Patents

Literature

41 results about "Blades (device)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

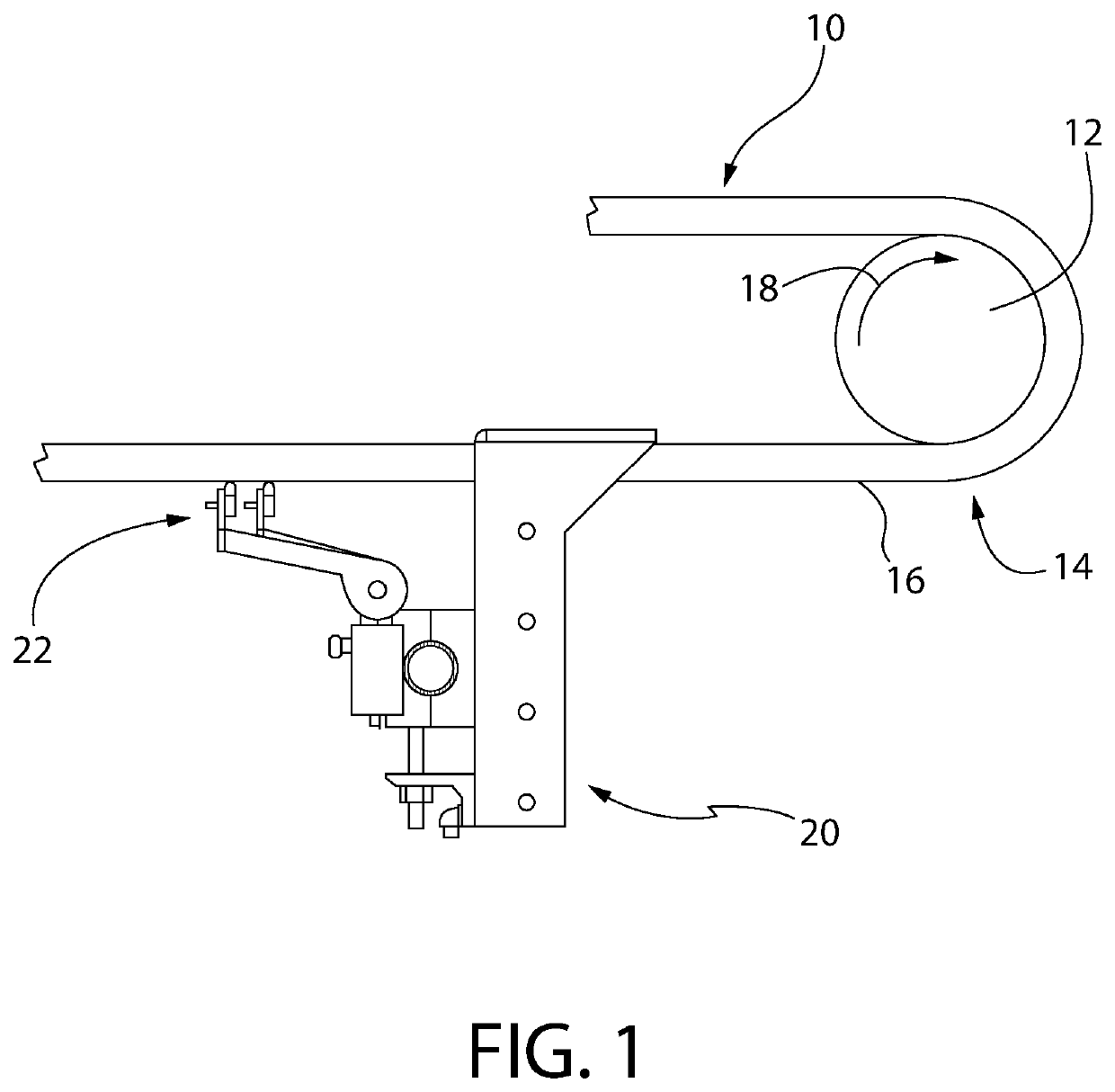

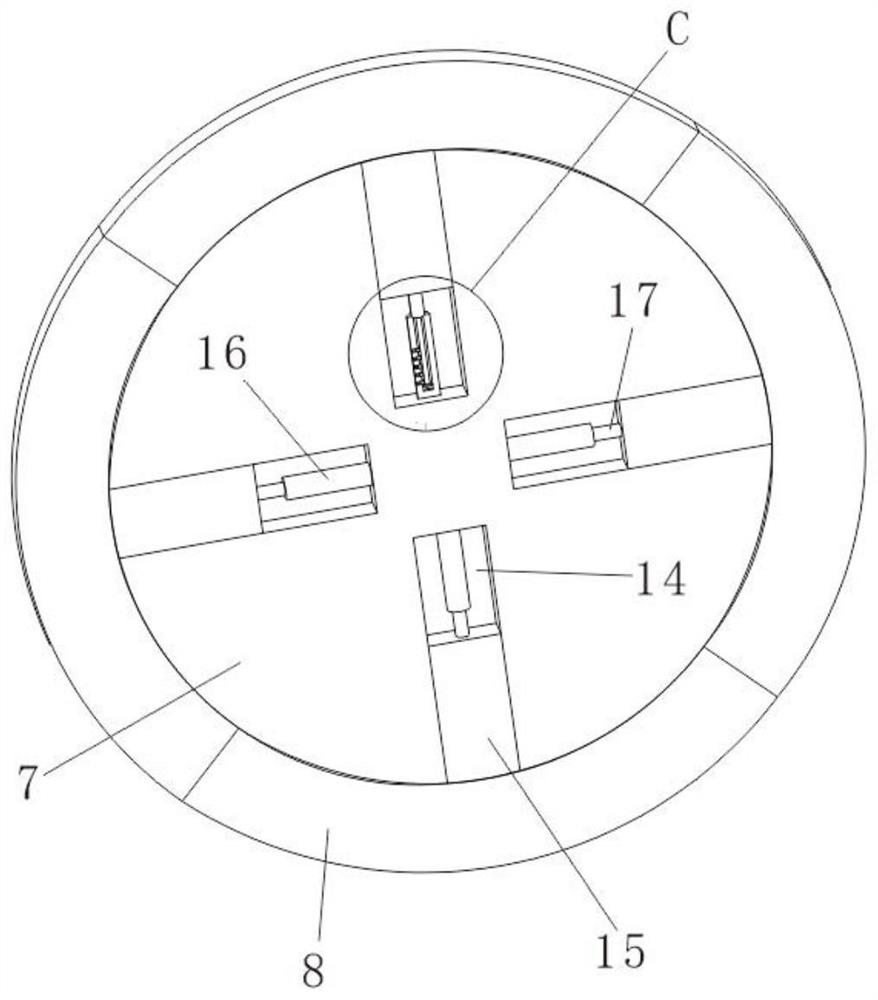

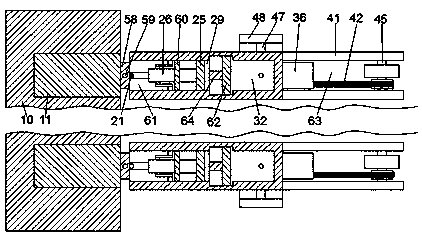

Stent crimping assembly and method

A stent crimping assembly is provided for crimping a stent from a first diameter to a reduced second diameter. The assembly includes a set of two or more blade devices each having a proximal portion, a downstream distal portion, and a respective edge wall extending from the proximal portion to the distal portion. Each respective edge wall is oriented relative to one another, in a respective crimp position, to collectively define an elongated conical-shaped crimp aperture. The conical-shaped crimp aperture at the respective proximal portion of each blade is formed for receipt of at least a portion of the stent in the first diameter. The crimping assembly further includes a drive assembly associated with each blade device and configured to independently displace each blade edge wall in a manner substantially along a respective predetermined first path from the respective crimp position to a respective retracted position, oriented a predetermined incremental distance from the crimp position in a respective proximal direction.

Owner:ABBOTT LAB INC

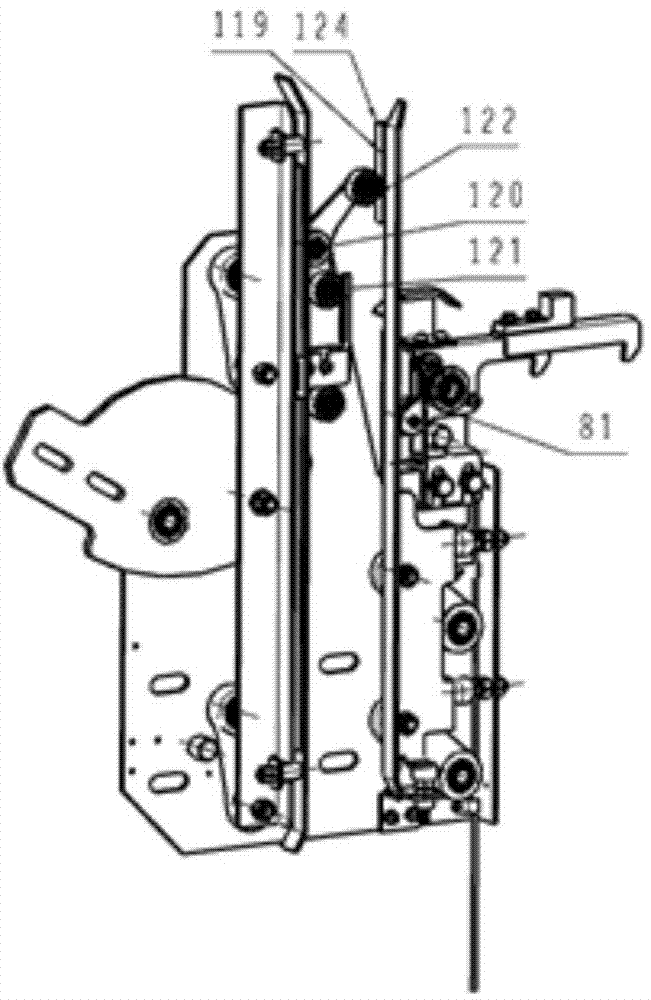

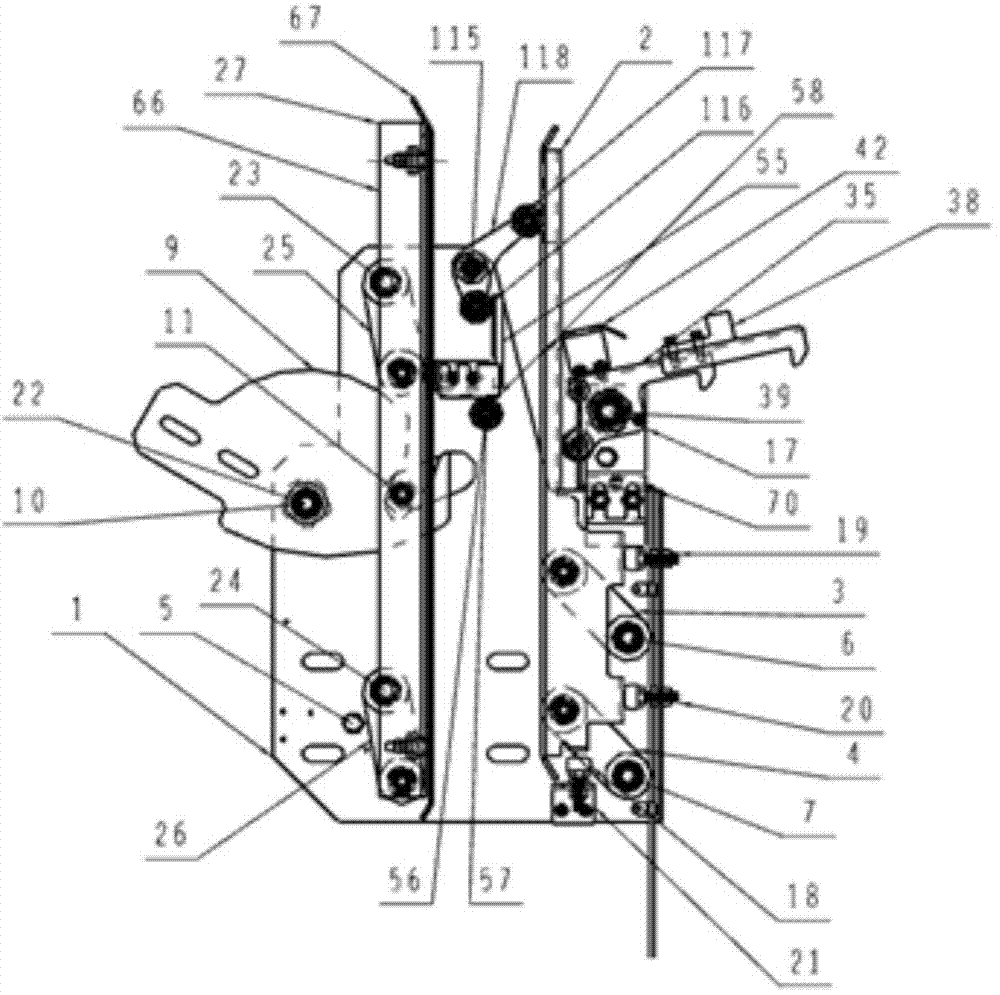

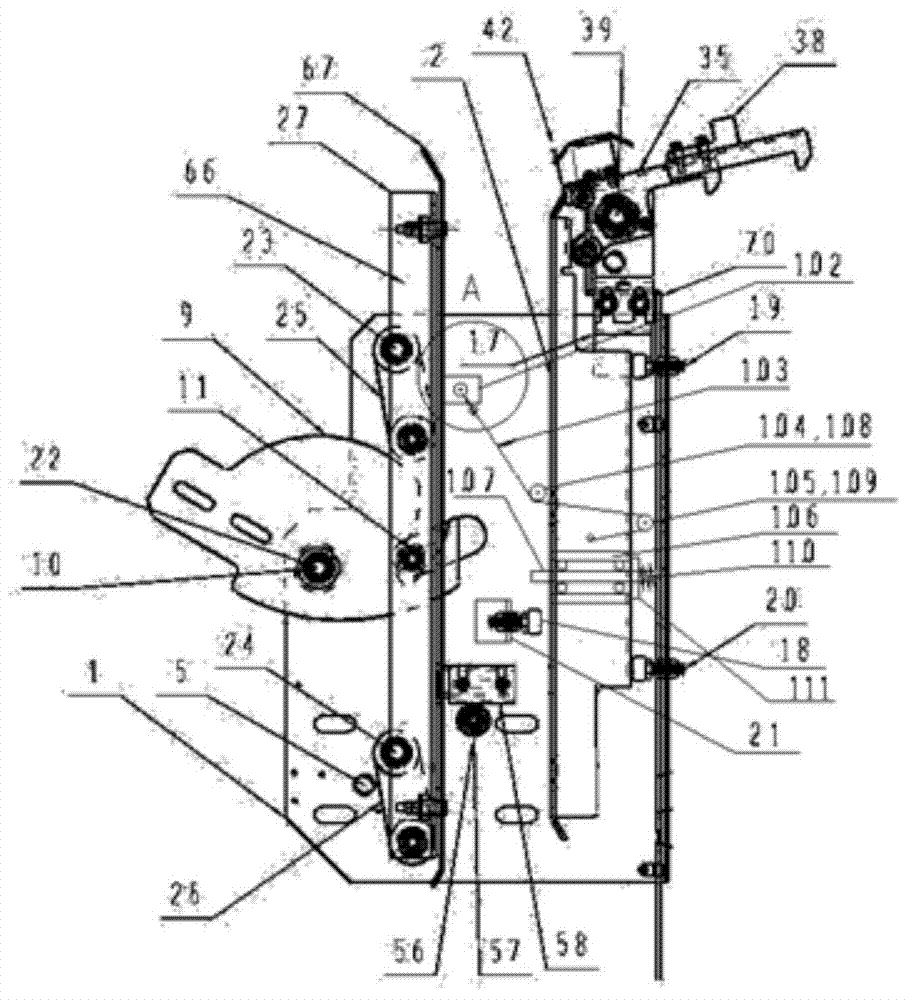

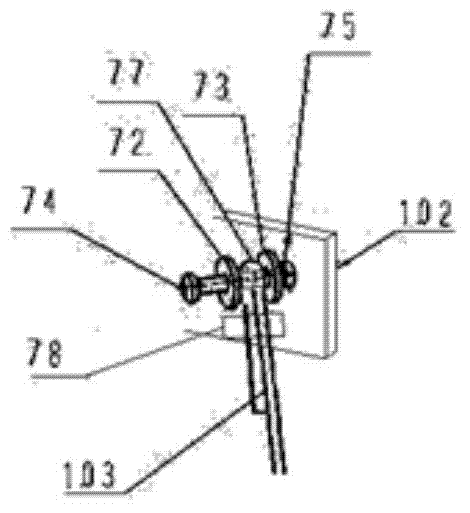

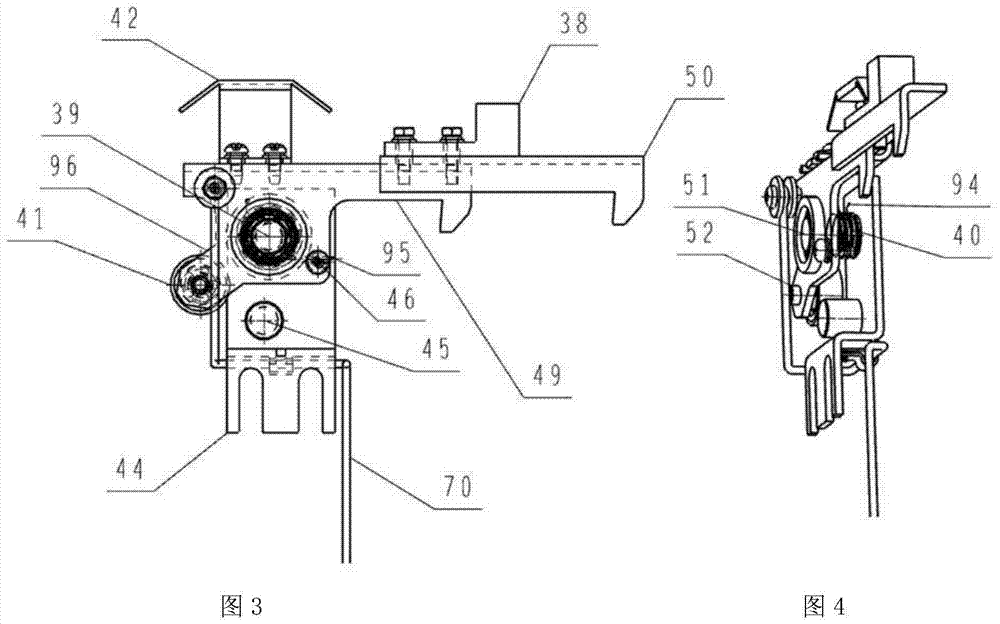

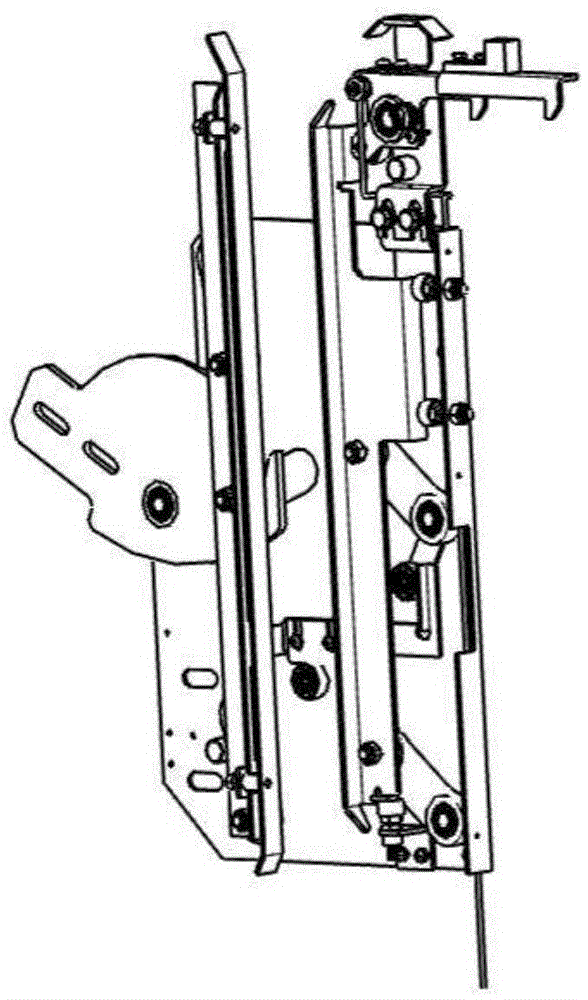

Asynchronous door knife with car lock, elevator door motor and car system

The invention discloses an asynchronous door knife with a car lock. When a second unlocking blade device is suffered from the driving force in the door opening direction, a poking rod of the second unlocking blade device moves to the door opening direction, and drives a lever wheel component to rotate; when the lever wheel component rotates, a first unlocking blade is pushed to swing to the unlocking direction under the guide effect of a guide mechanism; and the first unlocking blade drives a rotating hook of a rotating latch component to rotate to the unlocking direction, so that the rotating hook of the rotating latch component is released from a fixed hook, and the rotating latch component is unlocked. The asynchronous door knife has the functions of opening the car lock and connecting / disconnecting the opening / closing of the door in place; the car lock is unlocked without arranging such additional mechanisms as a landing door battledore on a landing door device; and in emergent rescue on a flat floor, a landing door is opened, and the unlocking of the car lock is synchronously finished. The invention further discloses an elevator door motor having the asynchronous door knife with the car lock, and a car system adopting the elevator door motor.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

