Fibre decomposite and fibre de-composition apparatus

A fiberizing machine and fiberizing technology, applied in the direction of raw material separation, etc., can solve the problems of large vibration noise, large dust, unfavorable molding, etc., and achieve the effect of reducing power consumption, reducing vibration noise, and improving crushing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

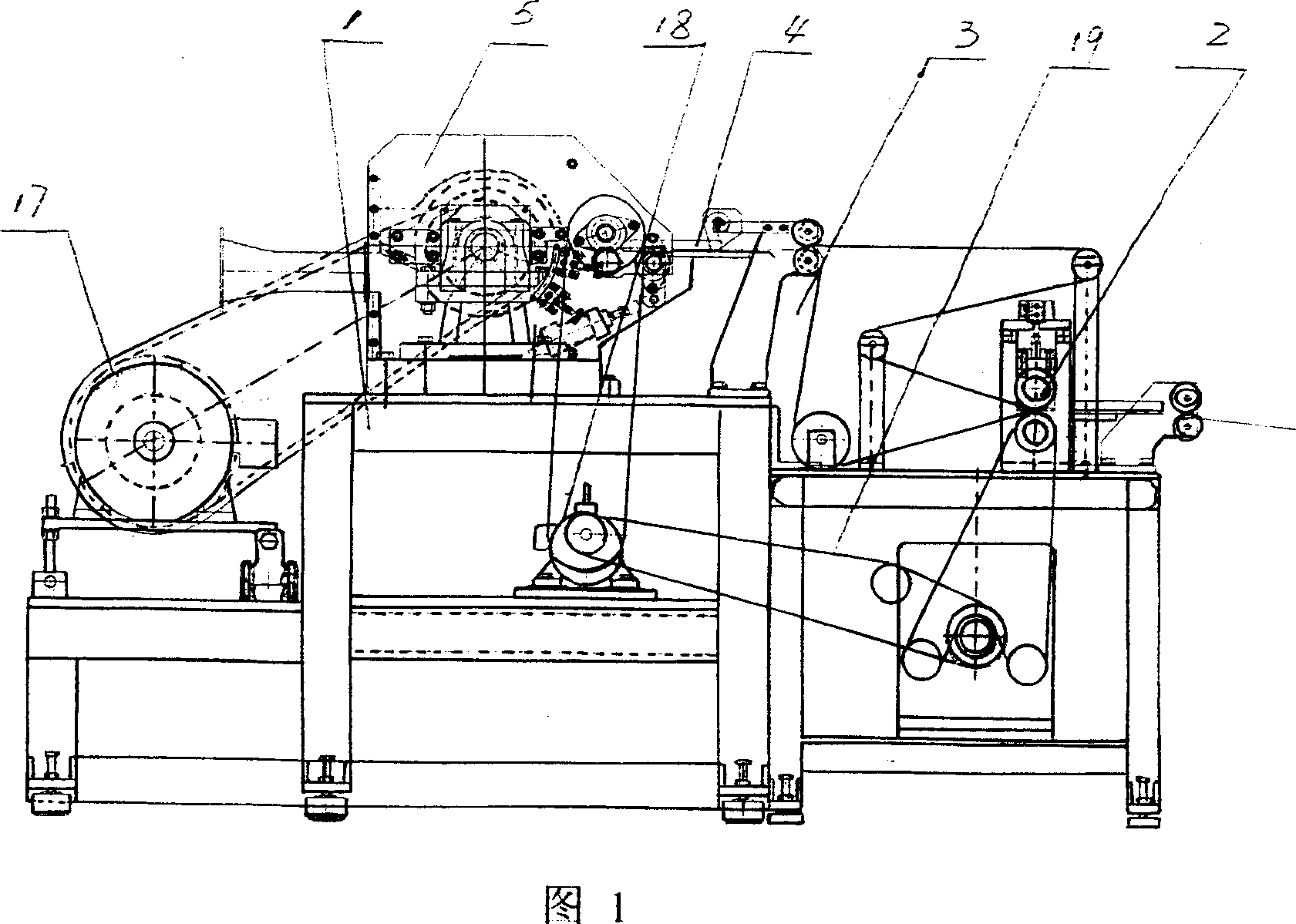

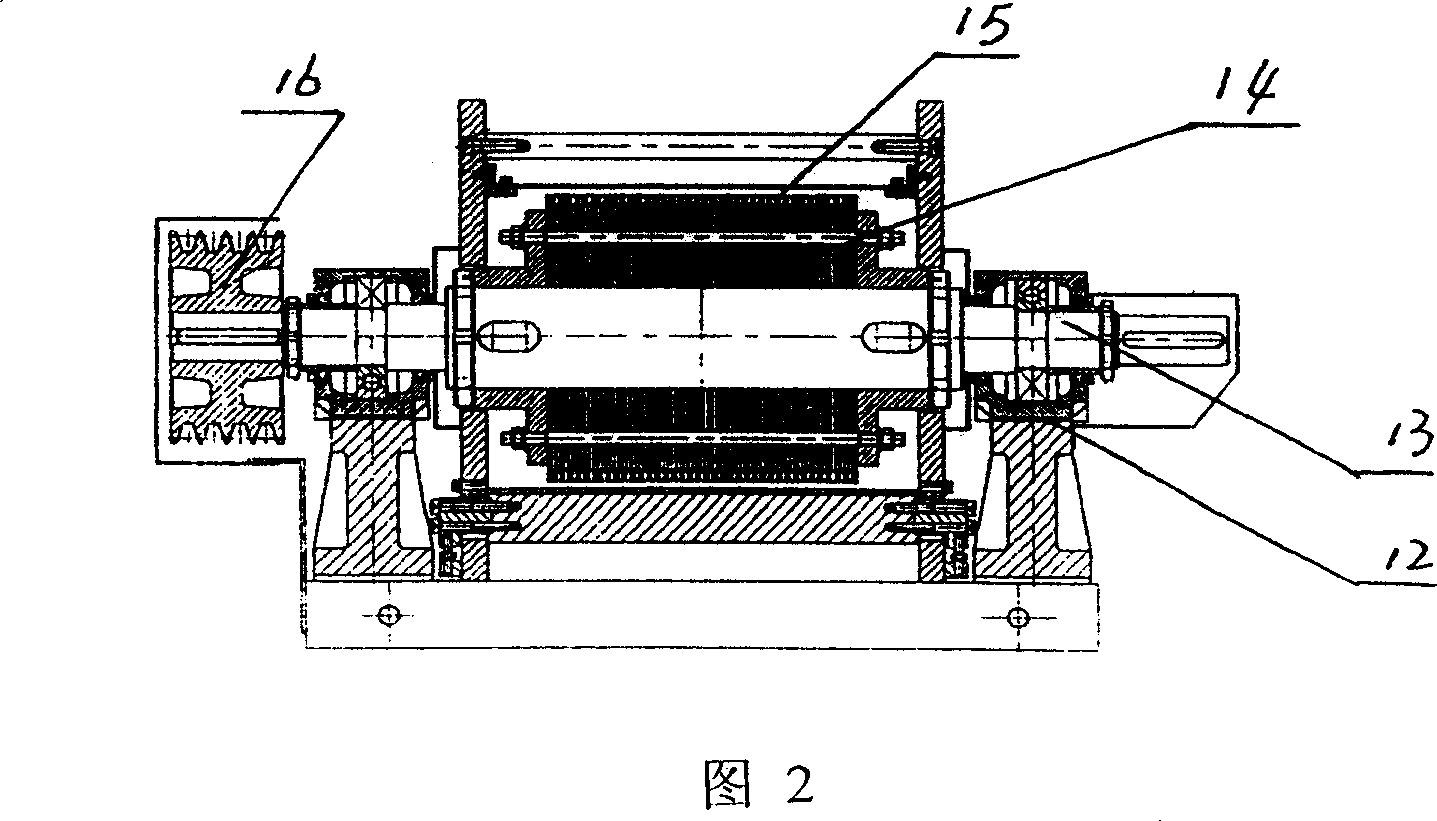

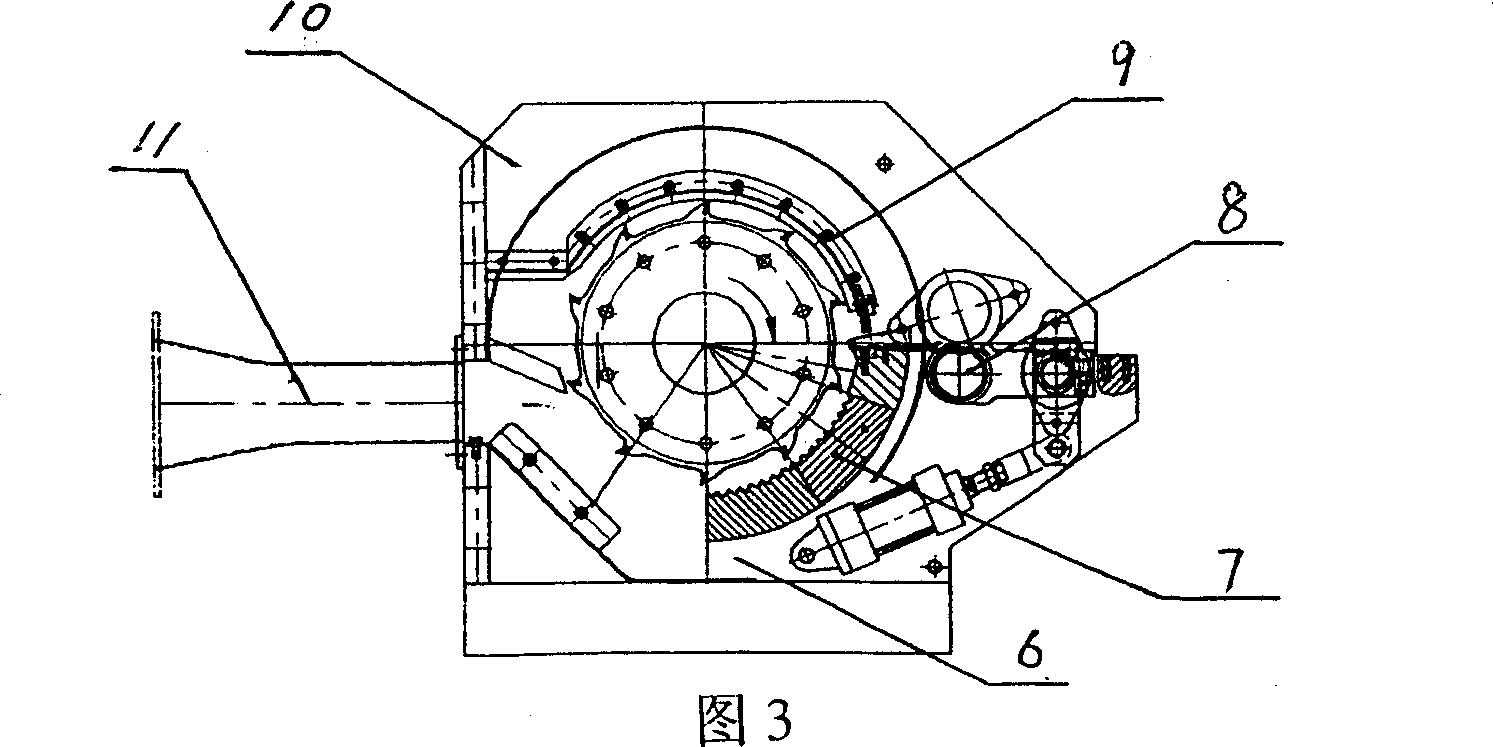

[0018] Embodiment 1: with reference to accompanying drawing 1~3 and Fig. 8 and Fig. 9. For the defibrated body, the discharge port 11 communicates with the pulverized body, and the pulverized system is in the prior art, so it will not be described here. The cutter head 14 is located in the cutter box plate 10 through the main