Method for improving performance of thermal compression or thermal deformation radiation orientation neodymium iron boron permanent magnet ring and axial uniformity thereof

A radiation orientation, permanent magnet ring technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve problems such as grain growth, reduce loss, improve performance and uniformity, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

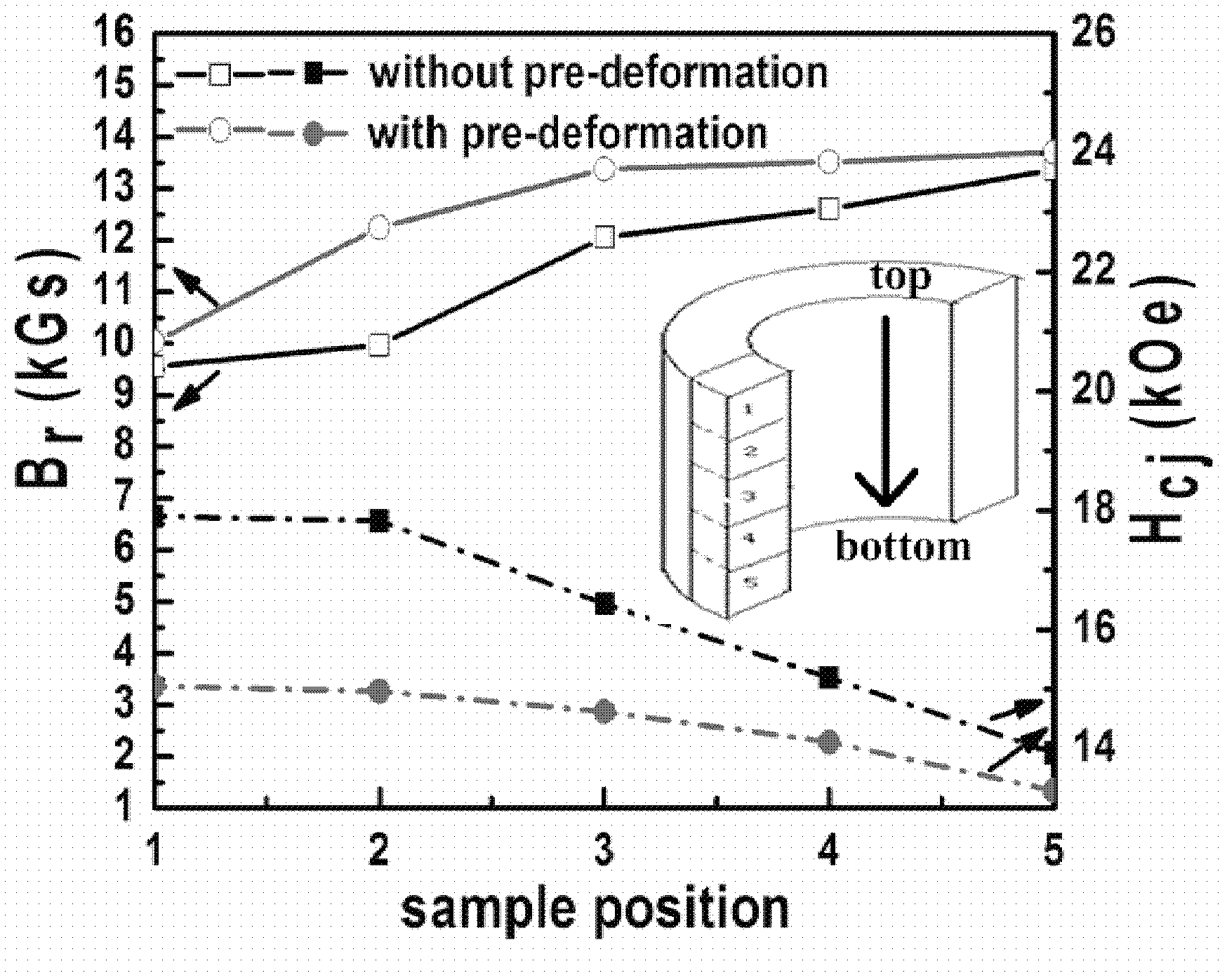

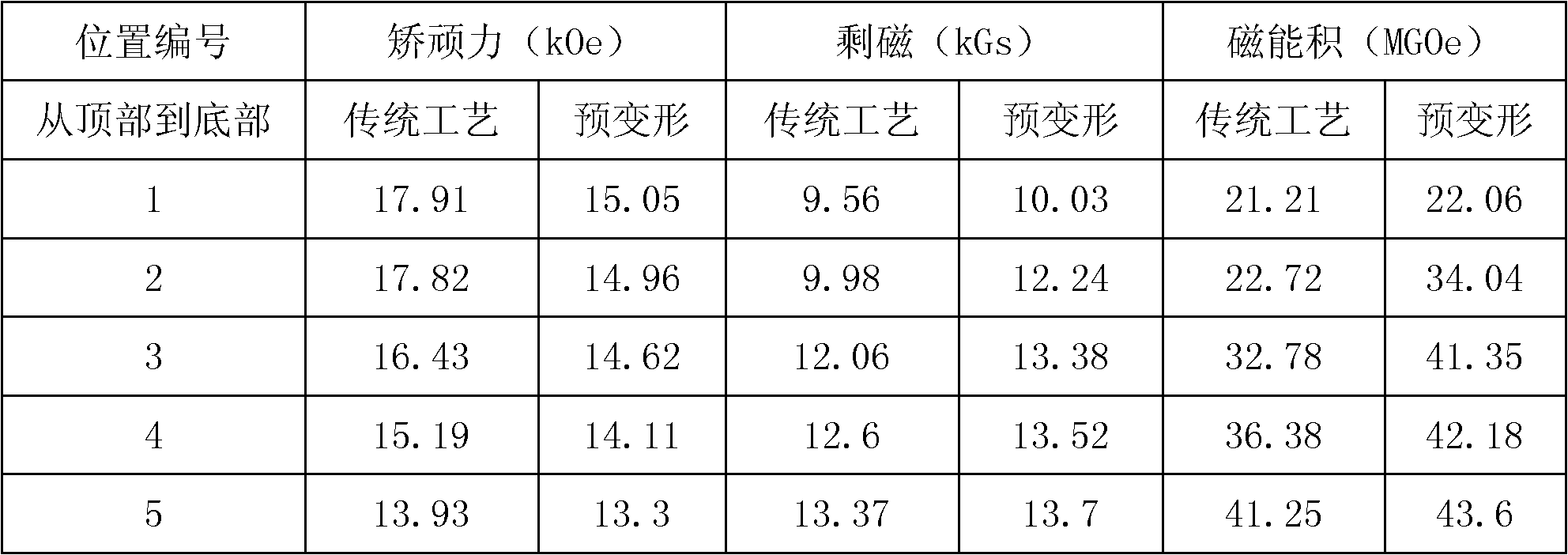

Embodiment 1

[0021] 17g of commercial MQU-F quick-quenching magnetic powder is put into a hot pressing mold with an inner diameter of 13mm.

[0022] Put the heat press mold into the vacuum induction heat press and evacuate to 6×10 -2 Below Pa.

[0023] Wait until the vacuum reaches 6×10 -2 At Pa, turn on the induction heating system, and turn on the hydraulic system at the same time, adjust the pressure acting on the mold to 200MPa, and raise the temperature from room temperature to 670°C at a constant speed for 5 minutes, and keep the pressure at 670°C for 1 minute.

[0024] After the heat preservation and pressure holding are completed, quickly turn off the heating system and hydraulic system, adjust the pressure to the minimum, and cool down to room temperature within 30 minutes, take out the mold and demould it.

[0025] Put the hot-pressed magnet prepared above into a mold with an inner diameter of 19.5mm and put the mold into a vacuum induction hot press, and vacuumize it to 6×10 ...