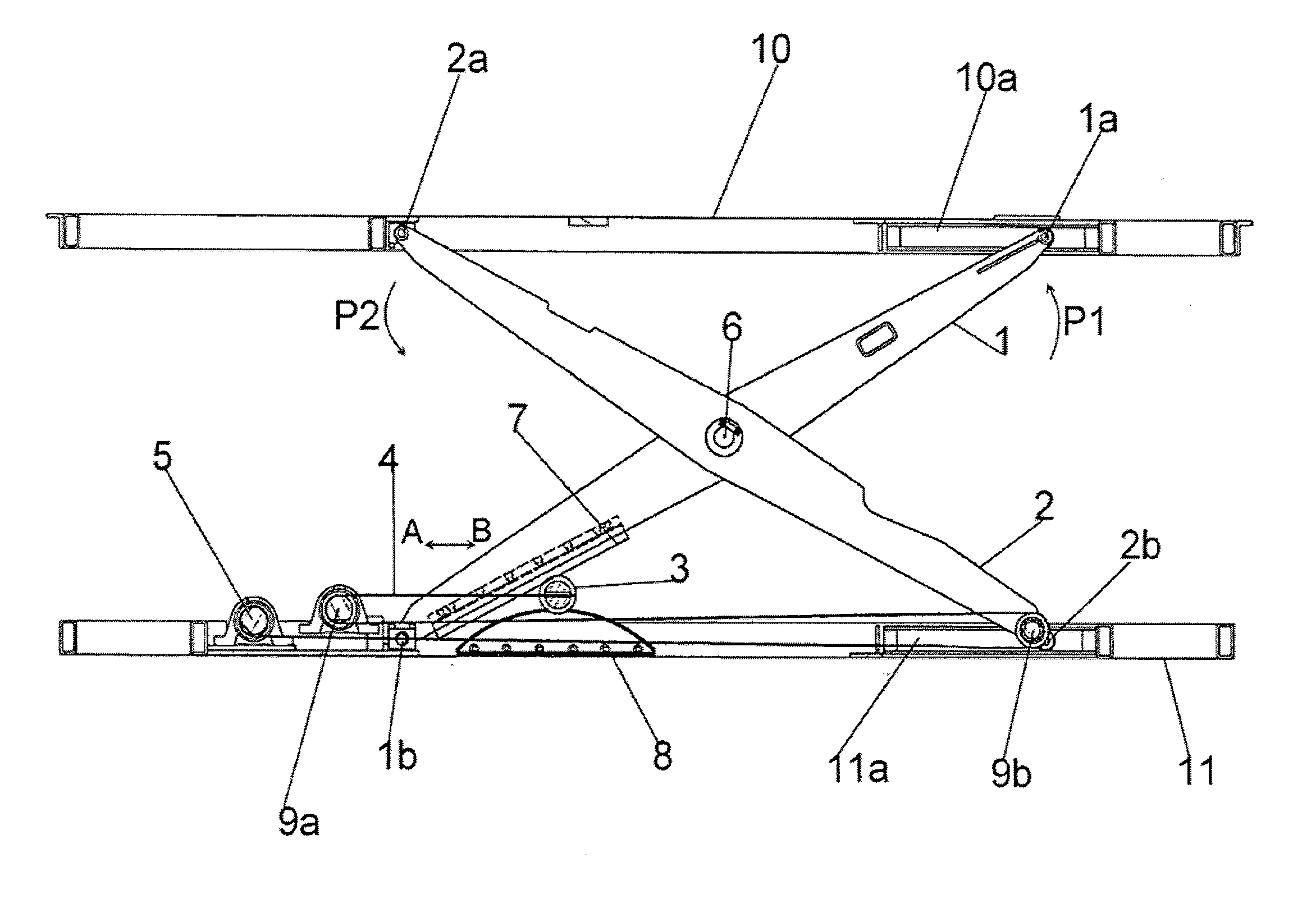

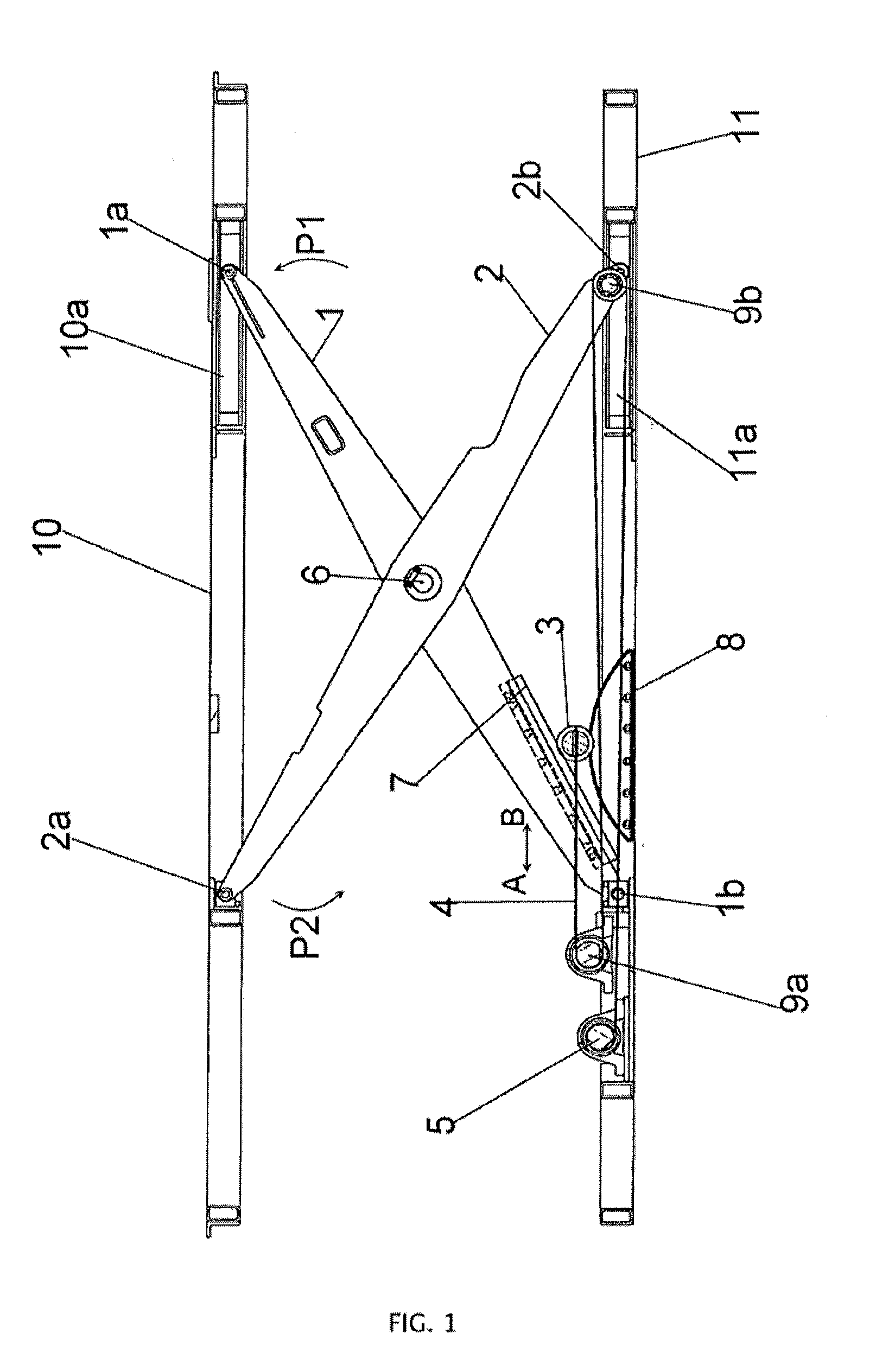

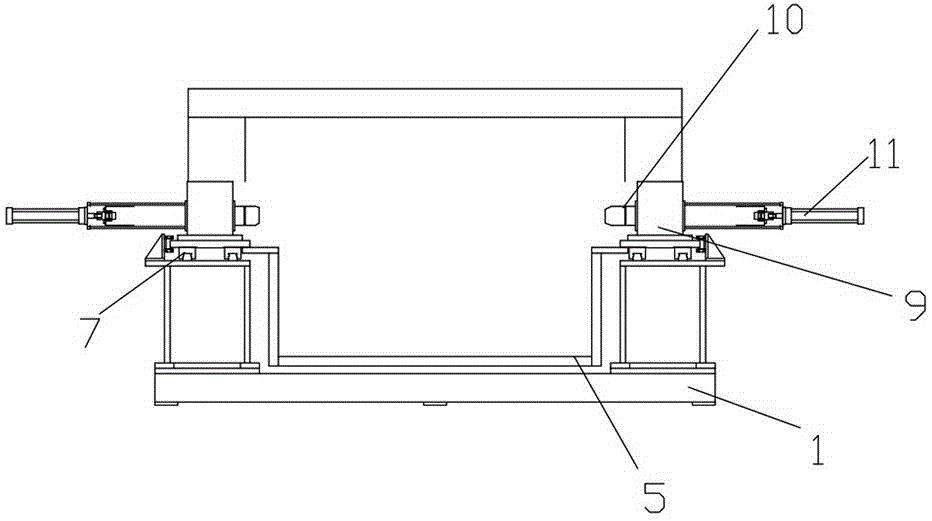

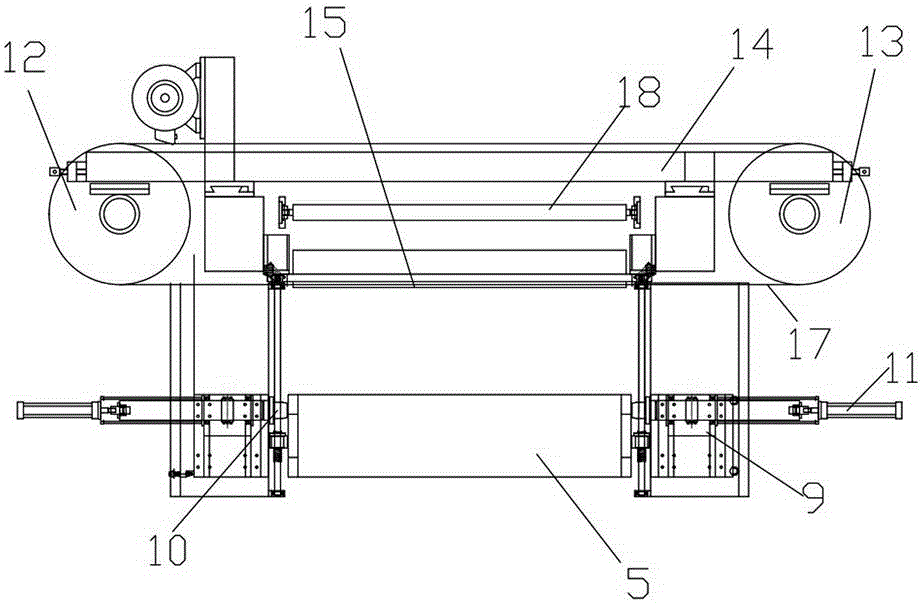

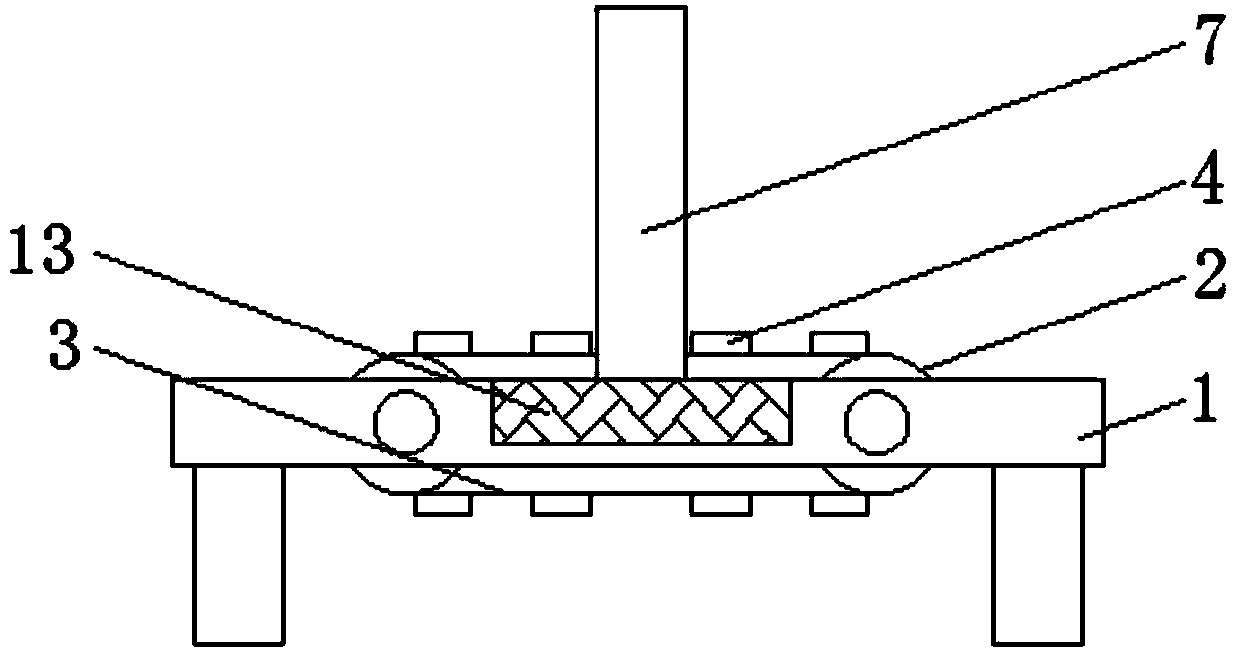

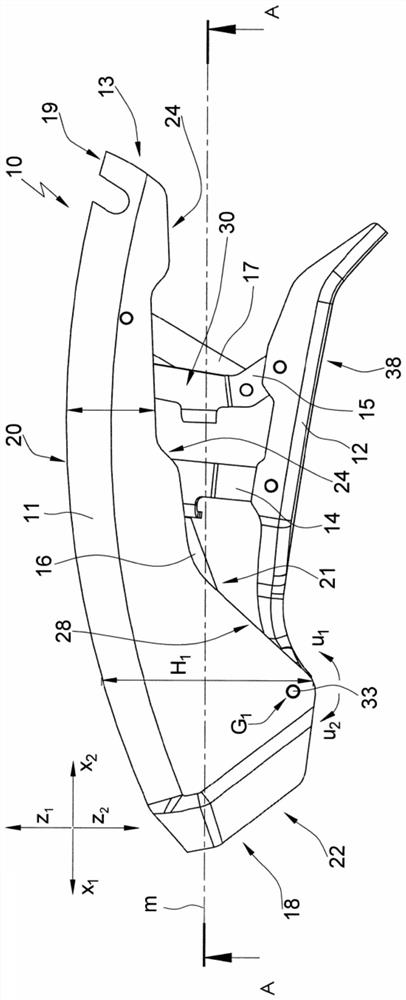

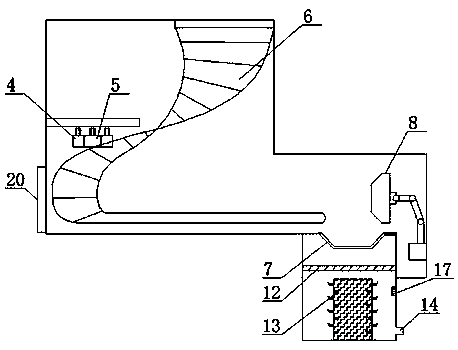

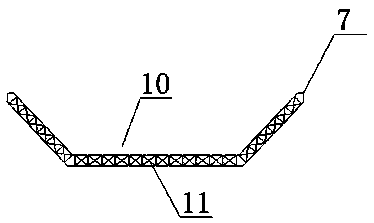

Scissor-type lifting table

A scissor-type lifting table has a carrying device (10) and a base device (11). A scissor mechanism comprising first and second scissor-blade arrangements are arranged between the carrying device (10) and the base device (11). The carrying device (10) can be moved away from the base device (11) by means of a lifting truck (3) which can be moved via at least one traction mechanism (4), by winding up of the traction mechanism (4), and can be raised up in order to open the scissor mechanism and can be lowered in order to close the scissor mechanism by unwinding the traction mechanism (4). At least one lifting cam (8) is provided which is configured to regulate the lifting capacity and along which the lifting truck (3) runs during the raising or lowering of the carrying device (10).

