Method for stereolithography-based 3D printing ceramic component suitable for self repair/self enhancement

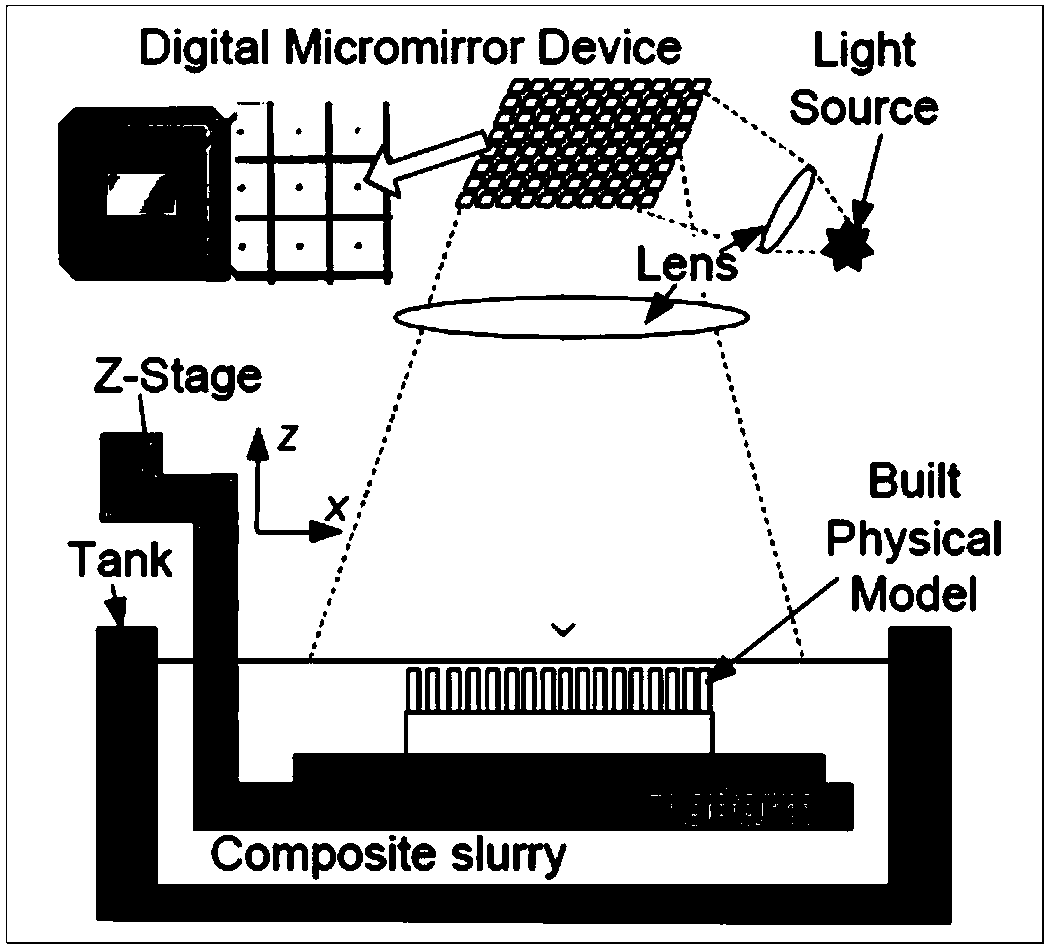

A light-curing molding and 3D printing technology, applied in the direction of additive processing, can solve the problem of low solid phase content, achieve high density, increase green body density, and repair microscopic cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] (1) Green body preparation

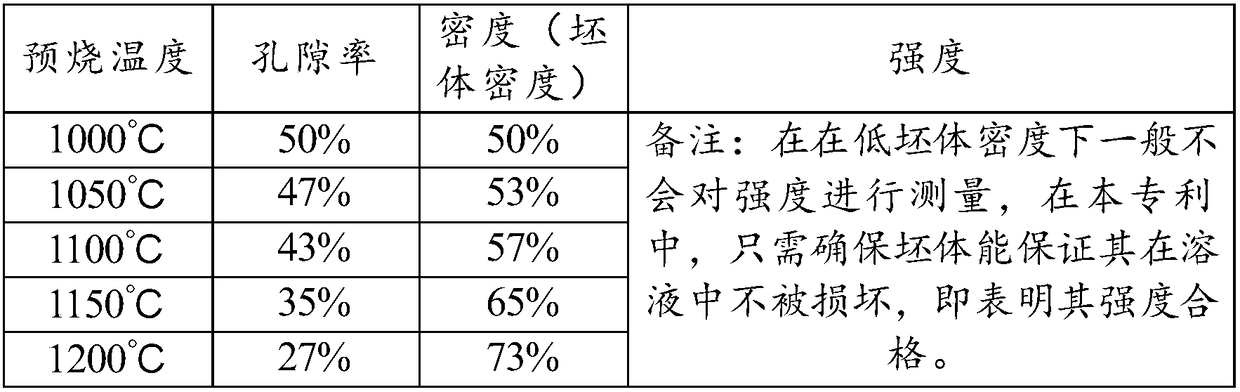

[0122] Prepare the light-curing premix solution with ethoxylated pentaerythritol tetraacrylate, methylpentanol, polydimethylsiloxane, etc. in a ratio of 100:2:2, and then mix it with alumina ceramic powder at a solid phase content of 36vol% (ie The volume ratio of the ceramic powder to the light-cured ceramic slurry) is mixed to prepare the alumina light-cured slurry. The main process parameters of photocuring were optimized, the exposure time was 6s, and the layer thickness was 10μm. Then, the photocured ceramic slurry was subjected to photocuring treatment, and the obtained alumina body was first degreased in vacuum and then degreased in air. The heating rate was uniform. The temperature is 5°C / min, the maximum temperature is 650°C, and the holding time is 2h. Then pre-burning treatment is carried out, the pre-burning temperature is 1100°C, the heating rate is 5°C / min, and the holding time is 2h. The porosity of the green body obtained a...

Embodiment 2

[0133] Example 2 Zirconia

[0134] (1) Green body preparation

[0135] Prepare the light-curing premix solution with ethoxylated pentaerythritol tetraacrylate, methylpentanol, polydimethylsiloxane, etc. in a ratio of 100:2:2, and then mix it with alumina ceramic powder at a solid phase content of 37vol% (ie The volume ratio of the ceramic powder to the light-cured ceramic slurry) is mixed to prepare the zirconia light-cured slurry. The main process parameters of photocuring were optimized, the exposure time was 6s, and the layer thickness was 10μm. Then, the photocured ceramic slurry was subjected to photocuring treatment, and the obtained alumina body was first degreased in vacuum and then degreased in air. The heating rate was uniform. The temperature is 5°C / min, the maximum temperature is 650°C, and the holding time is 2h. Then pre-burning treatment is carried out, the pre-burning temperature is 1100°C, the heating rate is 5°C / min, and the holding time is 2h. The porosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com