Preparation method of porous extremely small curved structure aluminum oxide ceramics based on 3D printing

A technology of alumina ceramics and extremely small curved surfaces is applied in the field of porous ceramics to achieve the effects of convenient operation, low cost and accurate precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

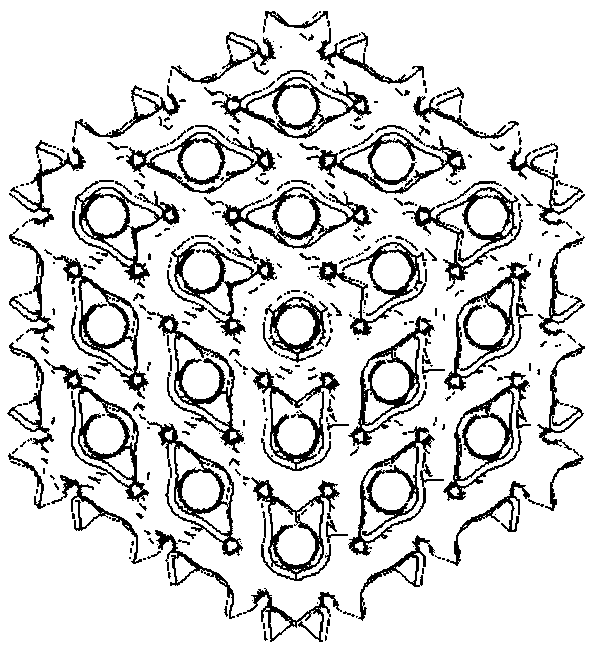

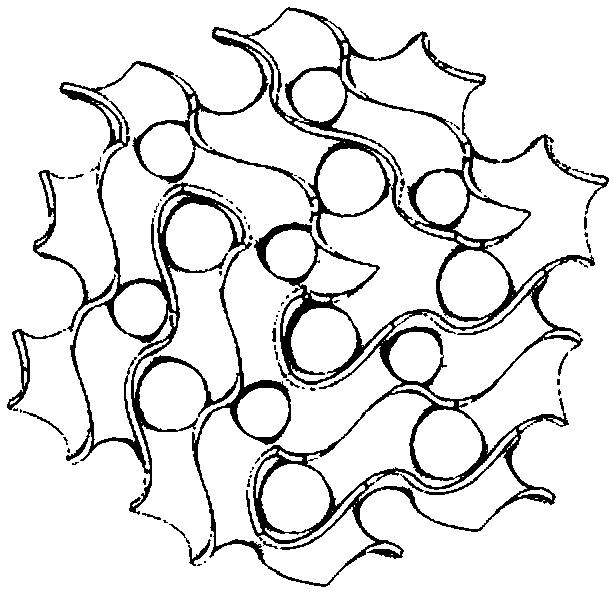

[0028] 1. Use Rhinoceros, Grasshopper and other 3D modeling software to design the required porous structure, and obtain the structure model with the best porosity. The specific process is as follows: input the minimum surface function to Gyrido, the input terminal of the Grasshopper battery pack, realize the digital modeling process through the battery pack, and finally output the minimum surface model by Mesh.

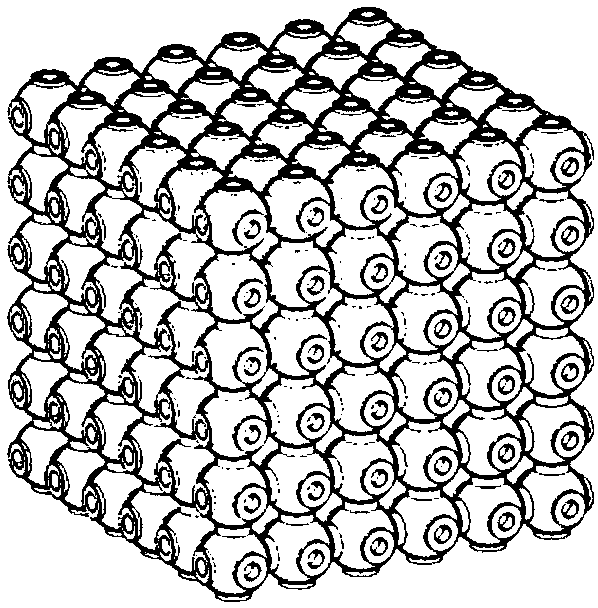

[0029] 2. Configure the special slurry required for printing, use photosensitive resin as the solvent, add appropriate amount of alumina powder, binder, photoinitiator, and photopolymerizer in sequence, mix thoroughly and then perform ball milling.

[0030] 3. Use the designed BESK printer to print. First, import the printed model data into the Q3DP software designed with the printer, adjust the parameters and slice the model, and then adjust the substrate to be parallel to the bottom resin tank and determine the best starting position , to ensure that the curing eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com