Paper embossing machine

An embossing machine and paper technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of easily damaged paper fibers, unsuitable for practical use, and reduced paper quality, and achieve the effects of promoting application, good pressing effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

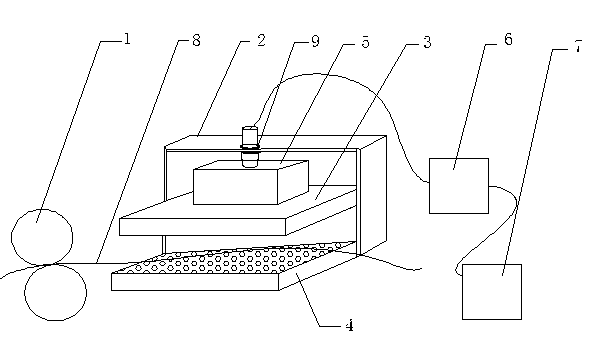

[0014] Such as figure 1 As shown, a kind of paper embossing machine of the present invention comprises flattening device 1, support 2, pressing plate 3, tread plate 4, hydraulic rod 9, fixing part 5 and hydraulic pump 6 and control cabinet 7; Described support 2 section is "Mouth" shape; the leveling device 1 is composed of double shafts; the pressure plate 3 is movably connected to the left and right sides of the support 2; the tread plate 4 is fixedly installed on the bottom of the support 2; It is fixed above the pressure plate 3, and the other end is fixed on the top of the bracket 2 through a nut; the hydraulic rod 9 is connected to the hydraulic pump 6; the hydraulic pump 6 is connected to the control cabinet 7.

[0015] Wherein, the smoothing device 1 is connected between the press plate 3 and the tread plate 4 through the paper 8; a pipeline is arranged between the hydraulic rod 9 and the hydraulic pump 6.

[0016] The paper embossing machine of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com