Asynchronous door knife with car door lock, elevator door operator and car door system

A technology for elevator door operators and door knives, which is applied to elevators, lifts, transportation and packaging in buildings. It can solve problems such as broken contact springs, arcing, and reduced reliability, and achieve reliable locking and low cost. The effect of low height and small door gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

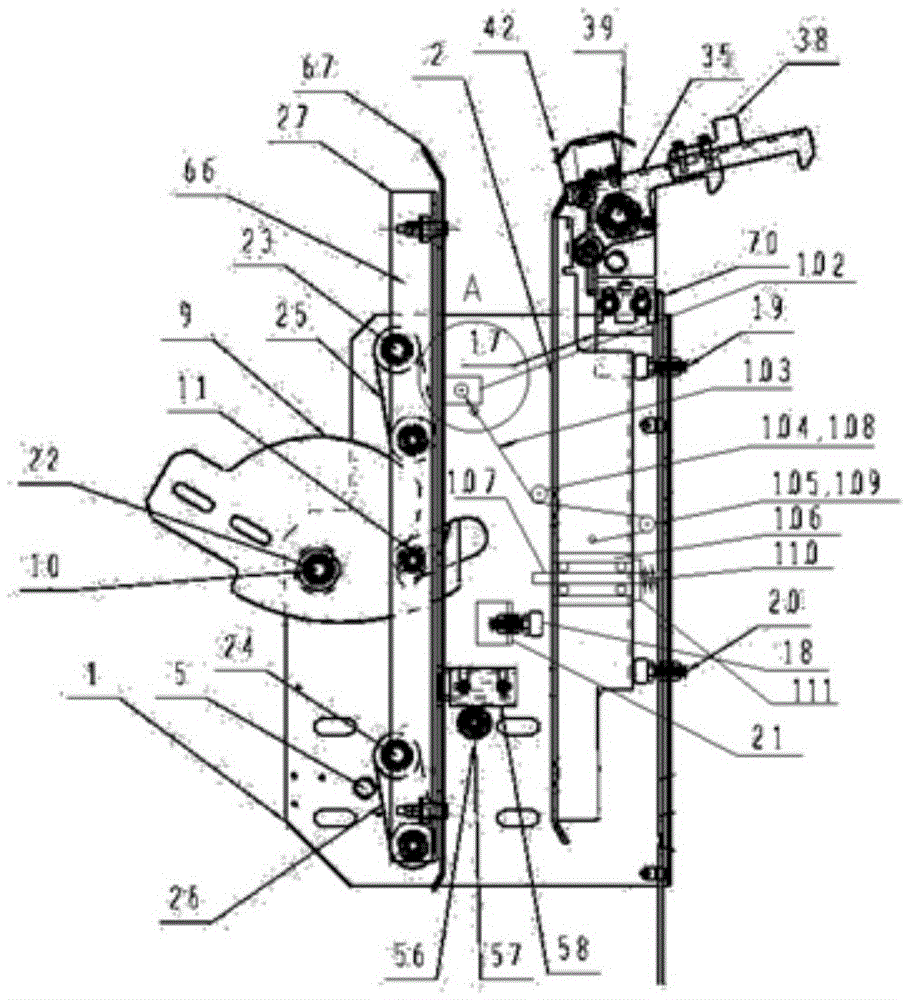

[0068] Such as figure 1 As shown, the asynchronous door knife with the car door lock of the present invention comprises a door knife mounting seat 1, a first unlocking blade 2, a second unlocking blade device 27, a rotating lock hook assembly 35, a fixed hook, and a switch hitting plate 42; The mounting seat 1 is connected to the first unlocking blade 2 through a horizontal guide mechanism, and the first clamping plate 66 and the second clamping plate 67 in the first unlocking blade 2 and the second unlocking blade device 27 are arranged parallel to each other and perpendicular to the horizontal plane;

[0069] On the door knife mounting seat 1, the shaft 10 for the cam, the limit shaft 5, the shaft 23 for the second upper swing rod, the shaft 24 for the second lower swing rod, and the shaft 57 for the guide wheel are fixedly installed on the door knife mounting seat 1; the shaft 57 for the guide wheel passes through the bearing Turn and connect guide wheel 56;

[0070] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com