Fiber aerogel foam concrete, preparation method and application thereof

A foamed concrete and aerogel technology, which is used in the field of thermal insulation materials and lightweight, can solve the problems of poor slurry fluidity, difficult to achieve self-weight of foamed concrete, complicated preparation process, etc., achieve good thermal insulation performance, reduce bonding The degree is not high, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

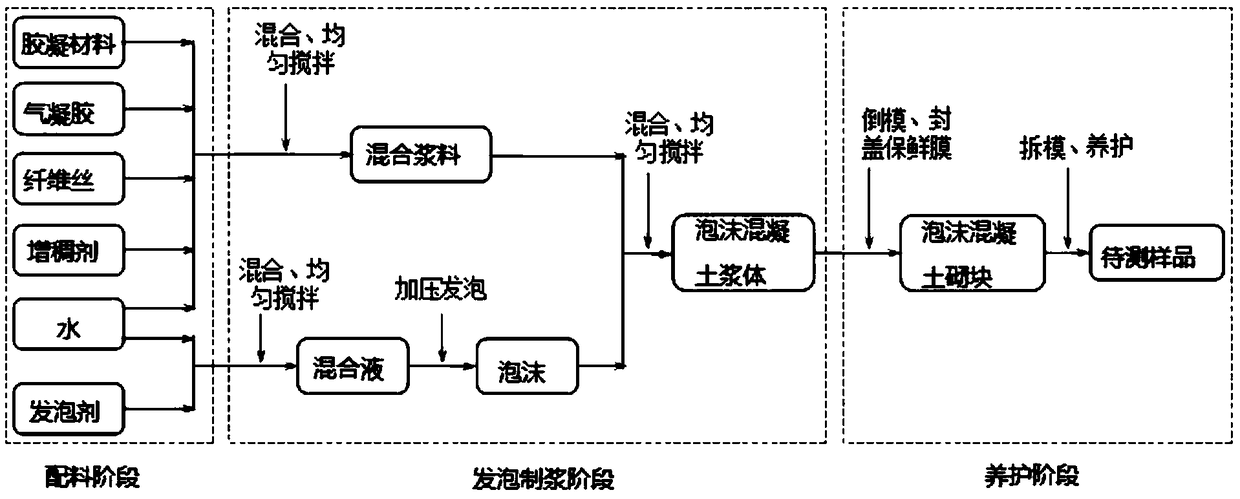

Method used

Image

Examples

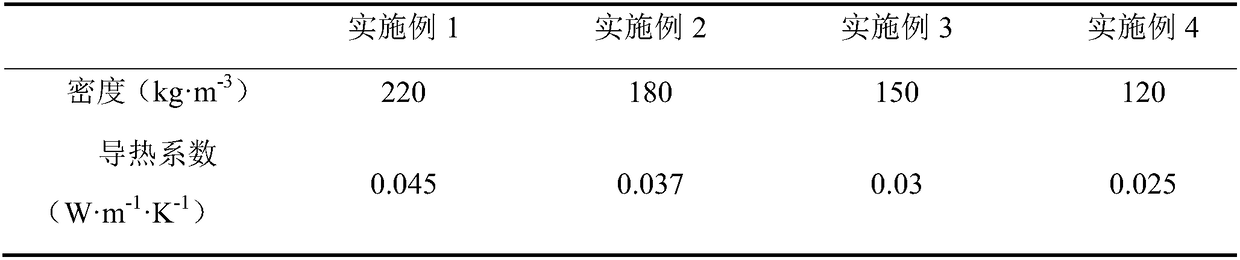

Embodiment 1

[0039] The fiber airgel foam concrete prepared in this embodiment is filled with clay airgel powder, wherein the clay airgel powder has a particle size of 60 mesh (about 250 μm), a porosity of 85% and a porosity of 30nm in diameter.

[0040] The fiber filaments in this embodiment are glass fiber filaments with a diameter of 40 μm in a dispersed state.

[0041] A kind of preparation method of glass fiber airgel foam concrete, concrete steps are as follows:

[0042] (1) Mix water and diatomaceous earth according to the mass ratio of 1000:1, and stir evenly to obtain thickened water;

[0043] (2) Dry mix the silicate PO42.5 cement and the clay airgel powder, then add the thickening water obtained in step (1), and stir evenly to obtain the clay airgel concrete slurry; wherein the compound silicic acid The mass ratio between salt PO42.5 cement, clay airgel powder and thickening water is 1:0.15:0.7;

[0044] (3) Slowly add the dispersed glass fiber filaments to the clay airgel co...

Embodiment 2

[0048] The fiber airgel foam concrete prepared in this embodiment is based on the carbon airgel powder as the filling material, wherein the carbon airgel powder has a particle diameter of 70 mesh (about 212 μm), a porosity of 90% and a porosity The diameter is 35nm.

[0049] The fibers used in this embodiment are quartz fibers with a diameter of 35 μm in a dispersed state.

[0050] A preparation method of quartz fiber airgel foam concrete, the specific steps are as follows:

[0051] (1) Mix water and barstone soil in a mass ratio of 1000:2, and stir evenly to obtain thickened water;

[0052] (2) Carry out dry mixing with magnesium oxychloride PO42.5 cement and carbon airgel powder, then add the thickening water prepared in step (1), stir evenly, obtain carbon airgel concrete slurry; The mass ratio between magnesium PO 42.5 cement, carbon airgel powder and thickening water is 1:0.2:0.75;

[0053] (3) Slowly add the dispersed quartz fiber filaments into the carbon airgel conc...

Embodiment 3

[0057] The fiber airgel foam concrete prepared in this embodiment is based on SiO 2 Airgel powder is the filling material, among them, SiO 2 The particle size of the airgel powder is 80 mesh (about 180 μm), the porosity is 93%, and the pore diameter is 40 nm.

[0058] The fibers used in this embodiment are polystyrene fibers with a diameter of 30 μm in a dispersed state.

[0059] A preparation method of polystyrene fiber airgel foam concrete, the specific steps are as follows:

[0060] (1) Mix water and sodium bentonite in a mass ratio of 1000:3, and stir evenly to obtain thickened water;

[0061] (2) Combine sulfoaluminate PO 42.5 cement with SiO 2 The airgel powder is dry-mixed, and then the thickened water prepared in step (1) is added, and stirred evenly to obtain SiO 2 Airgel concrete paste; the sulphoaluminate PO 42.5 cement, SiO 2 The mass ratio between airgel powder and thickening water is 1:0.25:0.8;

[0062] (3) Slowly add the dispersed polystyrene fiber to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com