Forming device of full-automatic radiation ring floating type magnetic field forming press

A molding device and a technology for magnetic field molding, applied in the field of metallurgical powder molding presses, can solve the problems of easy generation of defects or scraps, uneven density distribution of NdFeB powder, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

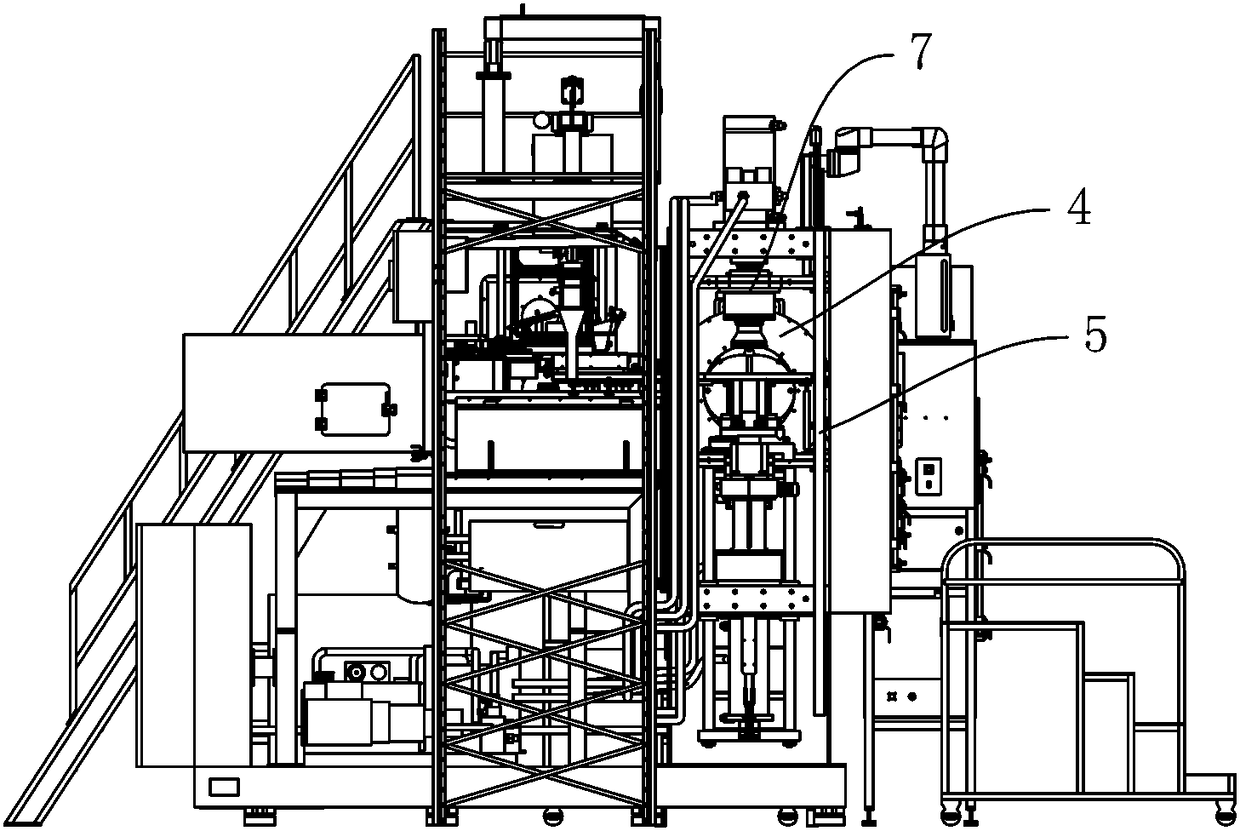

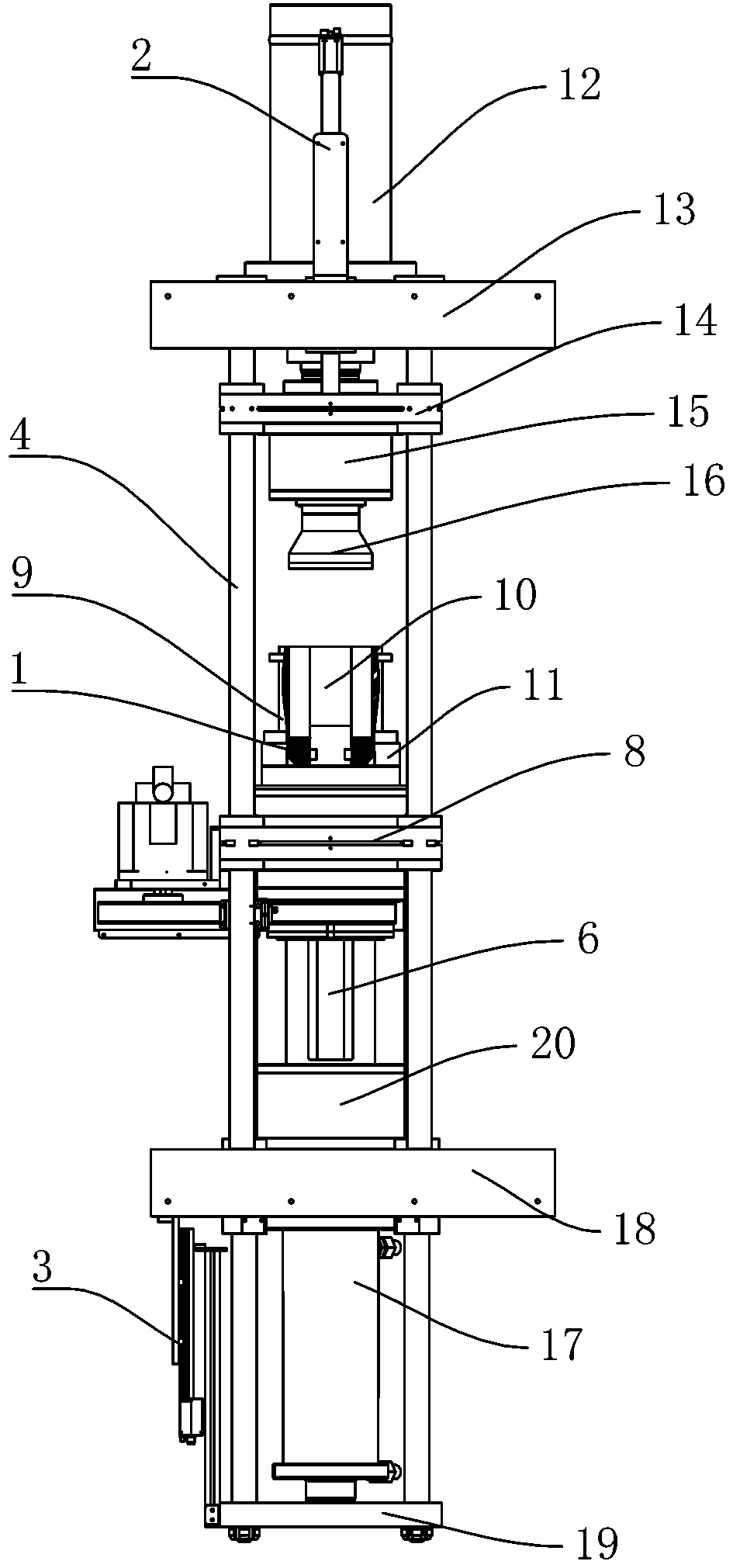

[0020] Examples, see Figure 1 to Figure 2 Shown: a forming device of a fully automatic radiation ring floating magnetic field forming press, including a forming device 7, which includes a guide post 4, a middle guide plate 8, a forming die 9, a mold frame 11, an upper punch, and a lower punch And the magnetic field coil 4, the middle guide plate 8 is installed on the guide post 4, the mold frame 11 is rotated and installed on the middle guide plate 8, the forming mold 9 is installed on the mold frame 11, and the forming mold 9 is provided with a mandrel 10, and the core Rod 10 is installed on the formwork 11, upper punch and lower punch are respectively positioned at the upper and lower ends of forming die 9, magnetic field coil 4 is positioned at the side of forming die 9, and the upper end surface of forming d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com