Owner:MOHR CHRISTOPH

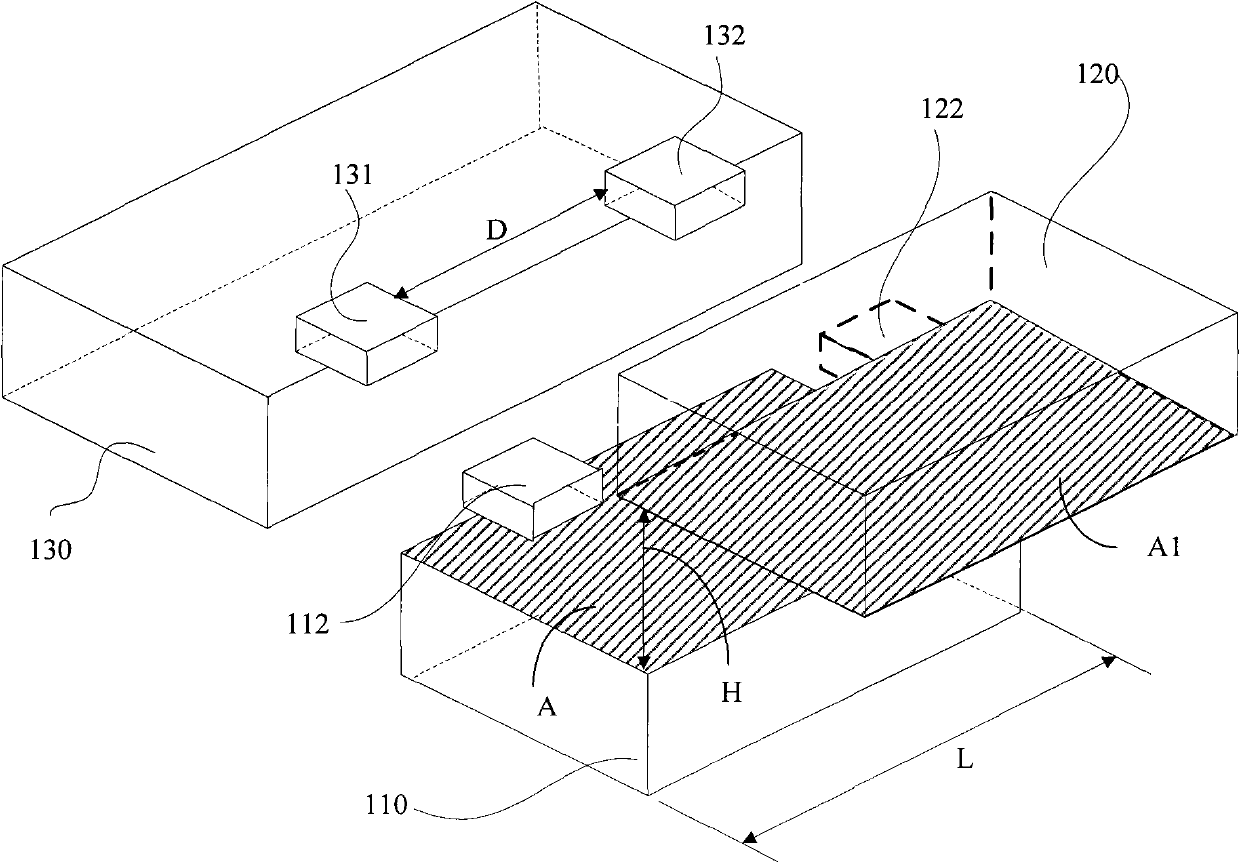

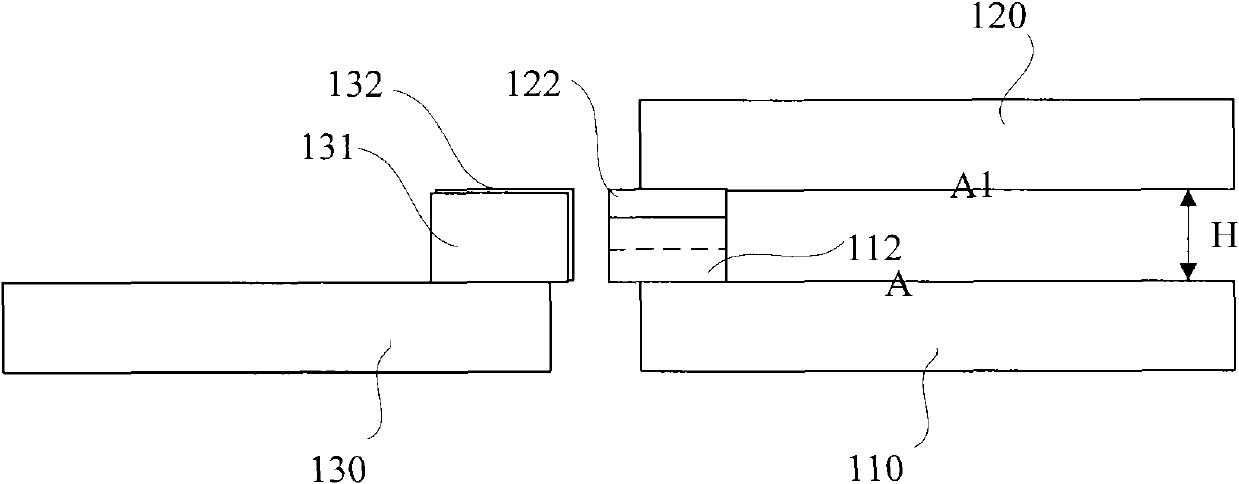

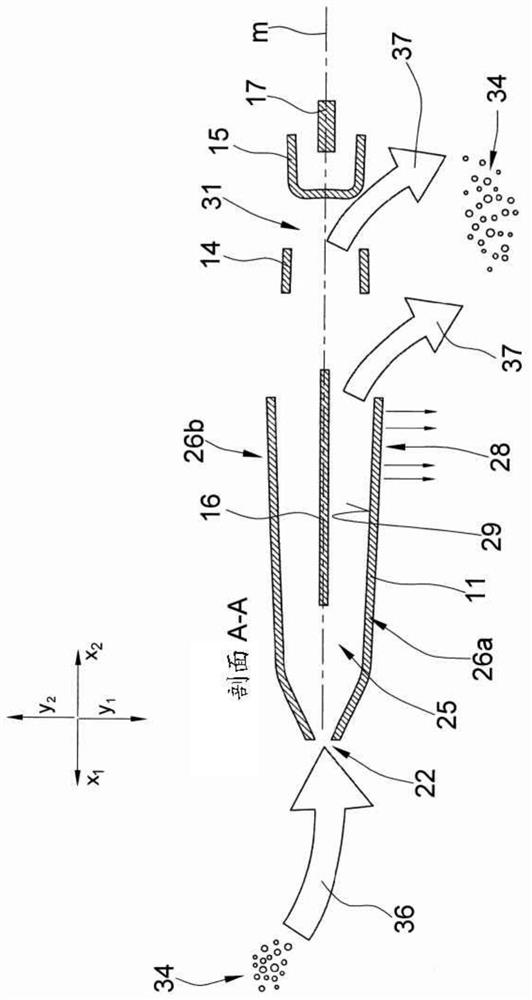

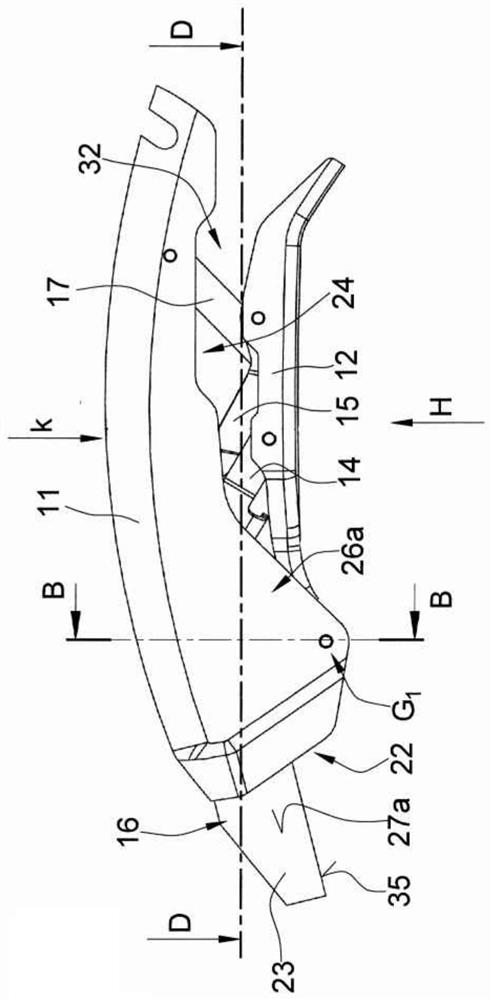

Method of forming a fibrous web and machine therefor

InactiveUS20050034827A1Avoid mixingReduce wake effectsNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

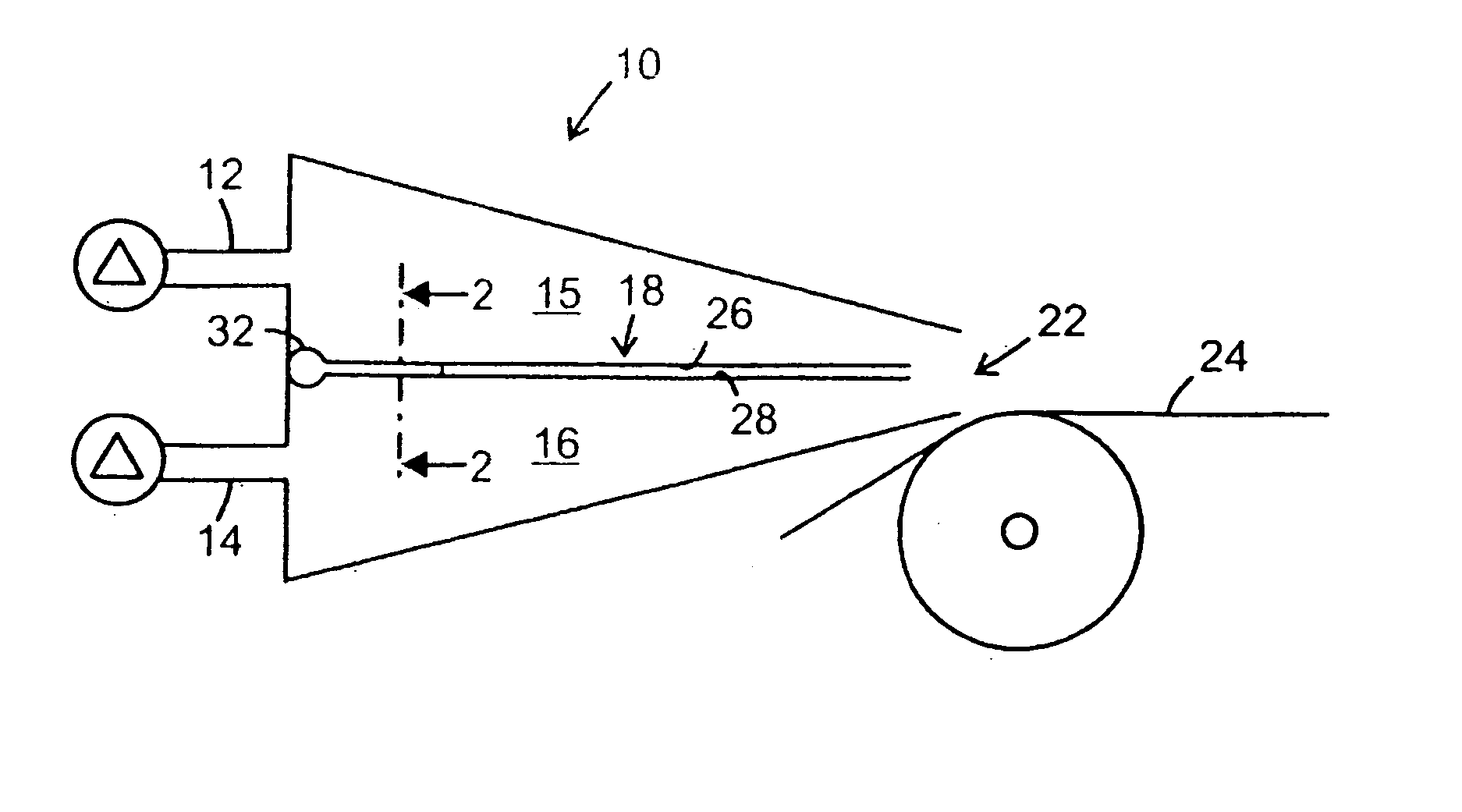

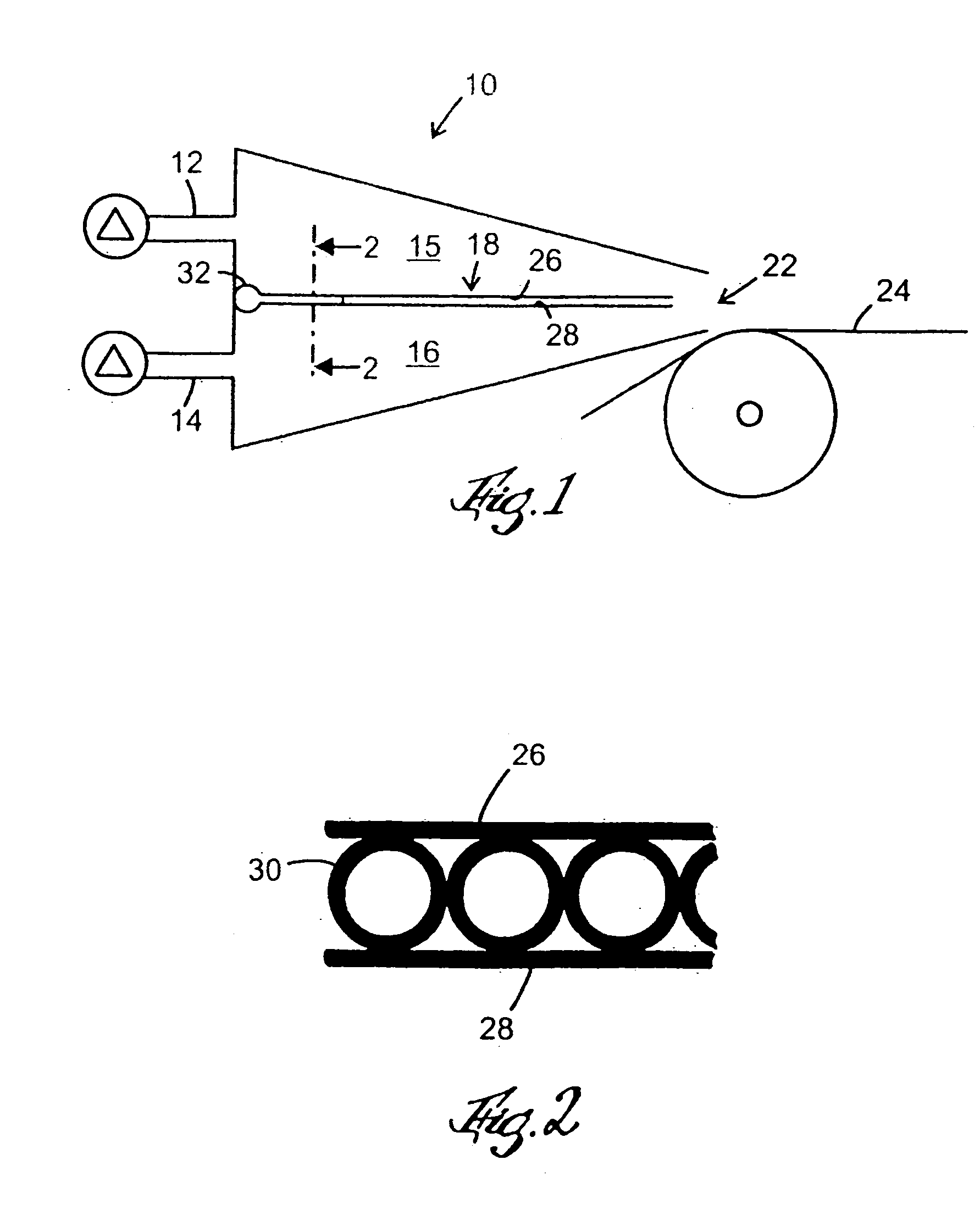

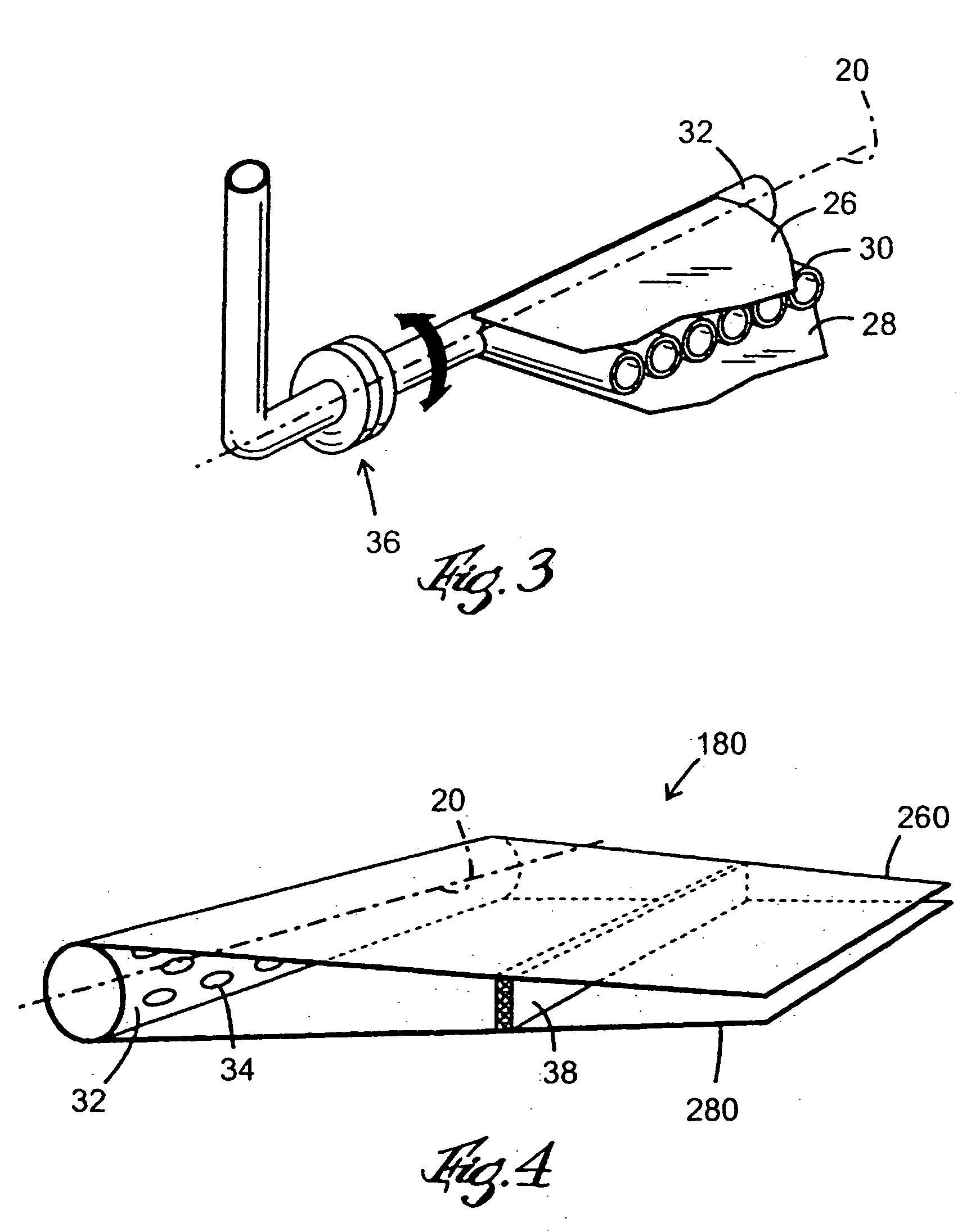

In a method of forming a layered fibrous web, the method includes the steps of leading at least two different fiber suspensions through a head box (10), separating the fiber suspensions from each other by a blade device (18, 180), supplying the fiber suspensions to a web forming device (24) and forming a water layer having a transversely uniform flow at an outlet at the end of the blade device (18, 180), such that the water layer constitutes an extension of the blade device and thereby prevents mixing of the fiber suspensions. The blade device (18, 180) can be freely movable in a substantially vertical direction in order to permit an equalization of pressure between the fiber suspension layers separated by the blade device and thereby reducing wake effects downstream the edge of the blade device. A paper machine for carrying out the method is also disclosed.

Owner:STFI

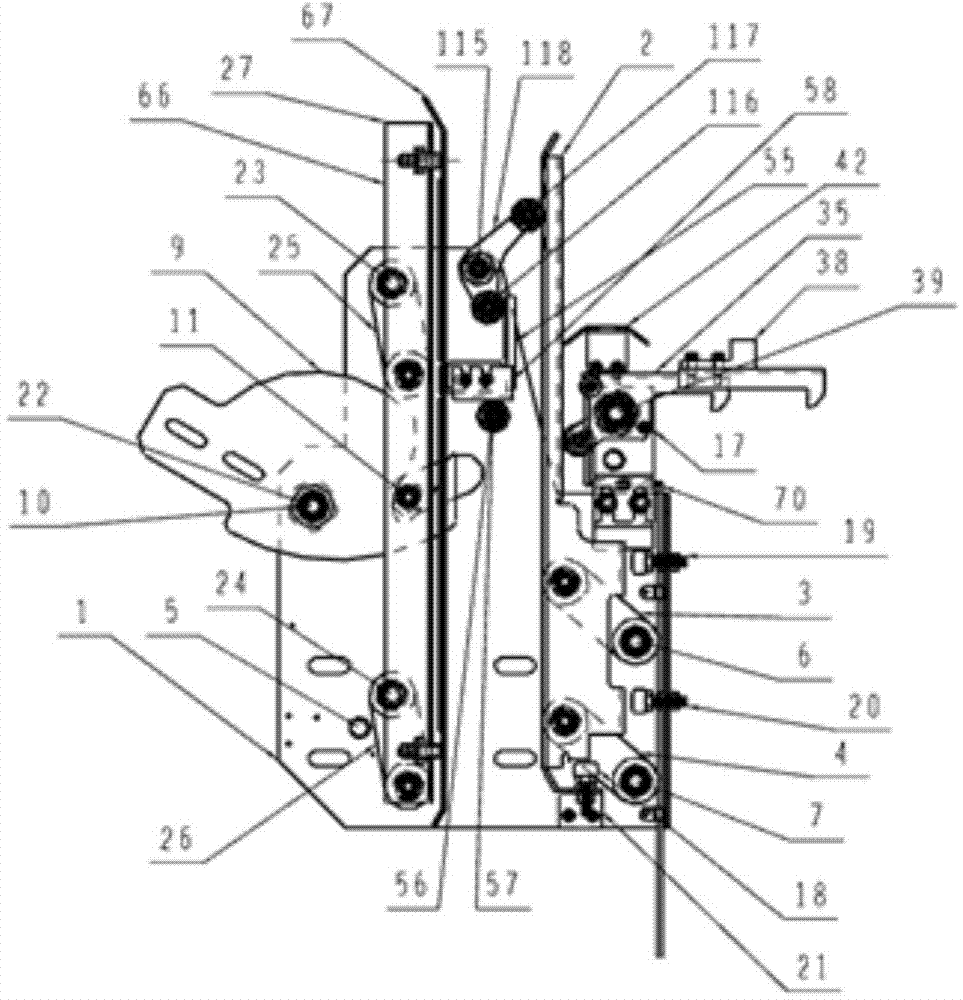

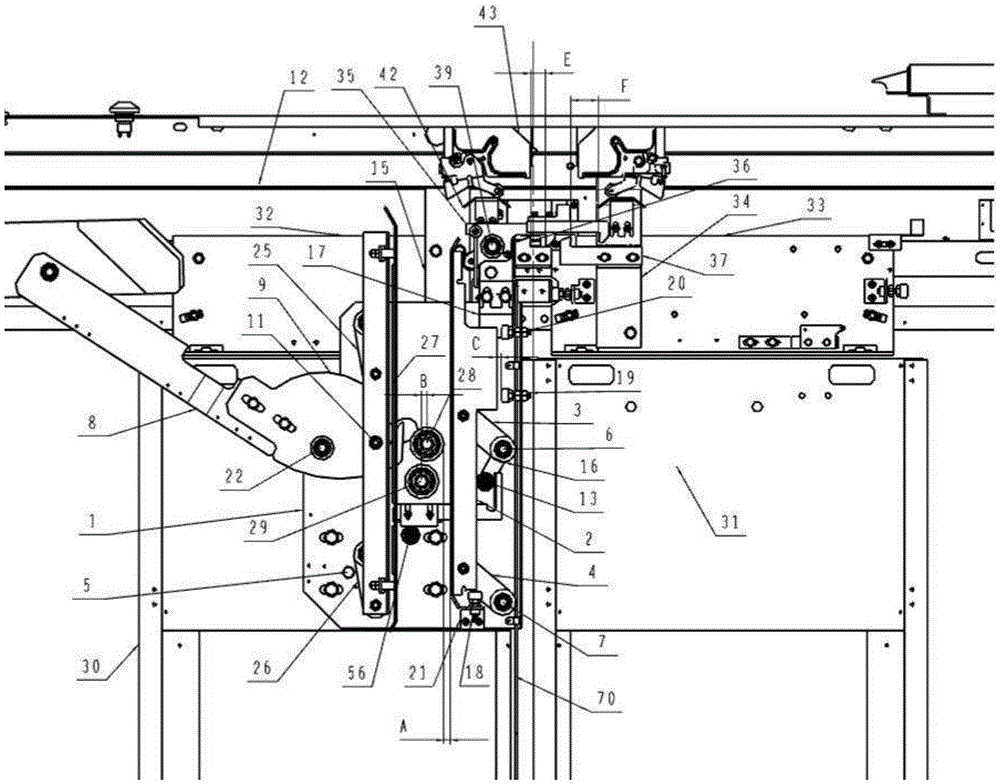

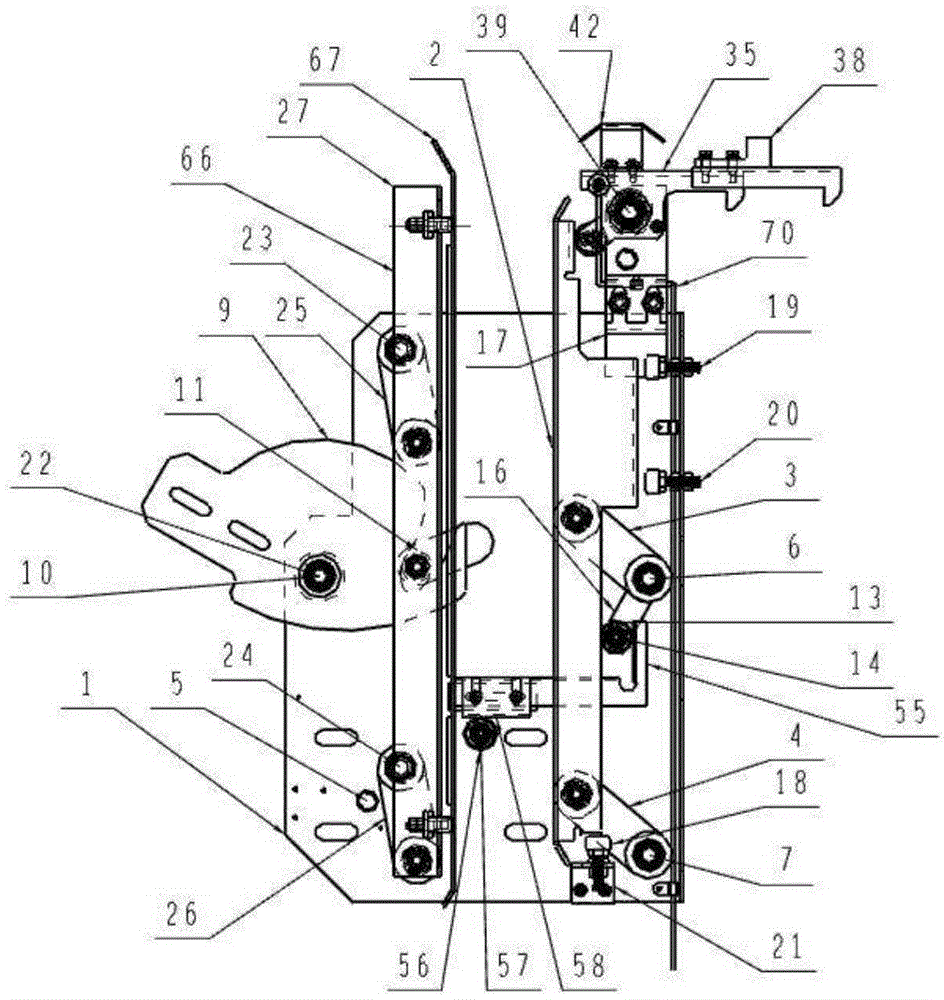

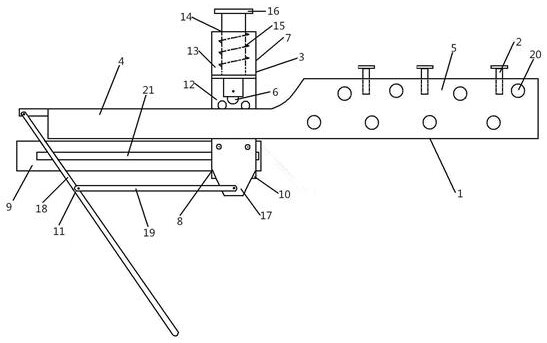

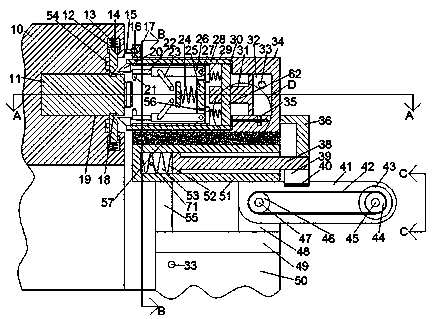

Asynchronous door knife with car door lock, elevator door motor and car door system