shaft 13, the main shaft 13 is supported by the bearing housing 12, the belt pulley 16 is located at one end of the main shaft 13, and the fixed tooth block 7 is located at the lower part of the cutter head 14 between the cutter box plates and is in clearance fit with the cutter head. The feeding assembly 8 is located between the arc-shaped sealing plate 9 and the fixed tooth block 7, and the discharge port is directly facing the cutter head 14. The bottom of the plurality of cutter heads 15 of the blade 54 is a concave arc-shaped groove 54. The cutter head 14 is composed of multiple The blades 54 are flat stacked and the cutter heads 15 of the multi-blad...

Embodiment 2

[0019] Embodiment 2: with reference to accompanying drawing 1~8. A defibrating machine composed of a defibrating body, which includes a frame 1, a defibrating body 5, a main shaft drive motor 17, a conveying mechanism driving motor 18 and a conveying mechanism 19, the defibrating body 5 is located on the frame 1, and the pulp plate folding mechanism 3 is located in front of the double-layer feeding port of the defibrating body 5 and is located on the frame 1, the cutting knife assembly 2 is located in front of the pulp plate folding mechanism 3 and is located on the frame 1, and the cutting knife assembly 2 is transported by the conveying mechanism The drive motor 18 and the transmission mechanism drive the cutting knife assembly 2 to cut the knife and transport the cut sheet to the pulp sheet folding mechanism 3 through the conveying mechanism 19, and then fold it into double layers through the pulp sheet folding mechanism and then pass through the defibrating body 5 The feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com