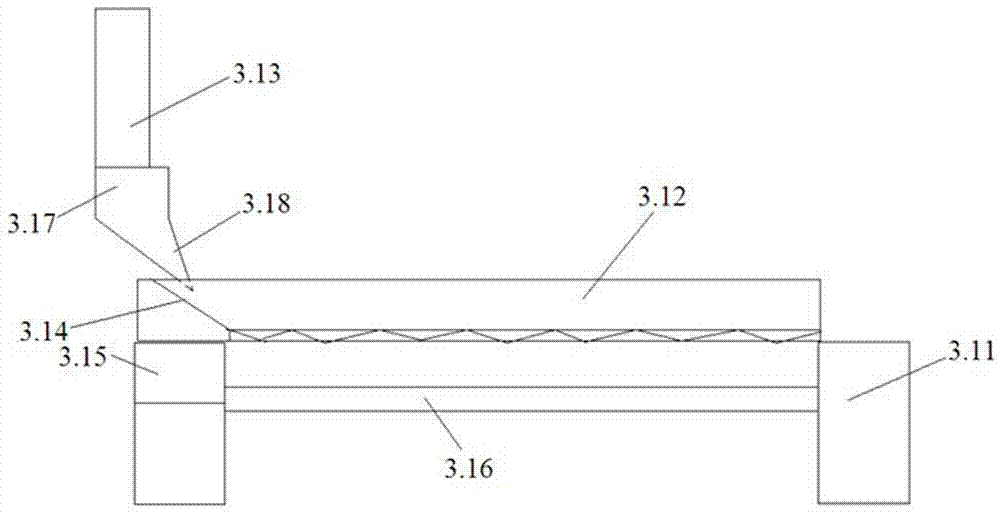

[0026] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 shown.

[0027] A set of mechanized tea brick production system, the system includes tea raw material feeding device 1, compact tea mold 2, tea conveying dust removal and smoothing device 3, hydraulic tea pressing device 4, tea brick push-off device 5 and circulating conveyor belt 6; The raw material feeding device 1, the pressed tea mold 2, and the tea conveying dust removal and smoothing device 3 are arranged on the front section of the circulating conveyor belt 6, the tea raw material feeding device 1 is arranged on the upper part of the pressed tea mold 2, and the pressed tea mold 2 Set on the circulating conveyor belt 6, the tea conveying dust removal and smoothing device 3 is set on the side of the pressed tea mold 2, the hydraulic tea pressing device 4 is set on the middle section of the circulating conveyor belt 6, and the tea brick push-off device 5 is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com