ActiveCN104773636AReliable lockingLow integration costElevatorsBuilding liftsEmergency rescueEmbedded system

The invention discloses an asynchronous door knife with a car door lock. When a second unlocking blade device receives pushing force from the door opening direction, the second unlocking blade device drives a first unlocking blade to move horizontally through a rope under the guide effect of a horizontal guide mechanism; the movement of the first unlocking blade drives a rotating hook of a rotating lock hook component to rotate in the unlocking direction, so as to enable the rotating hook of the rotating lock hook component to be unhooked from a fixed hook to unlock the rotating lock hook component; and meanwhile, the rotation of the rotating hook drives a driving door switch trigger to rotate, so as to enable the electrical contact of the pickgurard driving door switch to be disconnected. The asynchronous door knife has the functions of opening the car door lock and switching a door in-place switch; a landing door device is not to be equipped with a landing door pickgurard and other additional mechanism for unlocking of the car door lock, and during emergency rescue of a leveling layer, the car door lock is unlocked by opening a landing door. The invention further discloses an elevator door motor with the asynchronous door knife with the car door lock and a car door system adopting the elevator door motor.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

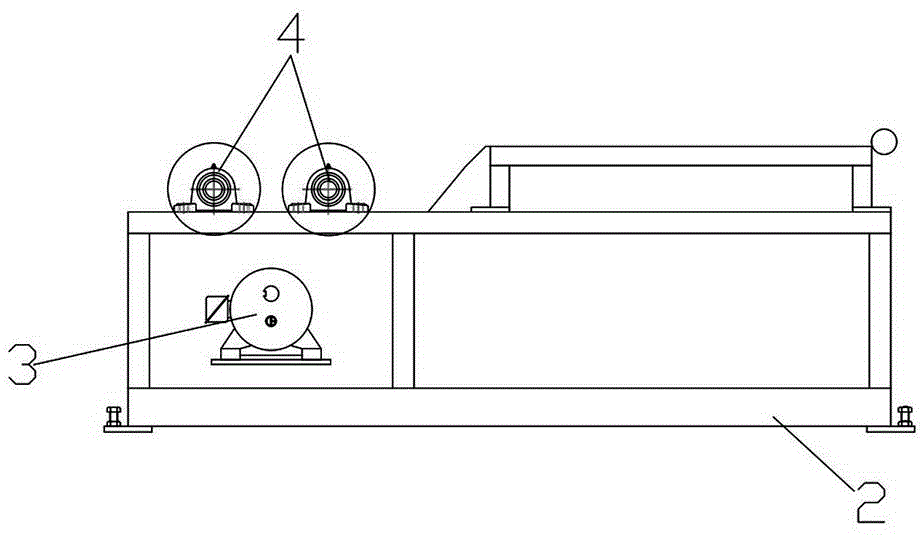

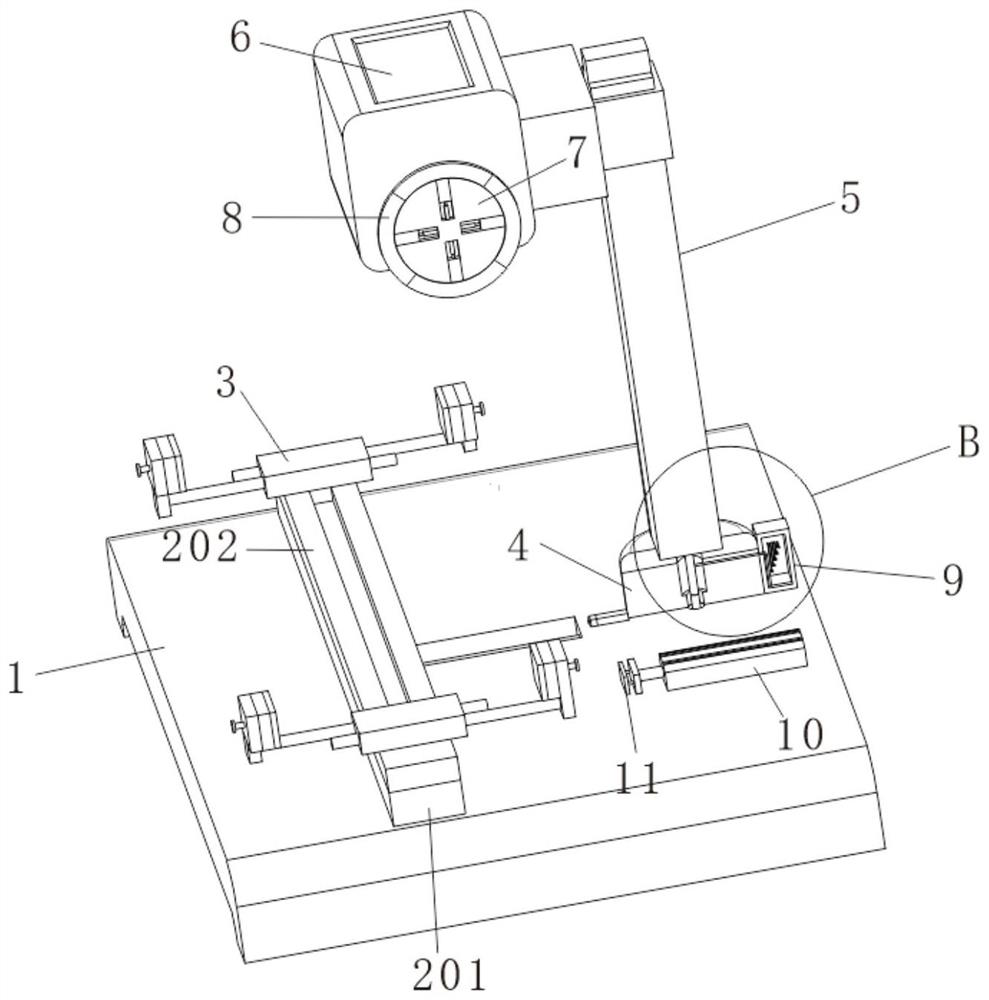

Rubber stripping and cutting machine

ActiveCN103817727AEasy to operateHigh hardnessDispersed particle filtrationDirt cleaningDrive wheelWaste rubber

The invention discloses a rubber stripping and cutting machine in the field of rubber manufacturing equipment. The rubber stripping and cutting machine comprises a frame-type base, a boosting device, a feeding device and a dynamic blade device and is externally connected with an independent material coiling device and a control electric box, wherein the boosting device, the feeding device and the dynamic blade device are mounted on the base, the boosting device is disposed at the rear end of the base and boosts the base forwards via a screw transmission mechanism, the dynamic blade device is disposed in front of the boosting device and comprises a driving wheel, a driven wheel, a cutter rest, a driving motor for driving the driving wheel and a soft blade for connecting the driving wheel with the driven wheel, and when the boosting device boosts forwards, a rubber coil driven to rotate by the feeding device contacts with a blade edge of the soft blade so as to be laterally stripped and cut by the soft blade rotating at a high speed. The dynamic blade device is added, stripping and cutting precision is higher, the soft blade rotating at the high speed can strip and cut rubber in a wider hardness range, and the rubber stripping and cutting machine is applicable to all waste rubber materials.