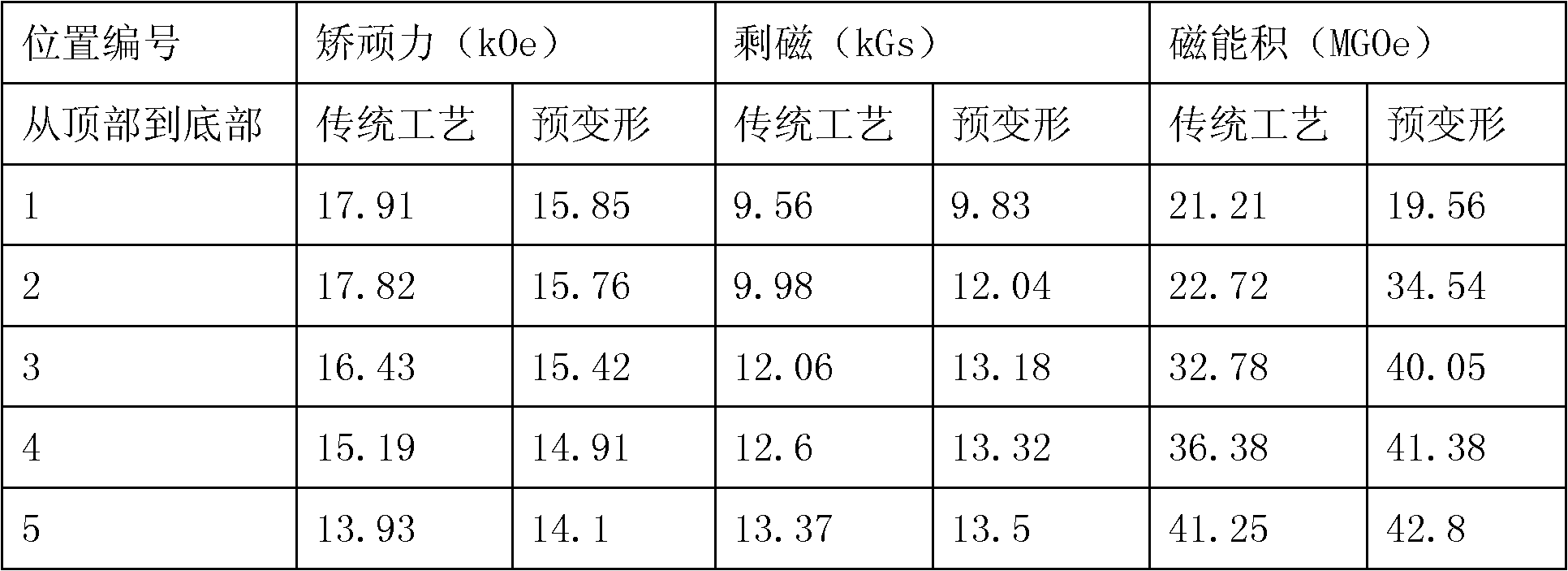

Embodiment 2

[0038] Put 27g of commercial MQU-F quick-quenching magnetic powder into a hot pressing mold with an inner diameter of 19mm.

[0039] Put the heat press mold into the vacuum induction heat press and evacuate to 6×10 -2 Below Pa.

[0040] Wait until the vacuum reaches 6×10 -2 At Pa, turn on the induction heating system, and turn on the hydraulic system at the same time, adjust the pressure acting on the mold to 200MPa, and raise the temperature from room temperature to 670°C at a constant speed for 5 minutes, and keep the pressure at 670°C for 1 minute.

[0041] After the heat preservation and pressure holding are completed, quickly turn off the heating system and hydraulic system, adjust the pressure to the minimum, and cool down to room temperature within 30 minutes, take out the mold and demould it.

[0042] Cut the hot-pressed magnets prepared above into 15.5mm hot-pressed magnets, put them into a mold with an inner diameter of 19.5mm, put the mold into a vacuum induction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com