Owner:广东博森新材料有限公司

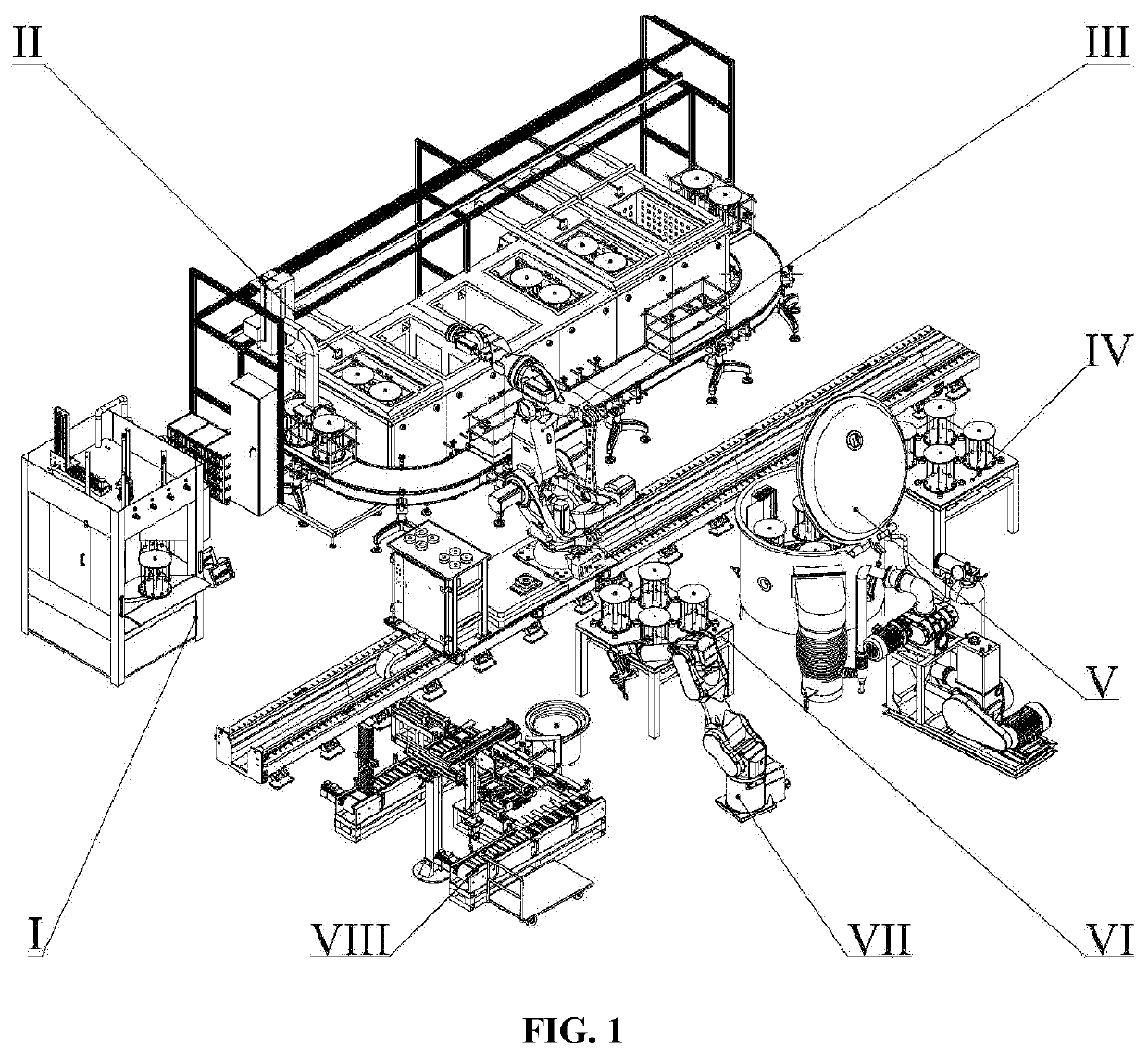

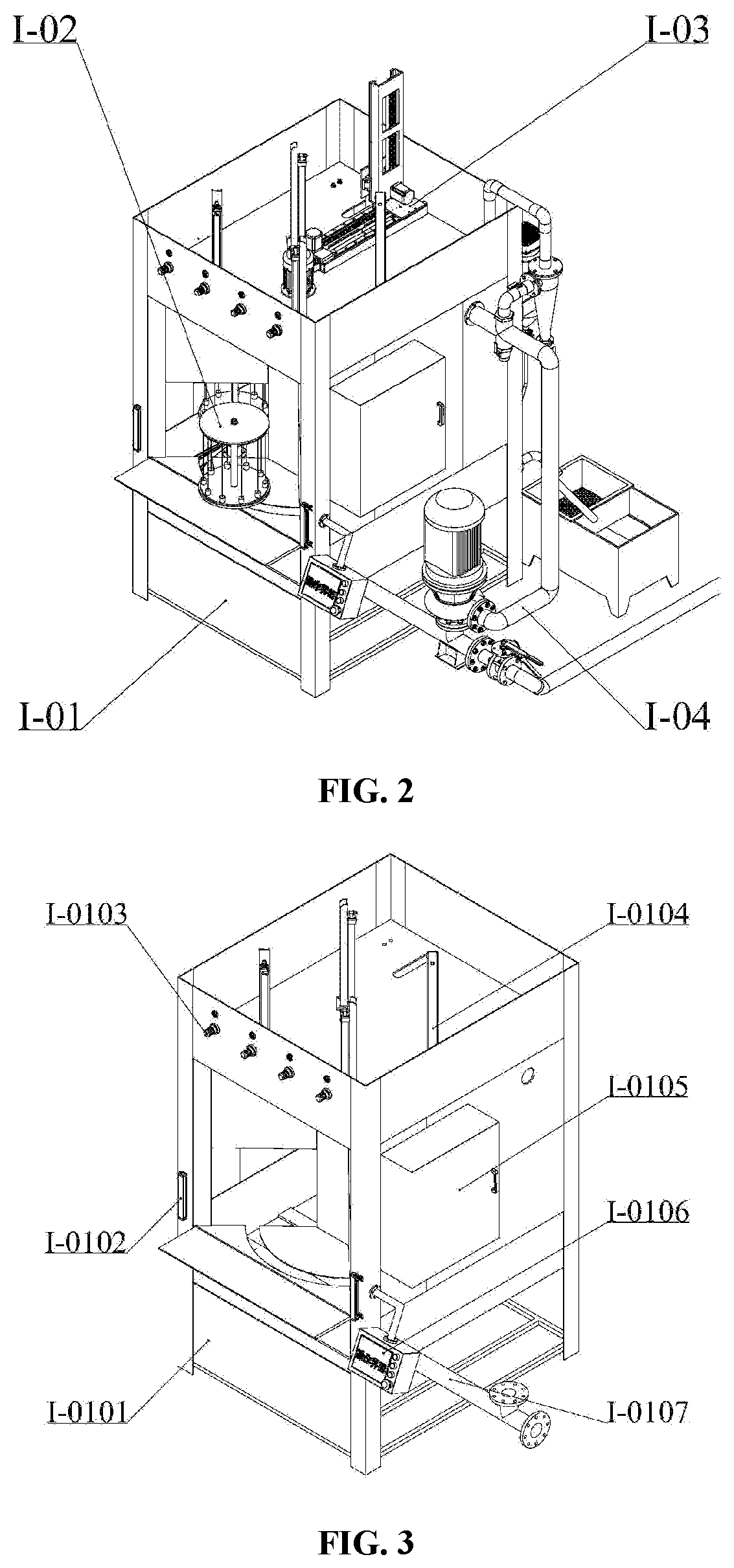

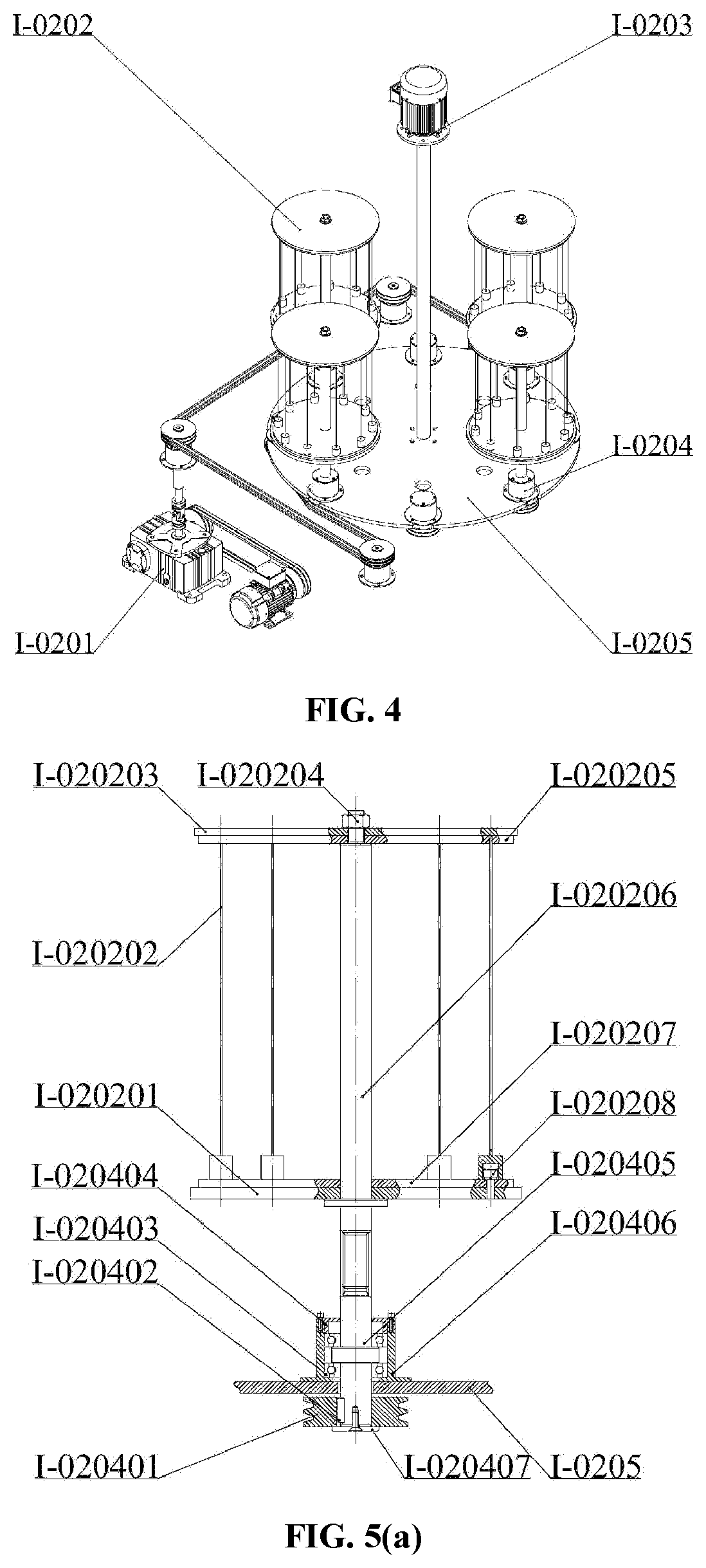

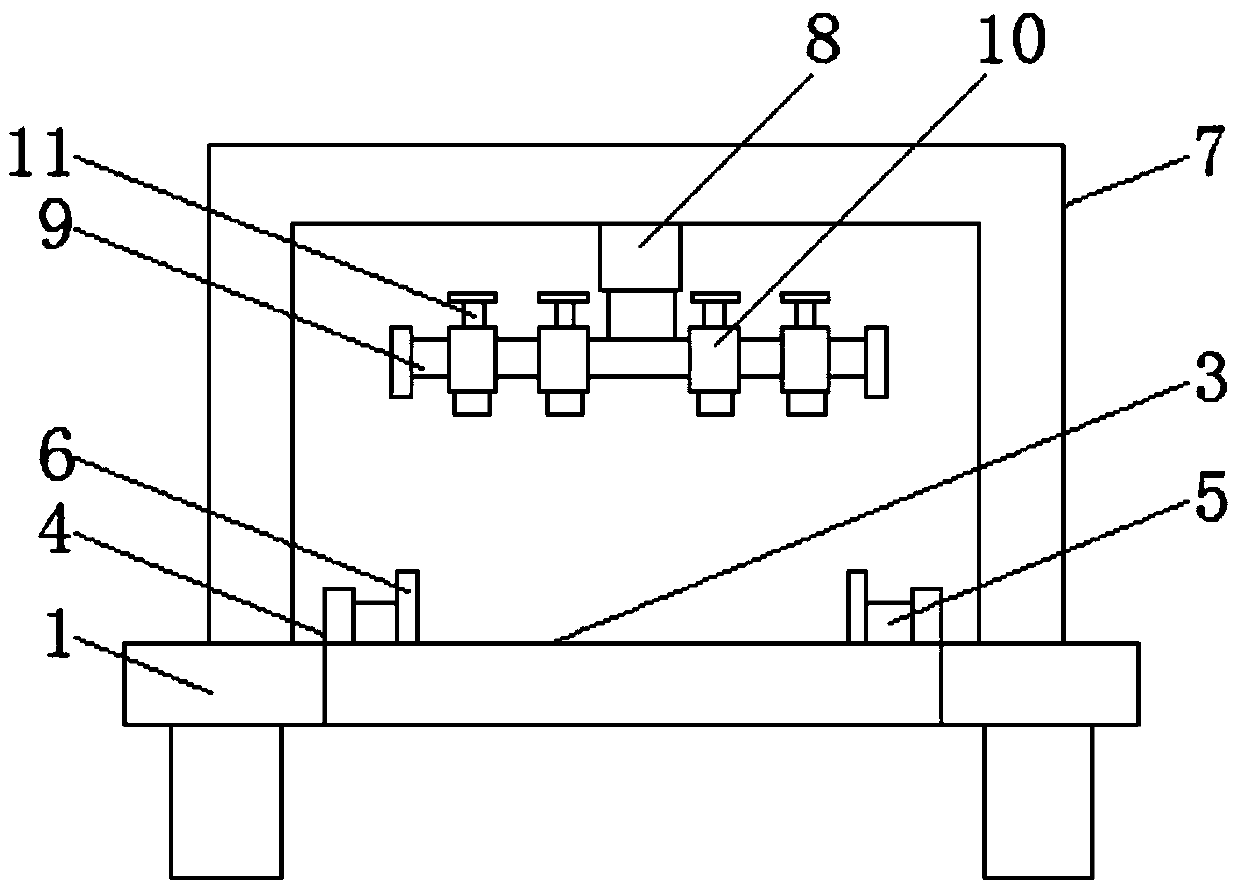

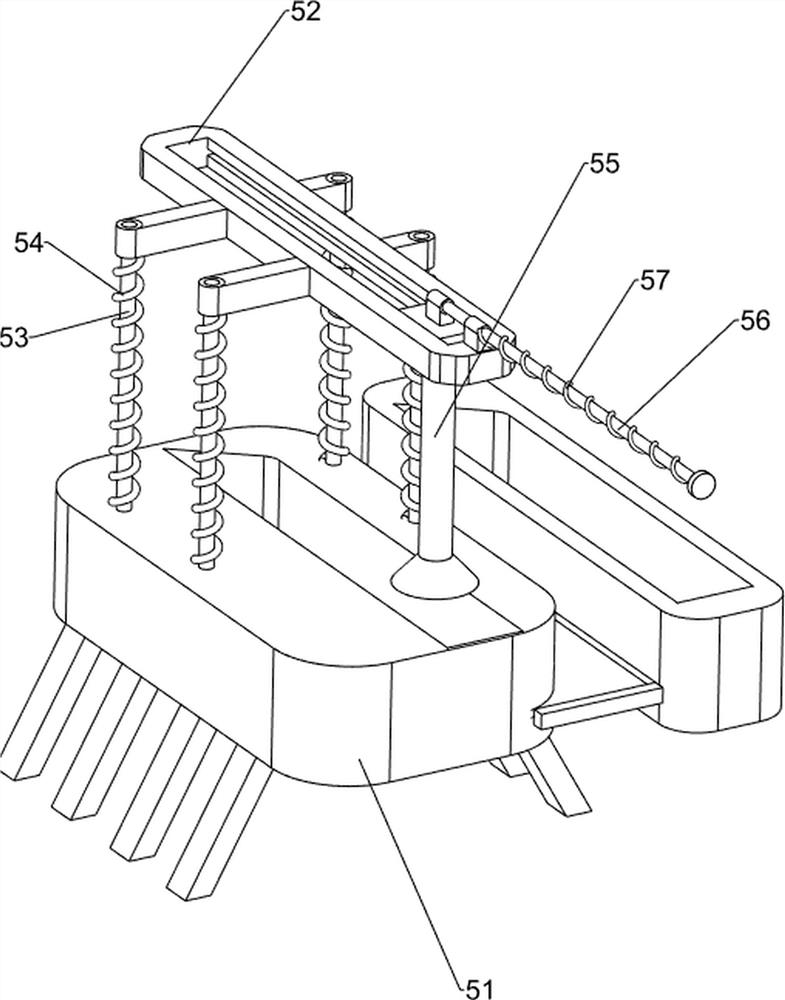

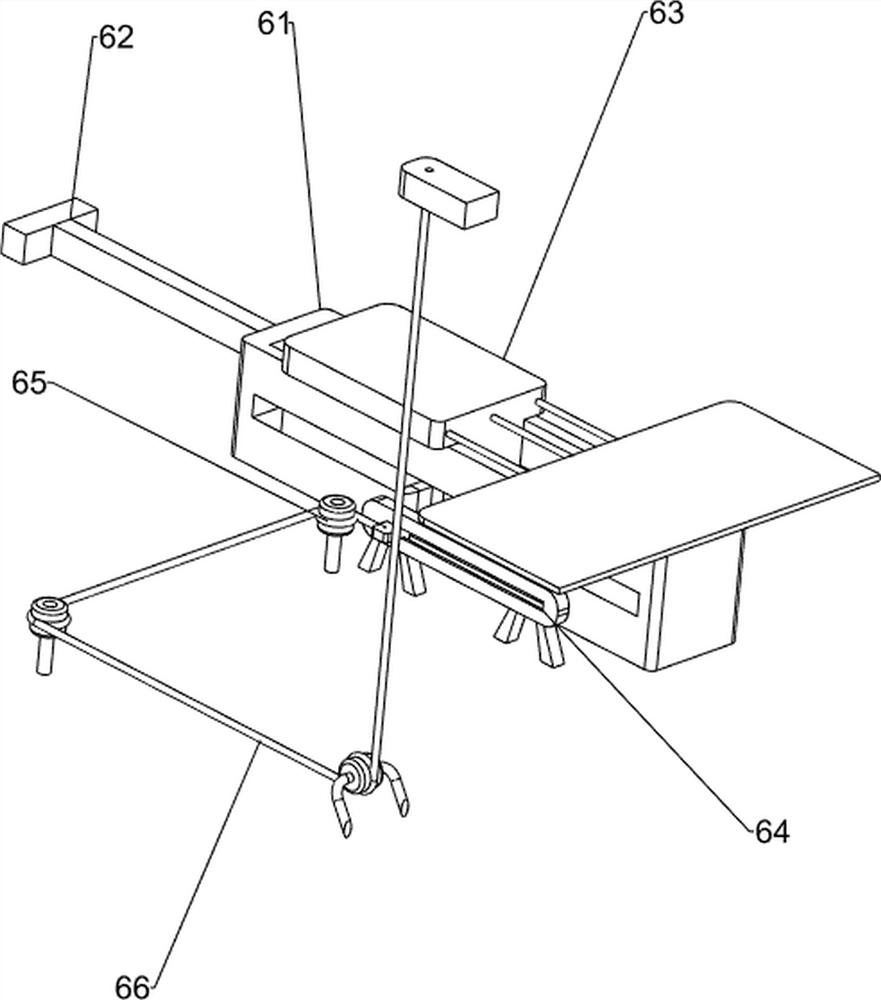

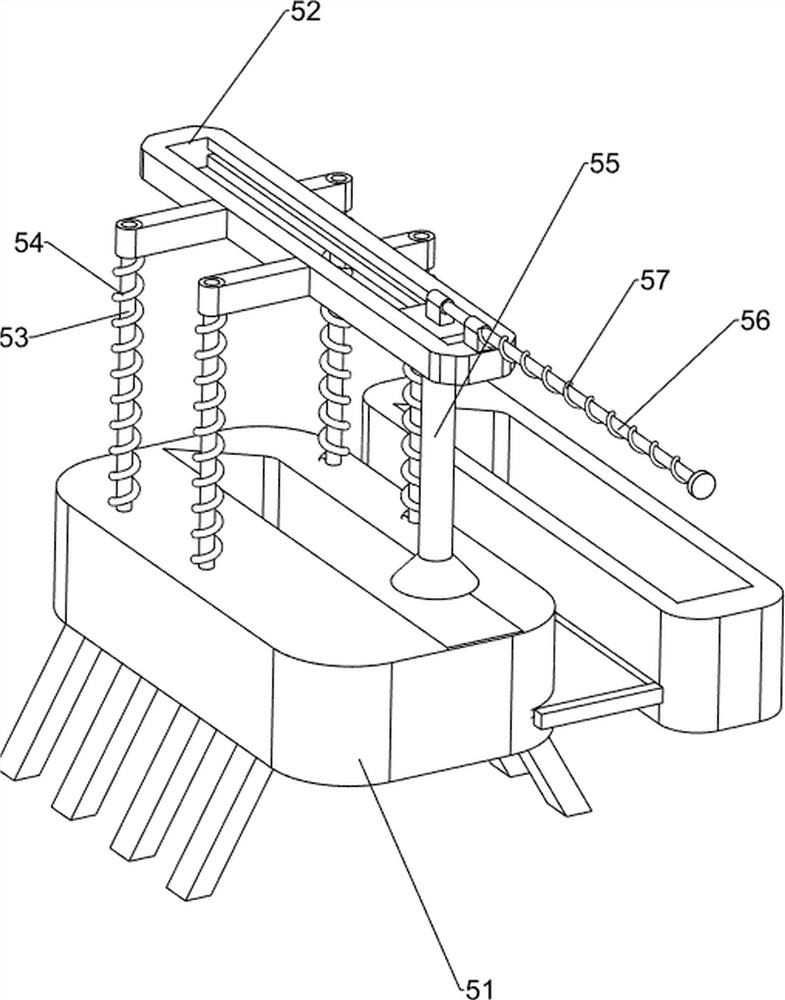

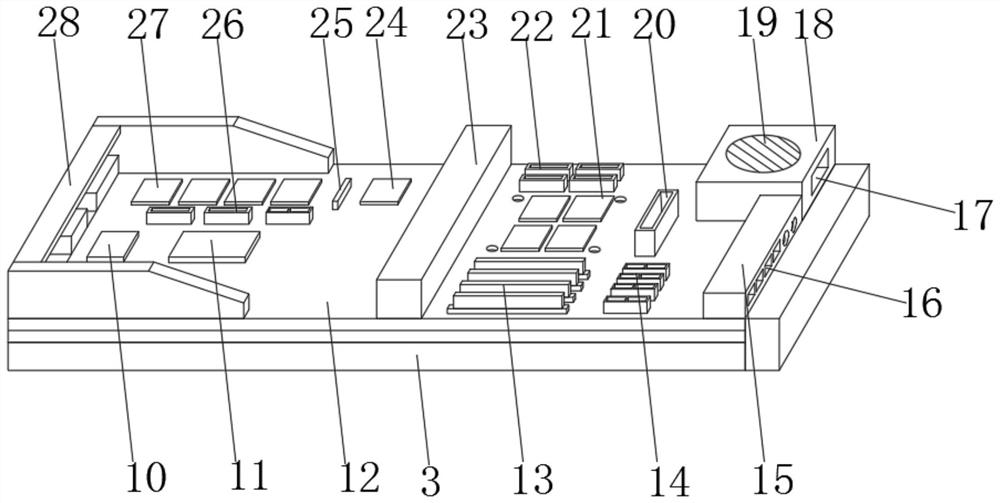

Multi-procedure integrated automatic production line for hard alloy blades under robot control

PendingUS20220055208A1Extended service lifeGood coating effectProgramme-controlled manipulatorBlast gunsRobot controlKnife blades

A multi-procedure integrated automatic production line for hard alloy blades under robot control is provided. The production line includes a rail-guided robot. A cutter passivation device and a blade cleaning and drying device are arranged on one side of the rail-guided robot. A blade-coating transfer table, a blade coating device, a blade boxing transfer table, a blade-tooling dismounting device and a blade boxing device are sequentially arranged on another side of the rail-guided robot. The blade-tooling dismounting device is arranged on one side of the blade boxing transfer table. The production line further includes squirrel-cage toolings for carrying the blades. The squirrel-cage tooling that are loaded with the blades can run among the cutter passivation device, the blade cleaning and drying device, the blade-coating transfer table and the blade boxing transfer table. The blades after being treated through the blade-tooling dismounting device are sent to the blade boxing device.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

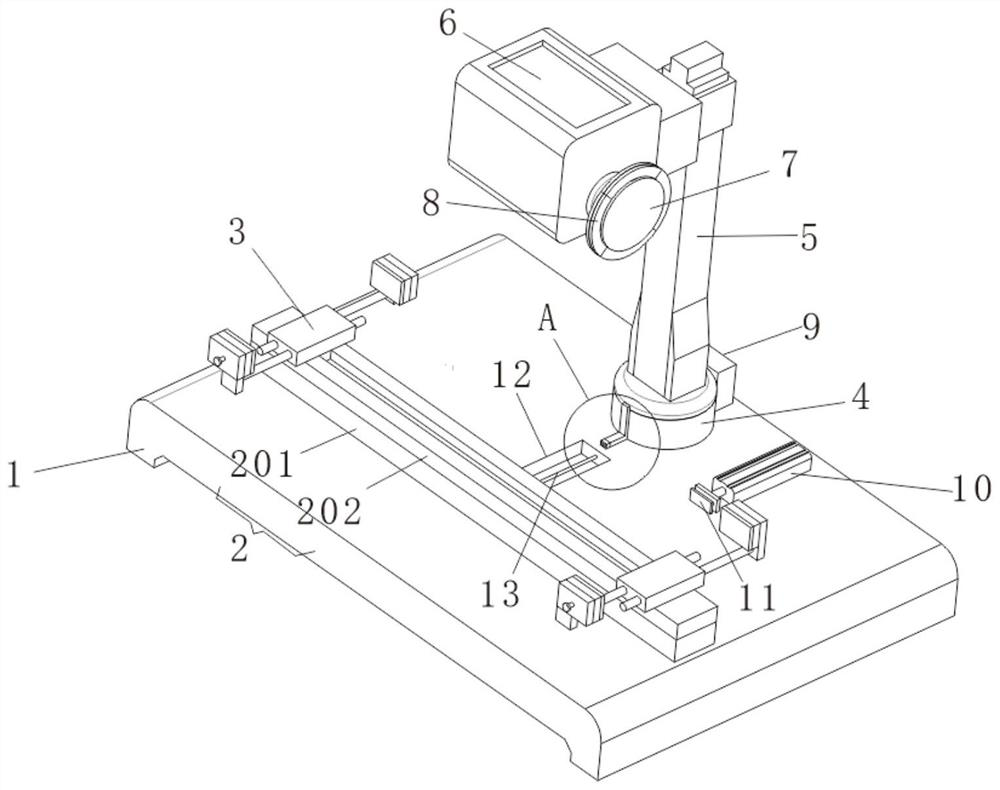

Monocrystalline silicon slicing device capable of freely adjusting size of wafer to be cut

InactiveCN110640919AImprove practicalityReduce wasteFine working devicesWaferingStructural engineering

The invention discloses a monocrystalline silicon slicing device capable of freely adjusting size of a wafer to be cut, and belongs to the technical field of monocrystalline silicon. The slicing device comprises a working platform, wherein two groups of guide rollers are driven by a conveyor belt, a chip collecting box is installed in the center of an inner cavity of the working platform, and theend, away from fixing blocks, of a supporting rod is connected with a clamping device; and an electric telescopic rod is arranged in the center of the bottom of a rack, the bottom of the electric telescopic rod is connected with a fixing rod, the outer wall of the fixing rod is uniformly sleeved with sleeves, and cutting blades are arranged in the centers of the bottoms of the sleeves. The spacingbetween the sleeves is adjusted in the device, so that the device can cut the monocrystalline silicon into different sizes; the monocrystalline silicon is fixed by the clamping device, so that cutting exists in errors caused by the movement of the monocrystalline silicon are prevented; and meanwhile, the cutting blades rotate, so that blocking blocks rotate like fan blades to generate wind force,and chips generated by cutting on the working platform are blown to the chip collecting box, and the chips are prevented from splashing onto the monocrystalline silicon to damage the surface of the monocrystalline silicon.

Owner:江苏晶品新能源股份有限公司

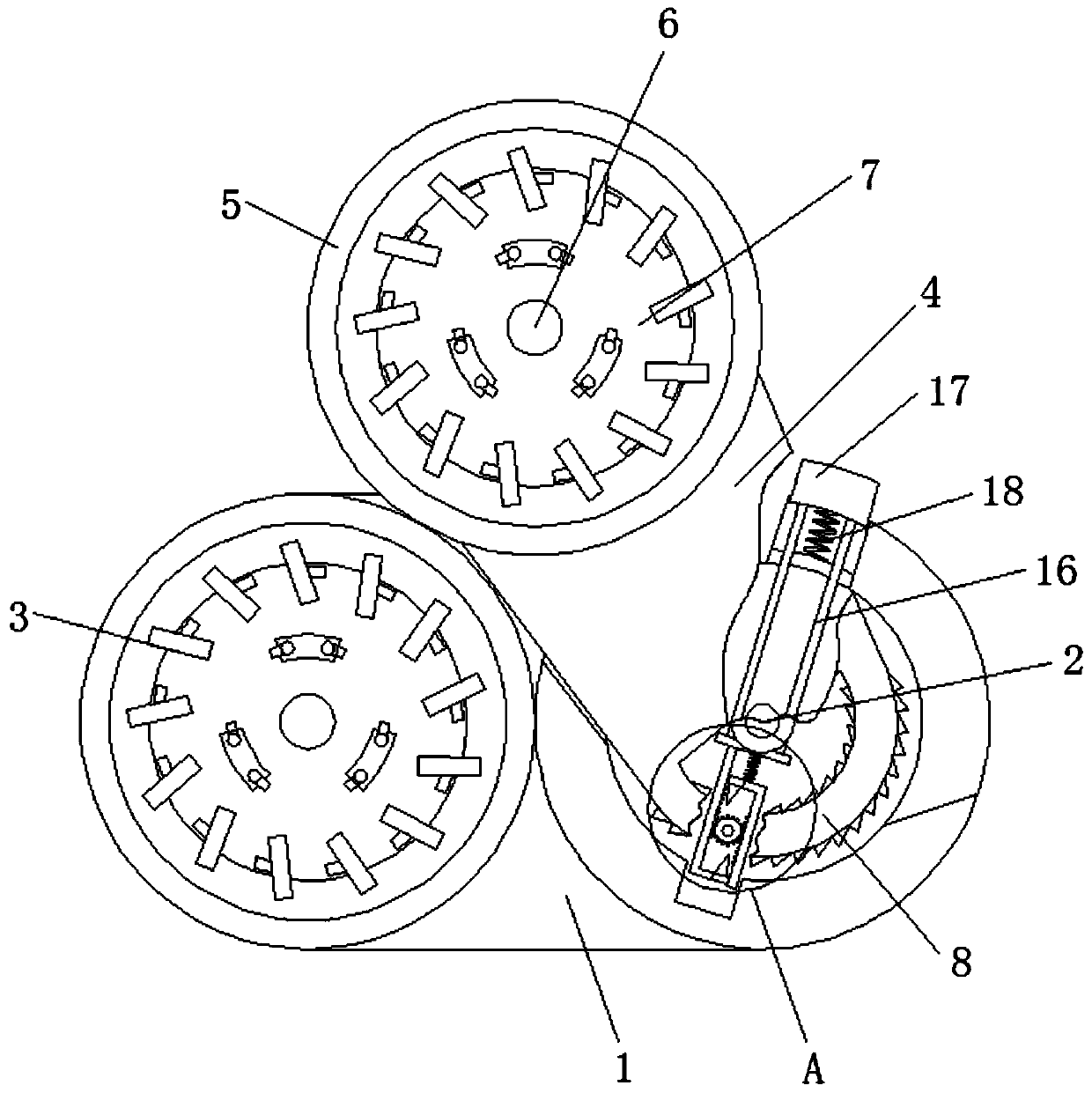

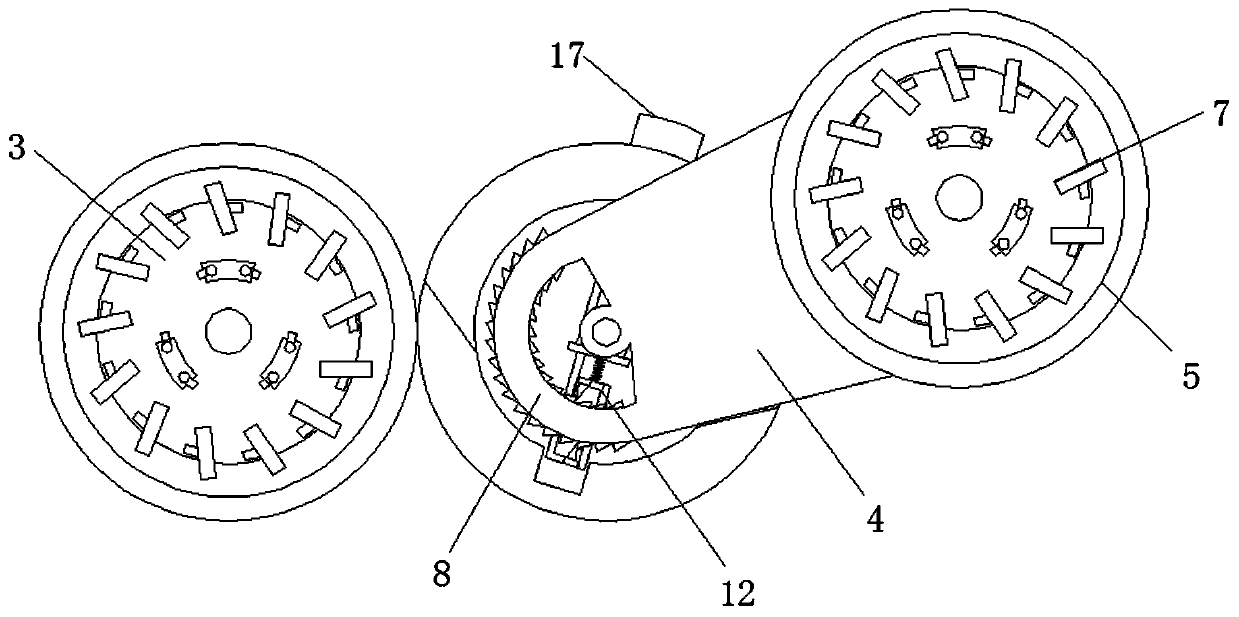

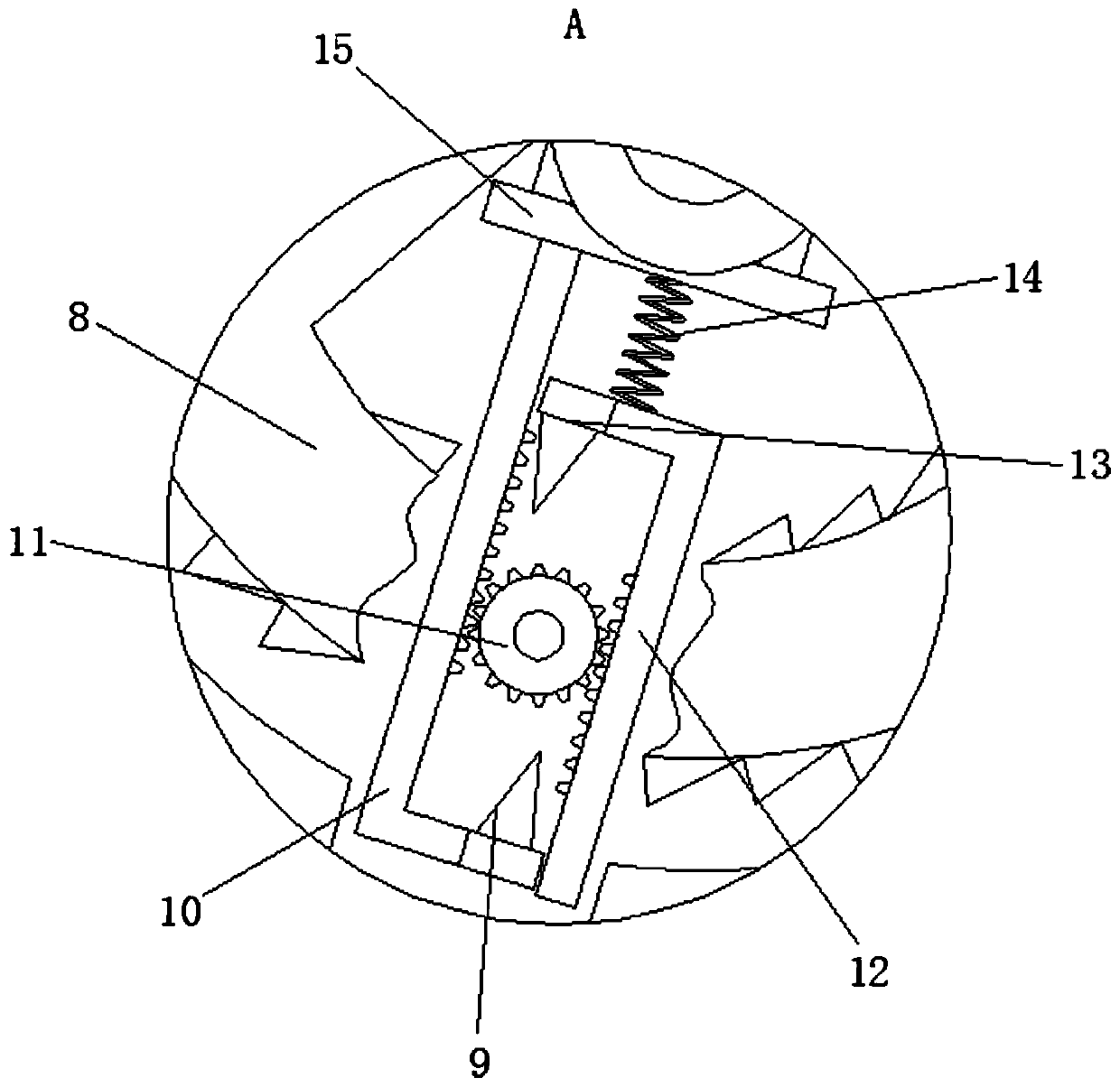

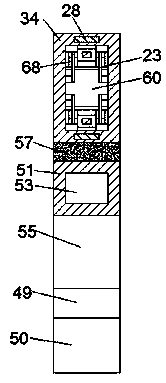

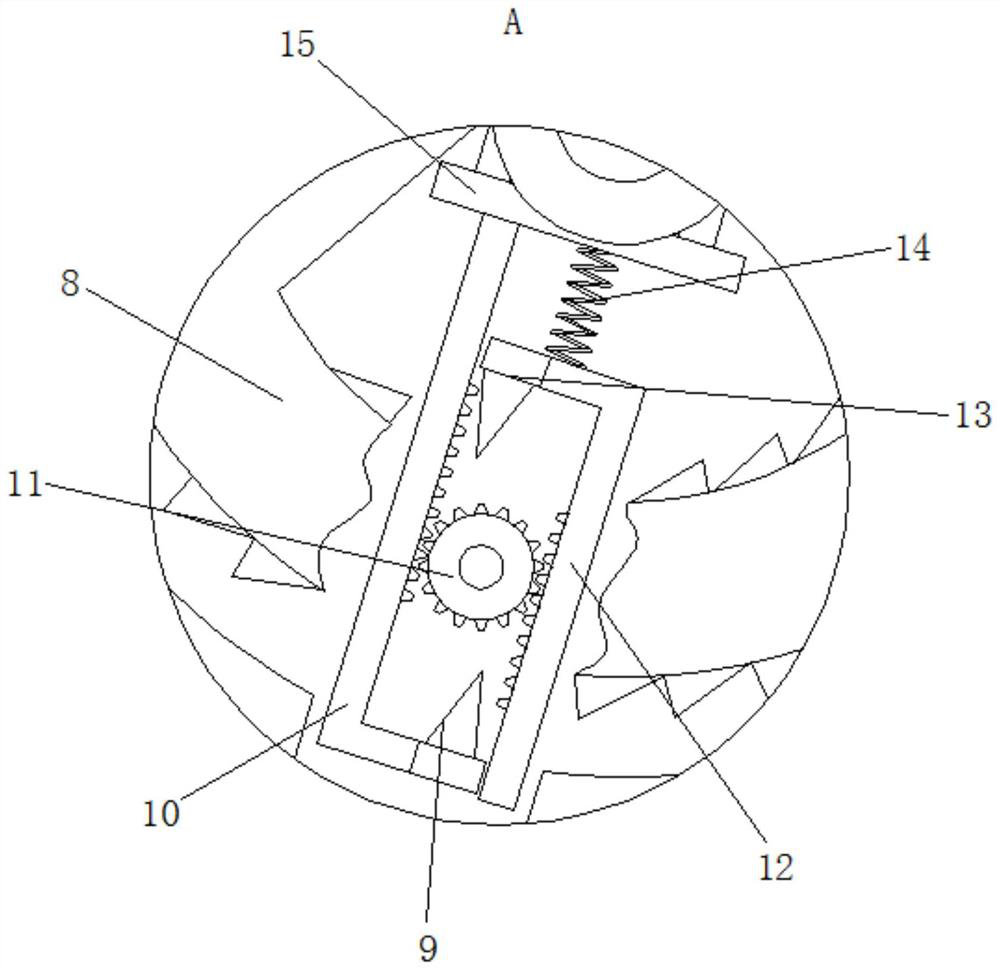

Adjustable electric shaver blade device using ratchet ring positioning principle

ActiveCN111015743AEasy to adjust and rotateFlexible Adjustment StructureMetal working apparatusRatchetKnife blades

The invention relates to the technical field of electronic products, and discloses an adjustable electric shaver blade device using a ratchet ring positioning principle. The adjustable electric shaverblade device comprises a main housing, wherein a first rotating shaft is movably connected to the interior of the main housing; a fixed knife group is fixedly connected to the outer part of the firstrotating shaft; a connecting plate is movably connected to the interior of the main housing; a movable housing is fixedly connected to the outer part of the connecting plate; a second rotating shaftis movably connected to the interior of the movable housing; a movable knife group is fixedly connected to the outer part of the second rotating shaft; and a fan-shaped ratchet ring is fixedly connected to the outer part of the connecting plate. According to the adjustable electric shaver blade device, a first positioning claw, a second positioning claw and the fan-shaped ratchet ring are matchedfor use, the fan-shaped ratchet ring is fixed on the two sides, so that the stability of the fan-shaped ratchet ring is effectively guaranteed, the stability of the movable housing is guaranteed, themovable housing is prevented from shaking, the stability of the movable knife group in the shaving process is guaranteed, and the shaving effect is prevented from being influenced by shaking of the movable knife group.

Owner:义乌路豪电器有限公司

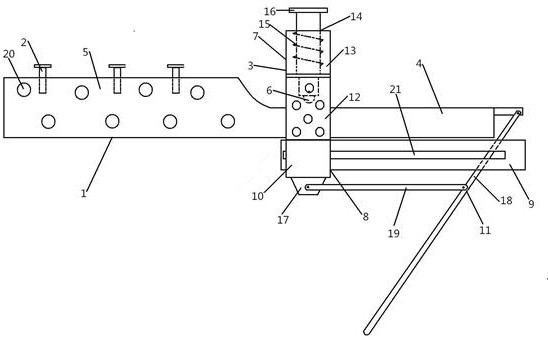

Asynchronous door knife with car door lock, elevator door machine and car door system

The invention discloses an asynchronous door knife having a car door lock; when a second unlocking blade device is suffered from the driving force in the door opening direction, the second unlocking blade device drives a swinging rod arm to rotate; the rotation of the swinging rod arm drives a guide mechanism to swing; the swinging of the guide mechanism drives a first unlocking blade to swing; the first unlocking blade drives a rotating hook of a rotating latch component to rotate to the unlocking direction after swinging, so that the rotating hook of the rotating latch component is released from a fixed hook, and the rotating latch component is unlocked; and meanwhile, the rotation of the rotating hook drives a driving door switch trigger to rotate, so that an electric contact of a beating plate type driving door switch is cut off. The asynchronous door knife has functions of opening the car door lock and opening / closing the door in place, and synchronously finishes the unlocking of the car door lock while opening a landing door in emergency rescue of a flat floor. The invention further discloses an elevator door motor having asynchronous door knife with the car door lock and a car door system adopting the elevator door motor.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

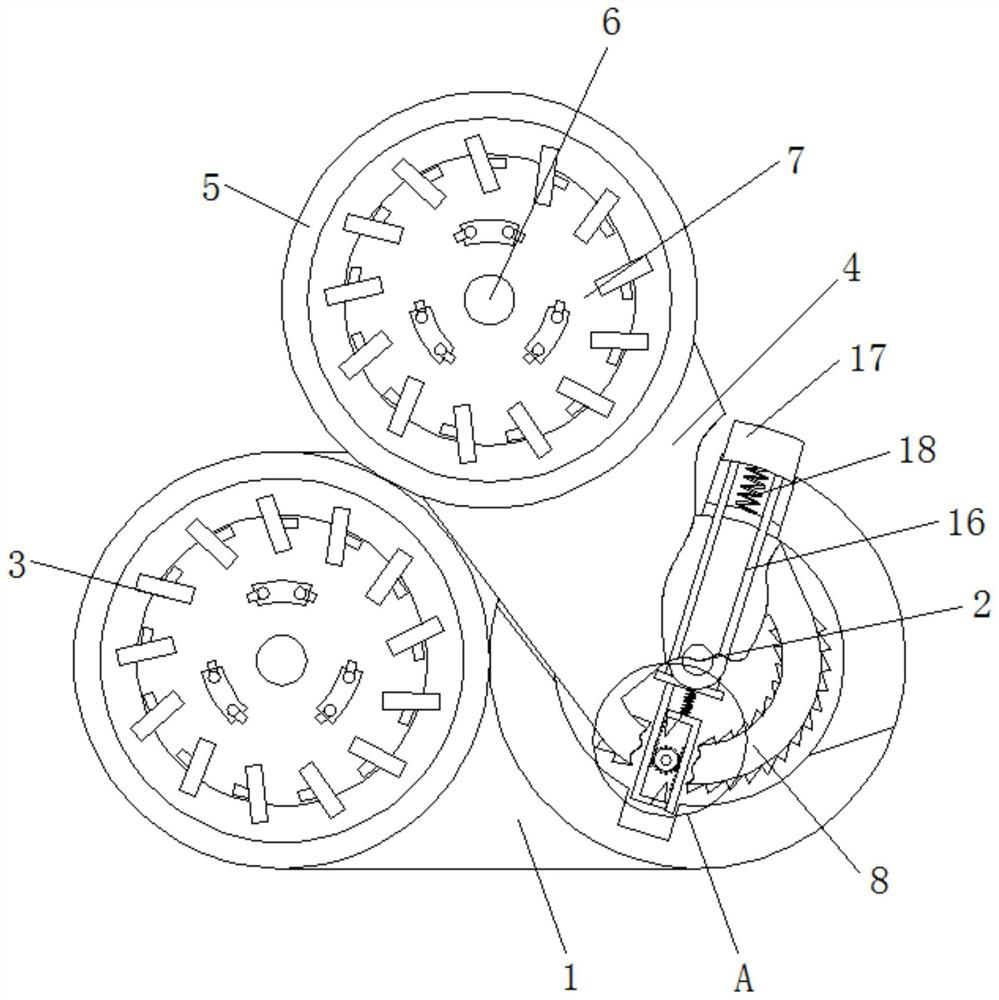

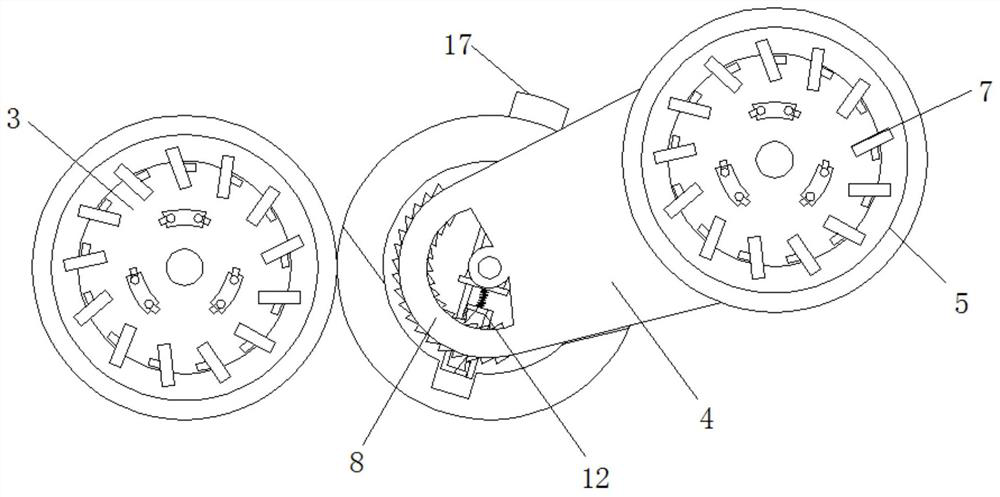

Efficient lawn mowing equipment

InactiveCN105532167ASimple structureAdjust the distance at willLawn-mowersGear wheelAgricultural engineering

Efficient lawn mowing equipment comprises a support plate, a frame body, a blade device, a first roller device, a second roller device, a pushing device and a counterweight device, wherein a motor, a first jacking rod, a first rotating shaft, a first gear, a first bracket and a first cross rod are arranged on the frame body; the blade device comprises a first spacing rod, a second gear, a second rotating shaft and a blade; the first roller device comprises a first support block, a first roller, a first positioning rod, a second jacking rod, a first spring, a third jacking rod and a first rotating part; the second roller device comprises a second support block, a second roller, a second cross rod, a second positioning rod, a fourth jacking rod, a second spring, a fifth jacking rod, a third cross rod and a second rotating part; the pushing device comprises a first vertical rod, a holding ring and a second bracket; the counterweight device comprises a counterweight block, a fixing rack and a fixing rod. The efficient lawn mowing equipment has the advantages that the distance between the blade and the ground can be adjusted freely, so as to remove weeds of a certain height as required, and save energy.

Owner:廖伟城

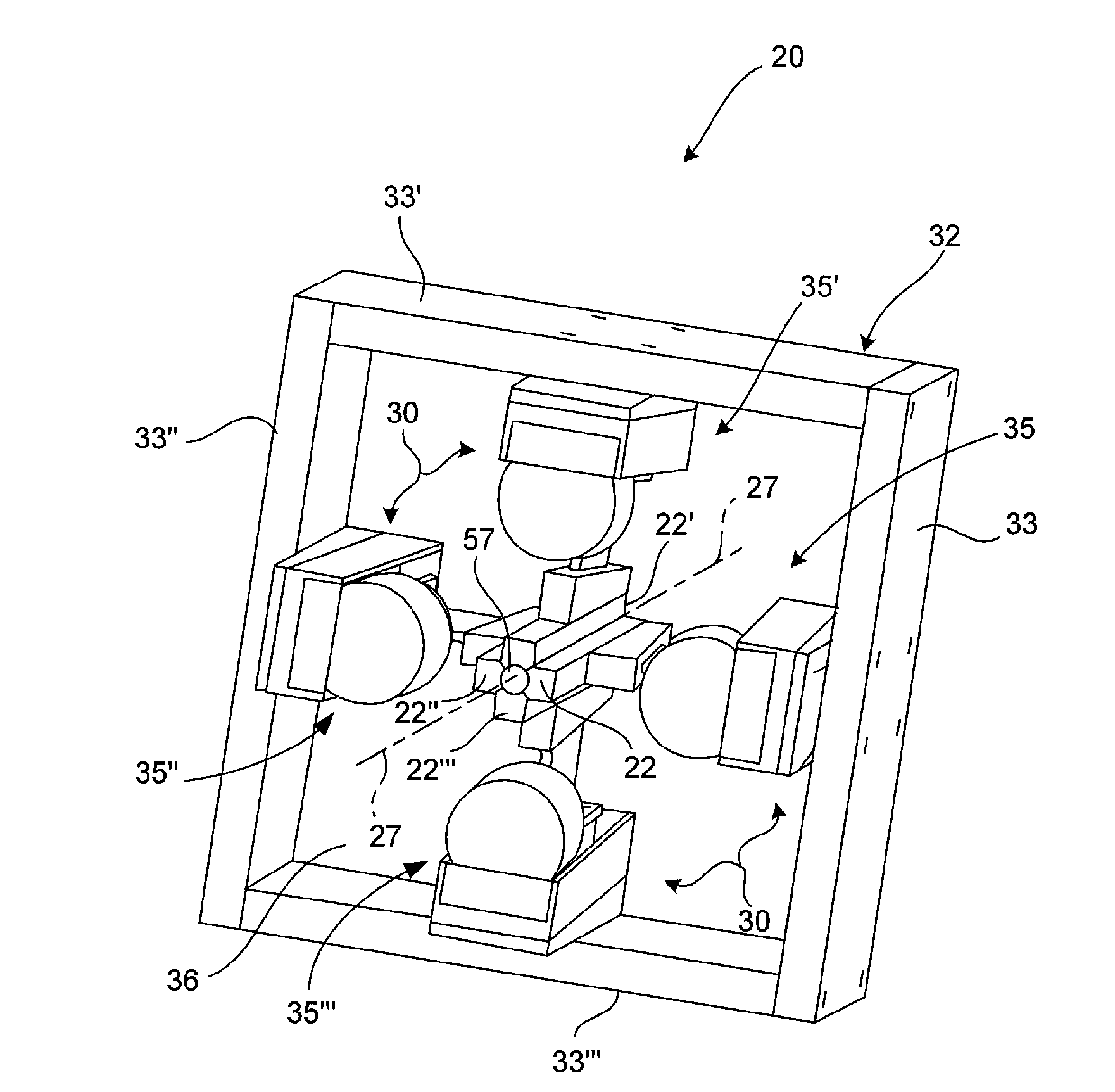

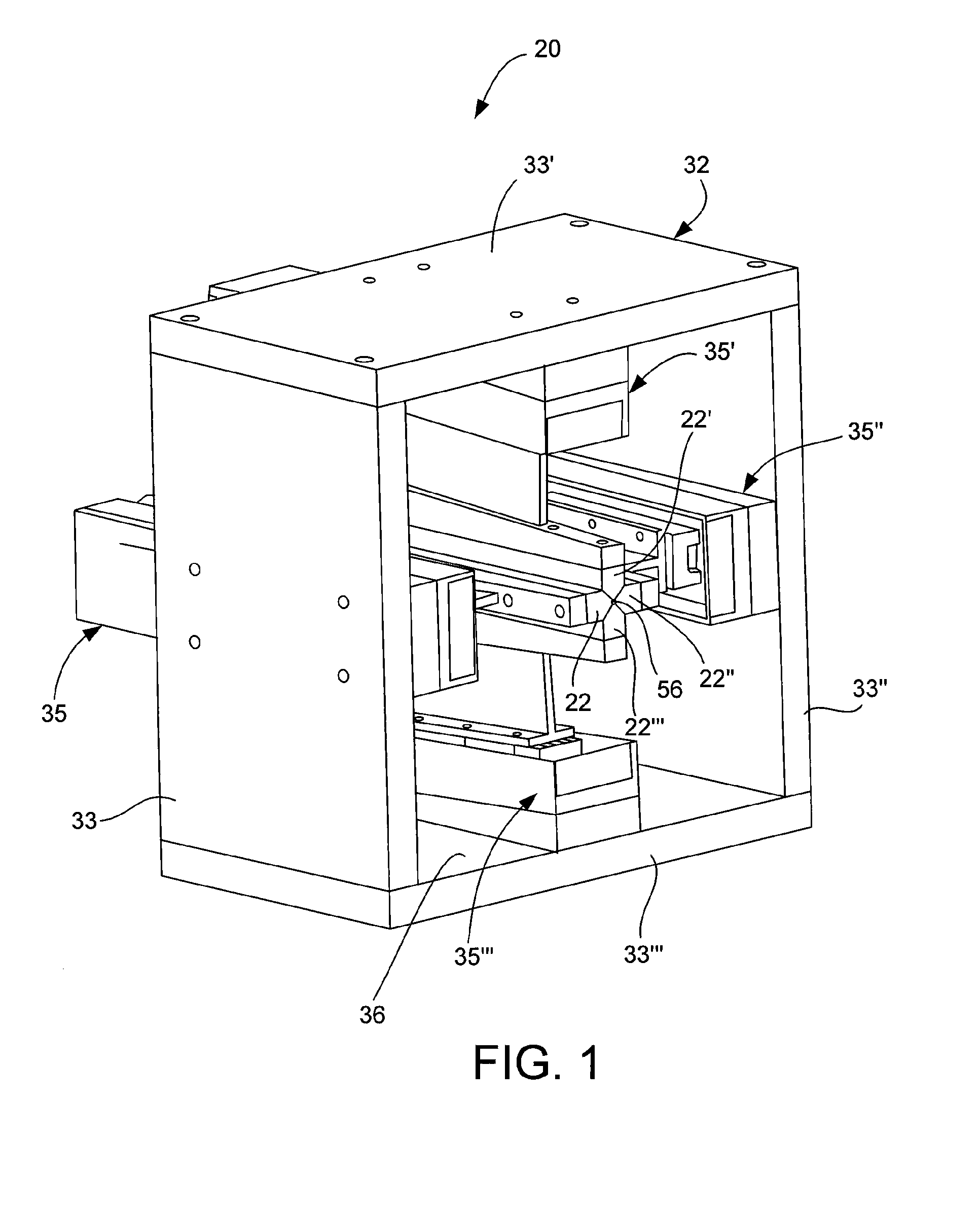

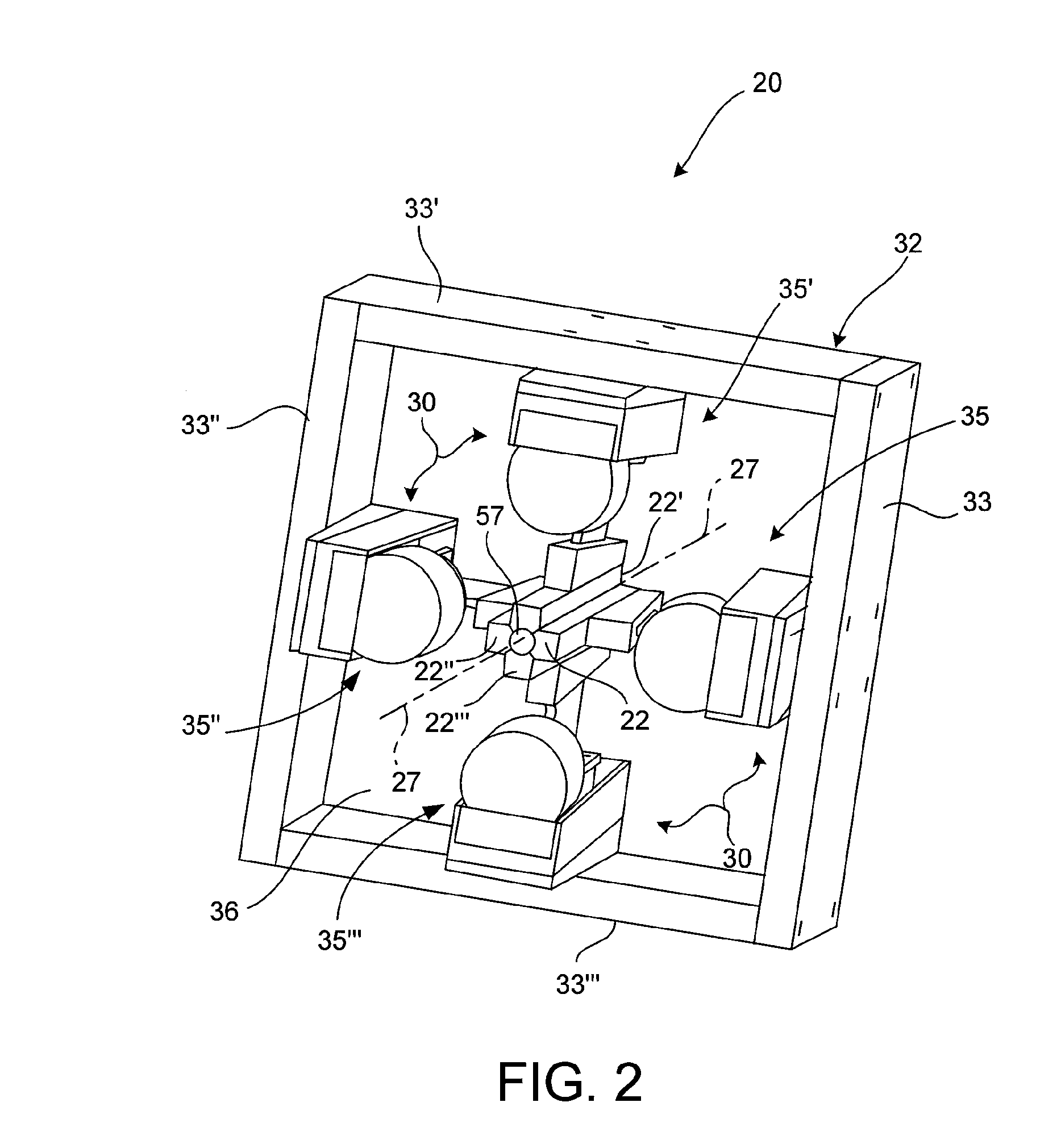

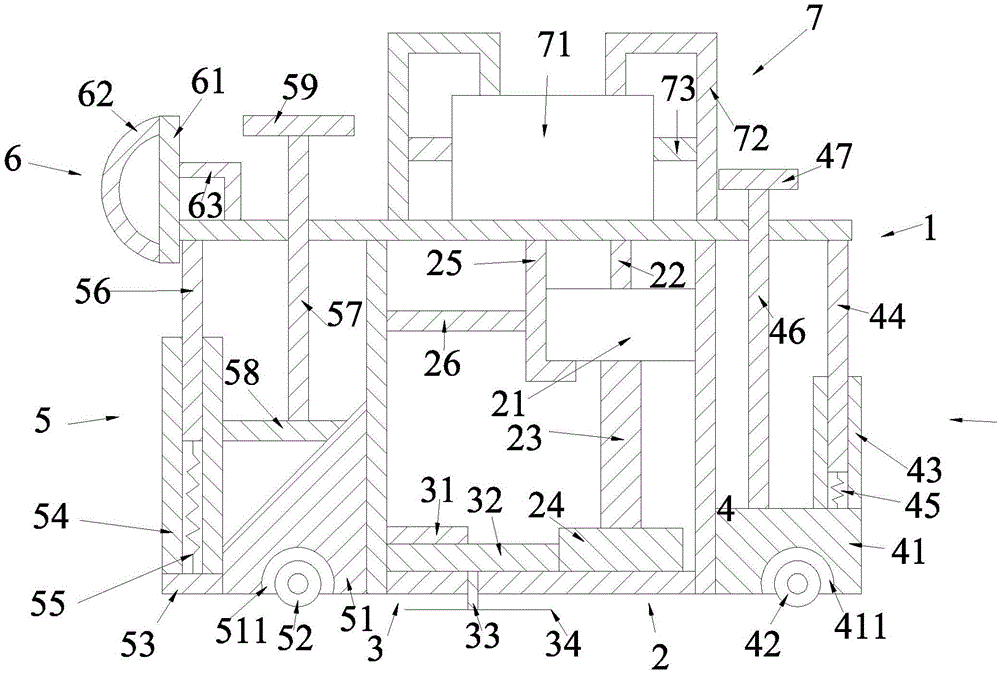

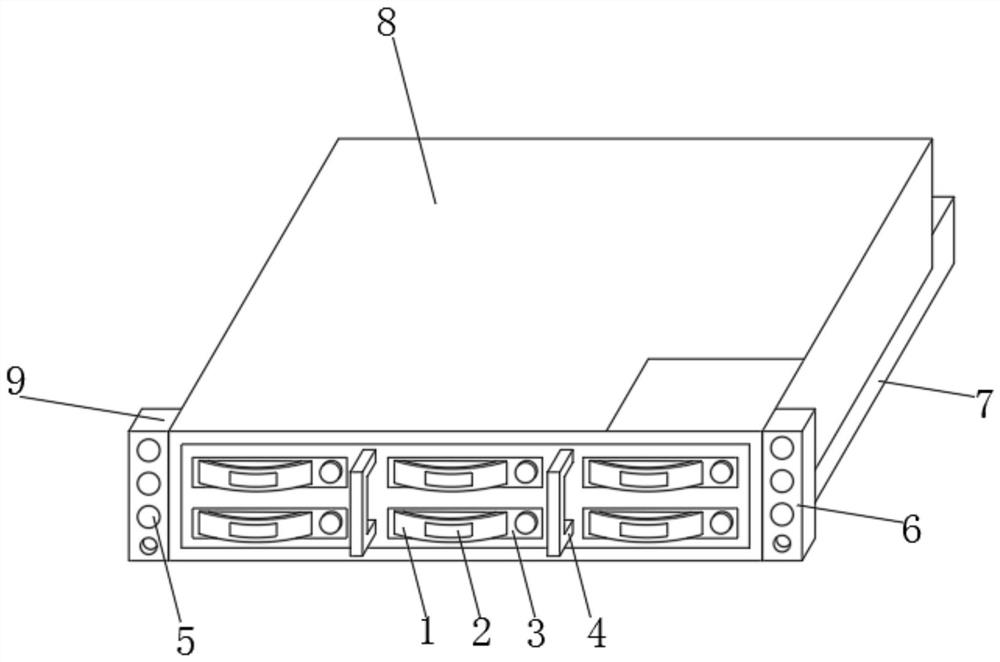

Blade device

ActiveCN102087536AImprove assembly densityImprove maintainabilityDigital data processing detailsEngineeringKnife blades

The invention relates to a blade device. The blade device comprises at least two processor cards and an interface device, wherein each processor card comprises at least one central processing unit (CPU) and a first interface; the interface device is suitable for connecting the processor cards and comprises at least one pair of second interfaces; the processor cards are connected with the second interfaces by the first interface, so that the processor cards are connected to the interface device; and each pair of second interfaces is formed on the same surface on the same side of the interface device, and horizontal space between the two second interfaces does not exceed the length of any one processor card connected with the second interfaces. In the blade device, a pair of interfaces is formed in the horizontal direction of the interface device and is used for connecting the processor cards which are overlapped in the vertical direction, and the expandability of the interface device in the horizontal direction is utilized, so the four or eight processor cards can be arranged on the same blade device, and the high packing density and serviceability of the blade device are realized.

Owner:JIANGNAN INST OF COMPUTING TECH

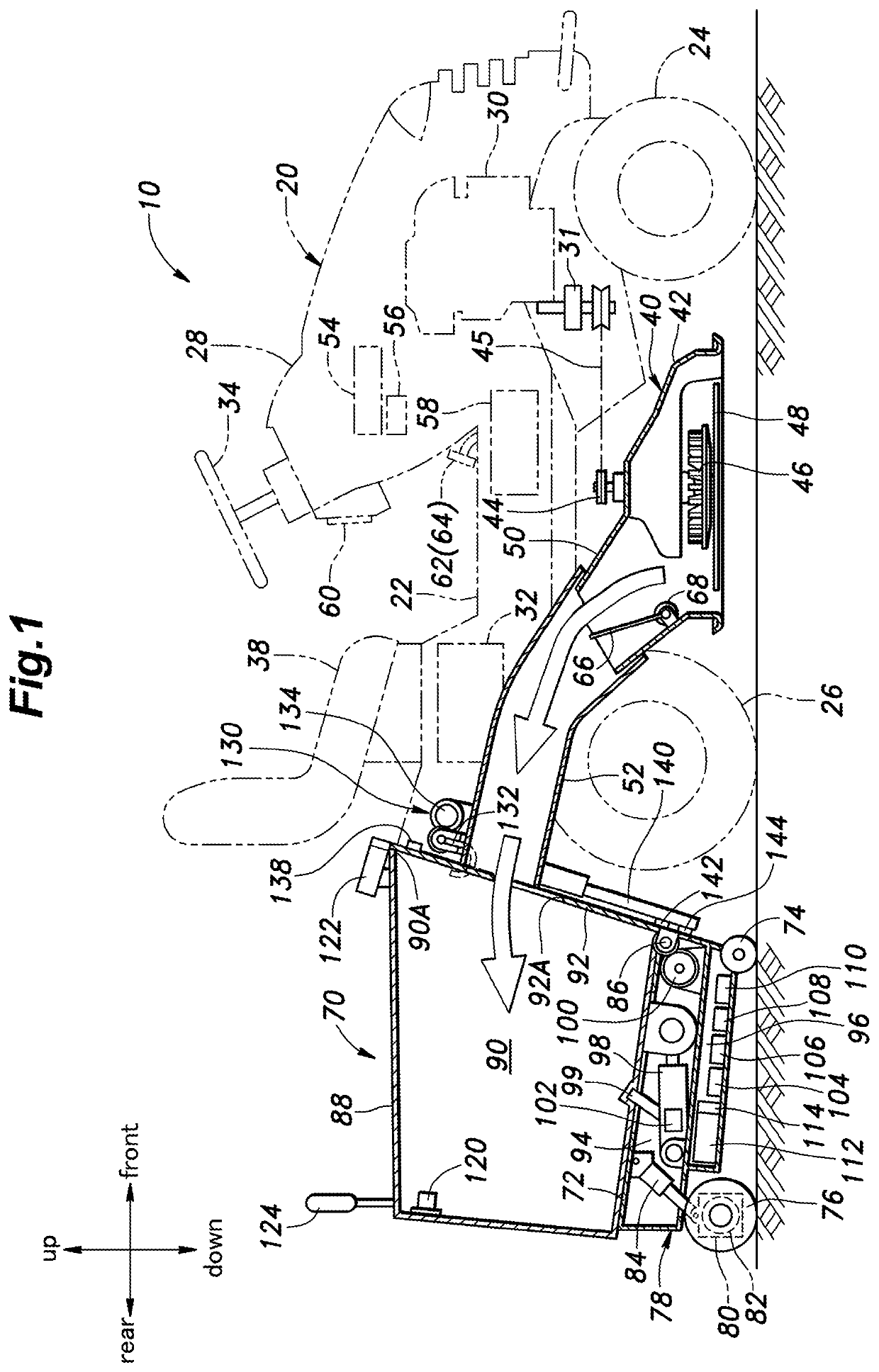

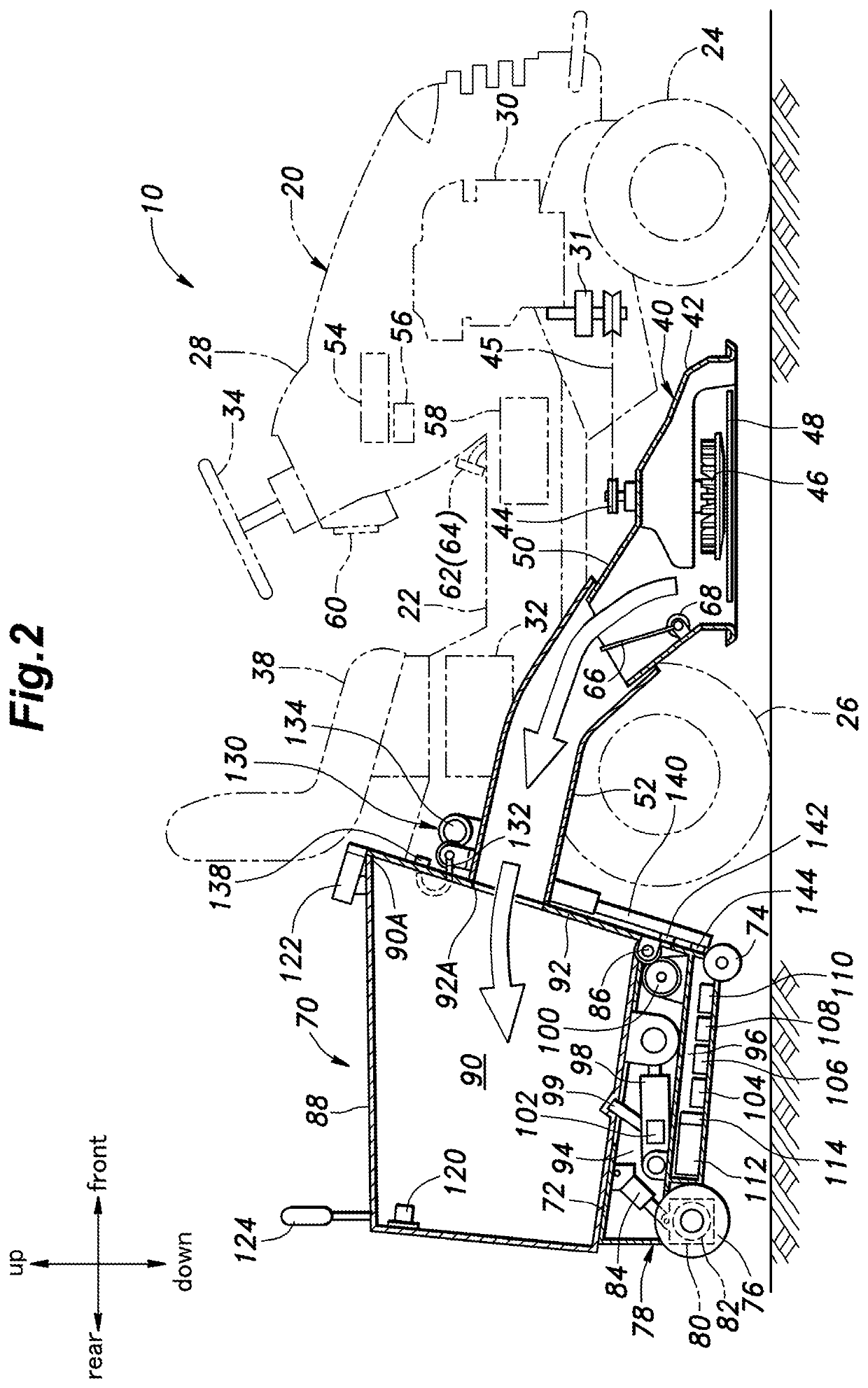

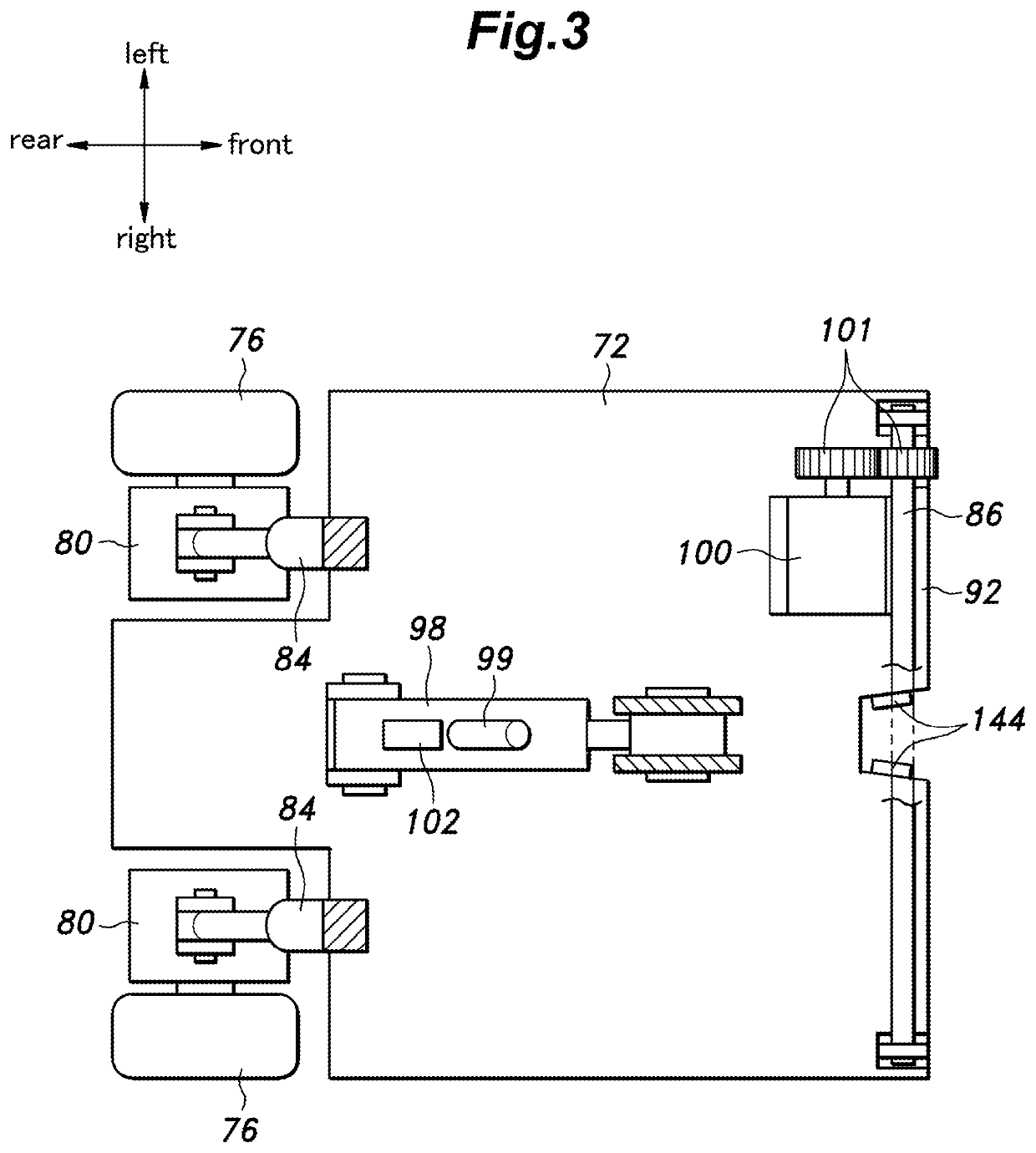

Work equipment with travel unit lifting device

ActiveUS11197422B2Energy efficiencyGuaranteed work efficiencyLawn-mowersPosition/course control in two dimensionsSimulationWork unit

Owner:HONDA MOTOR CO LTD

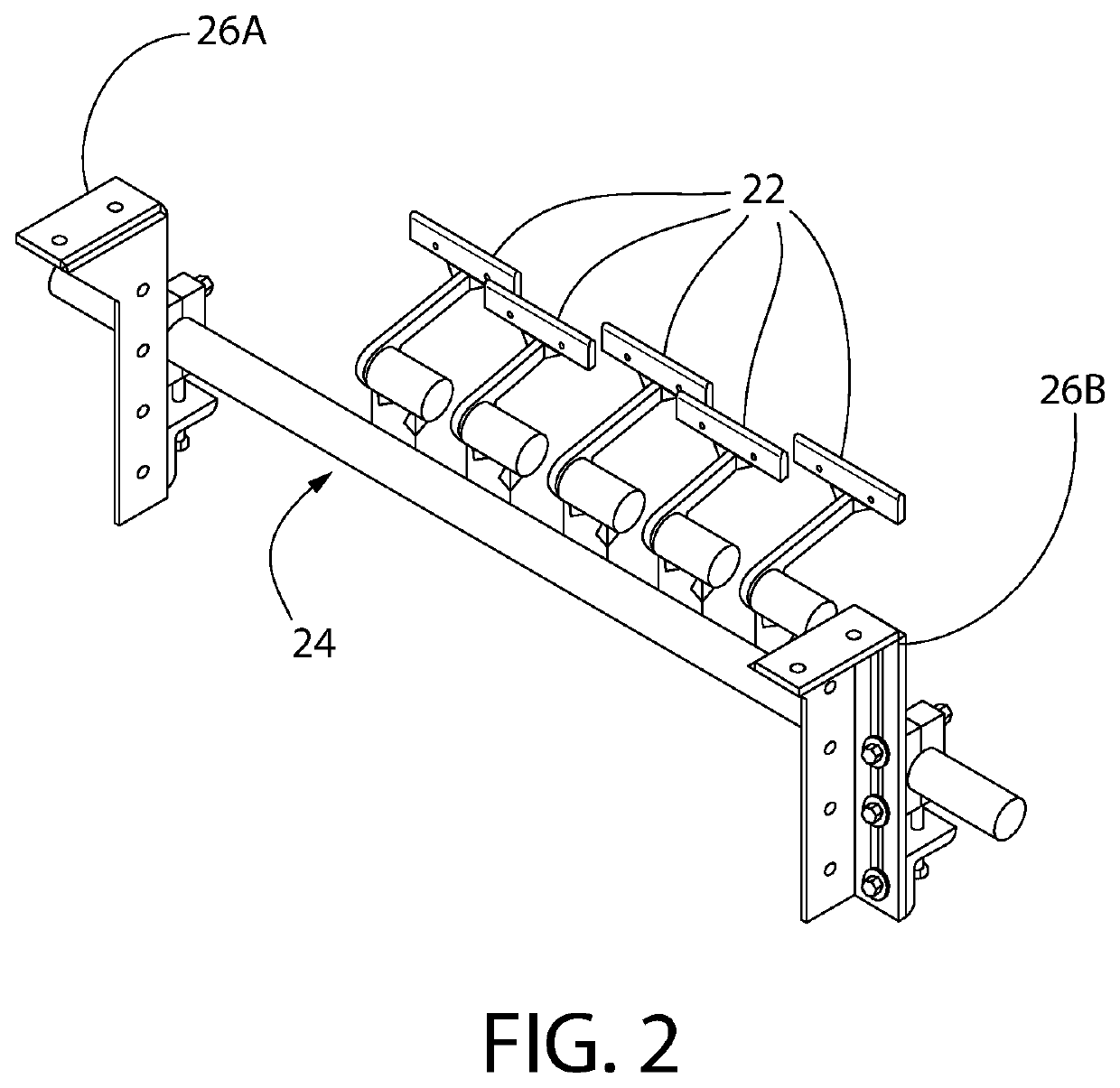

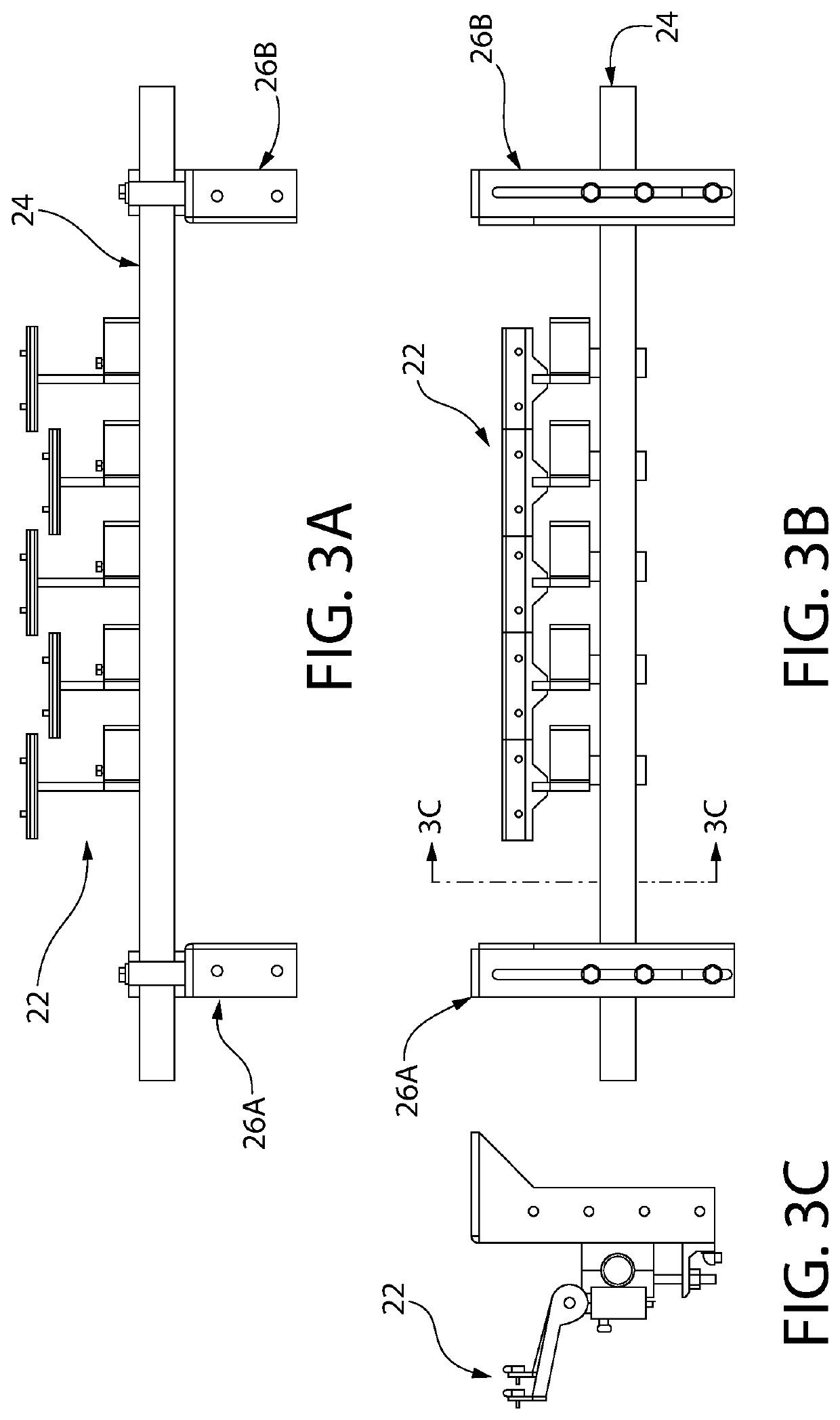

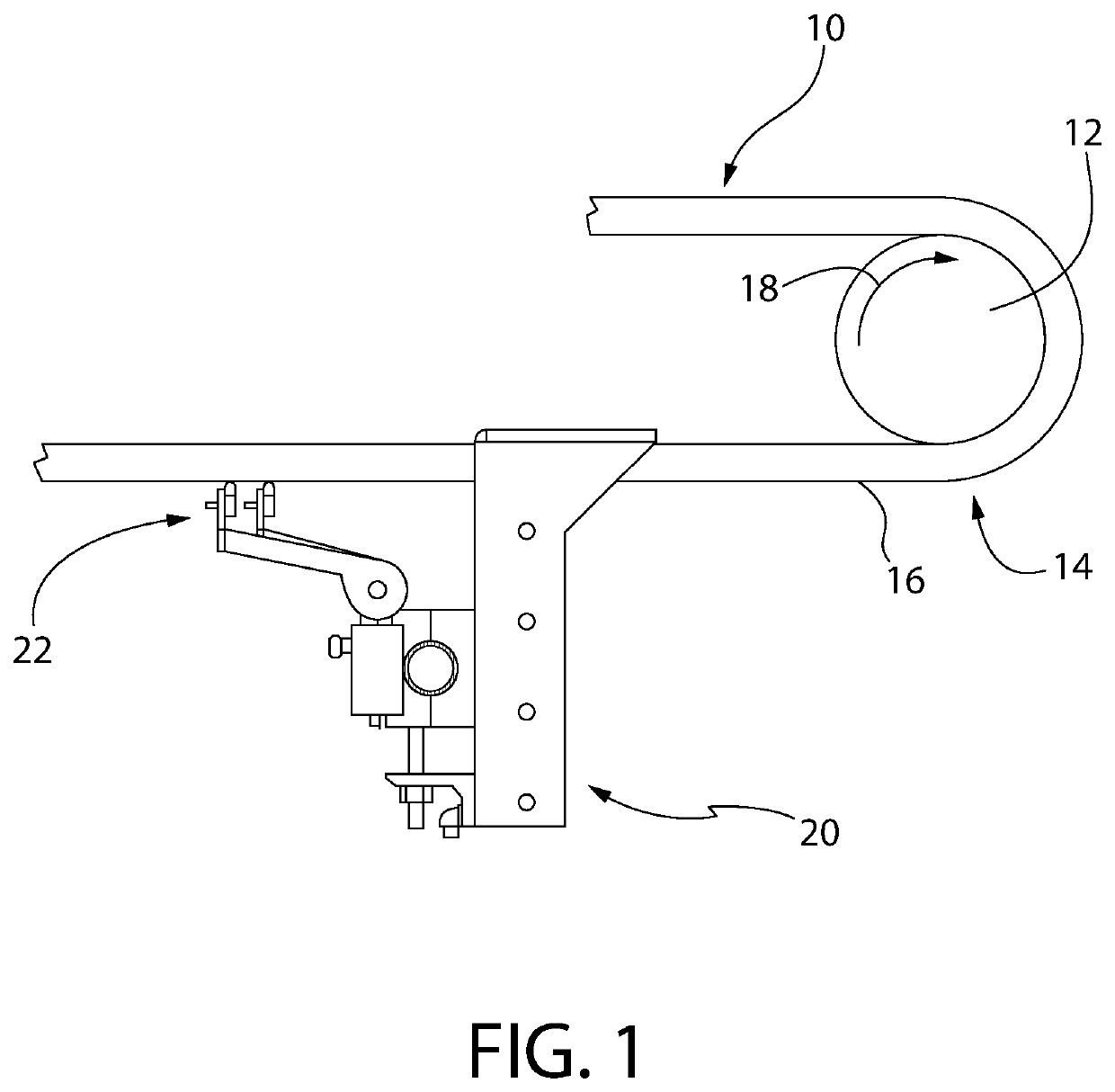

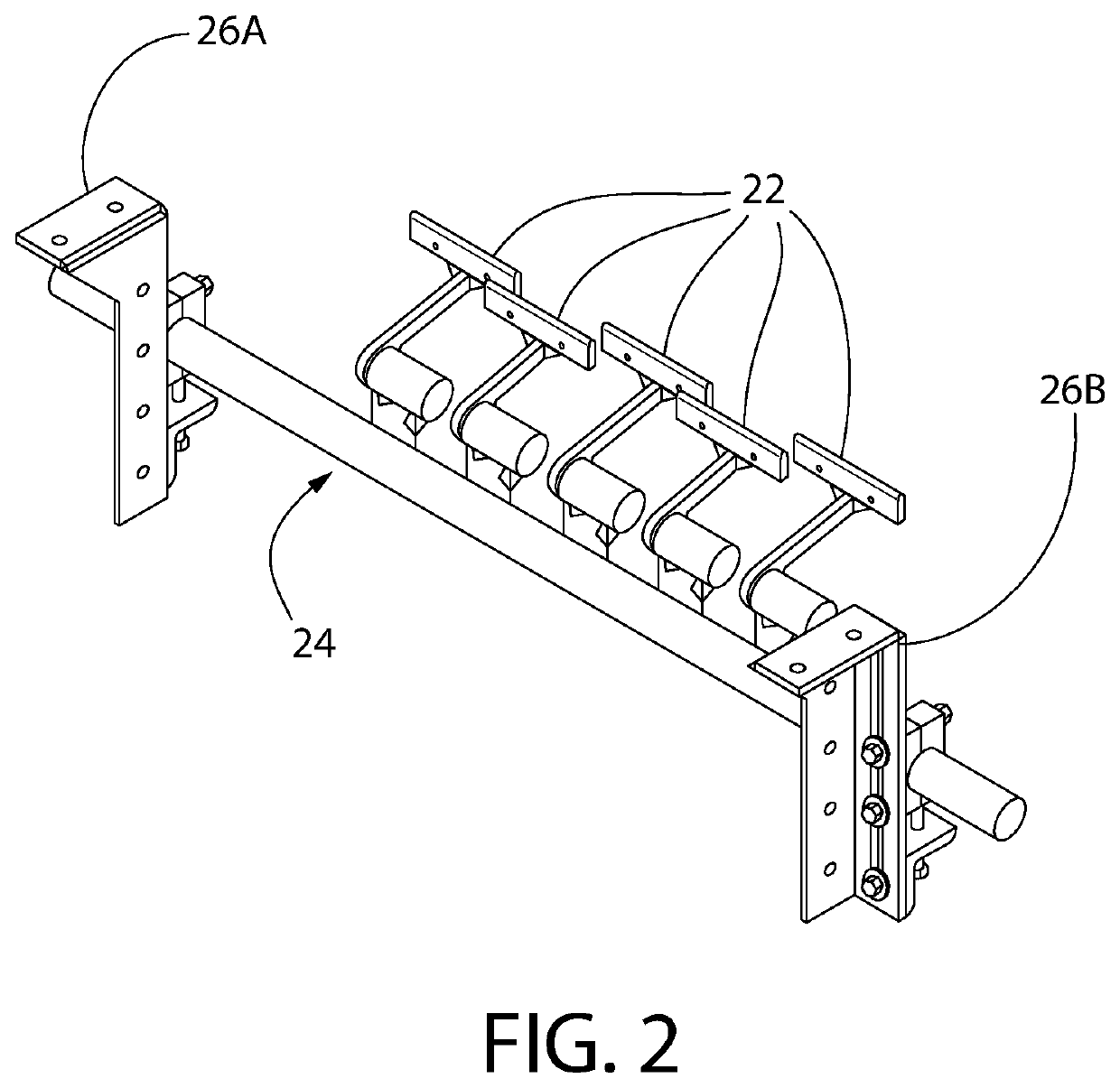

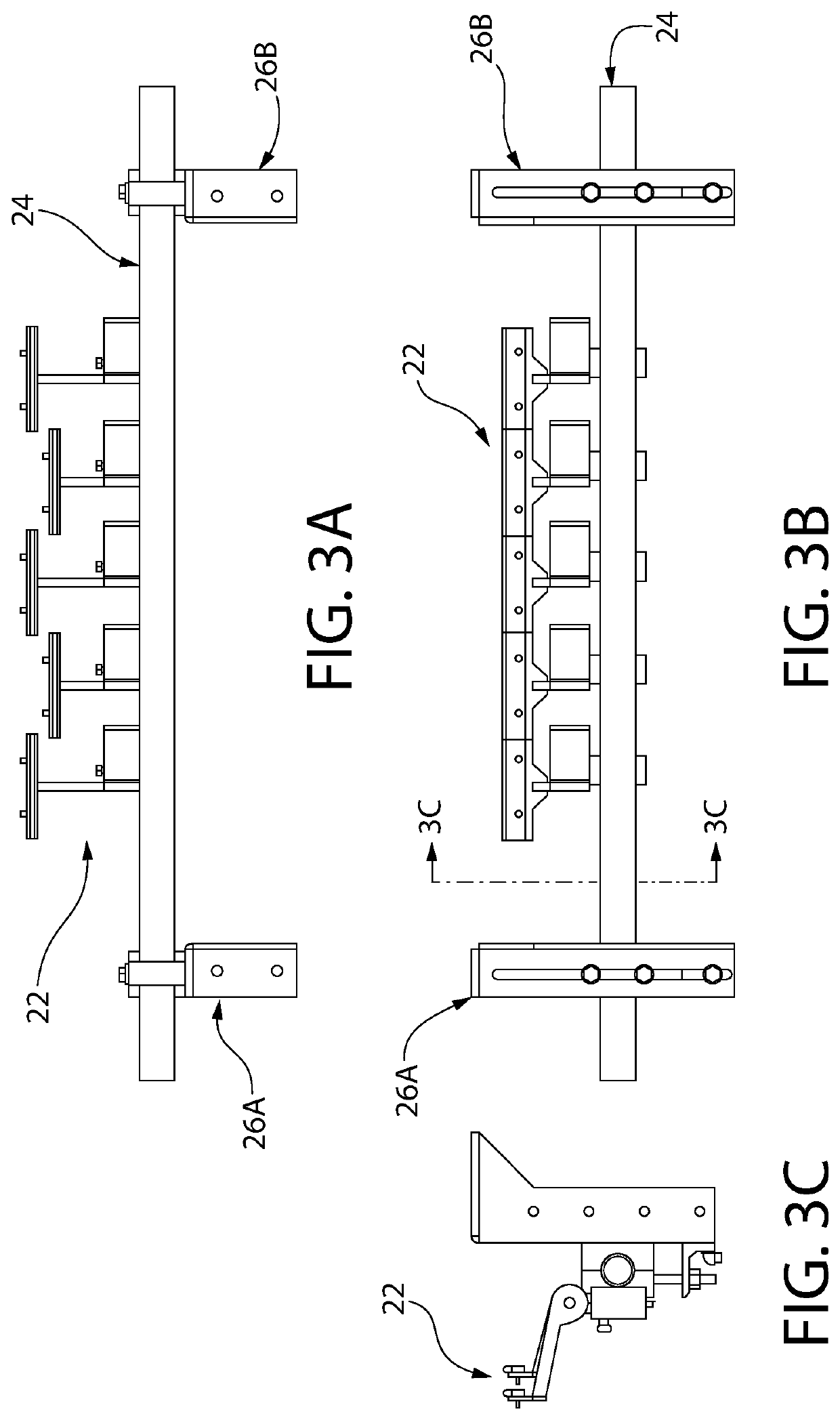

Secondary belt cleaner with modular, torsional tensioned arm and replaceable blade tips

A secondary belt cleaner system for cleaning the surface of the return side of an endless conveyor belt. The system includes a plurality of blade devices that are rotatably biased against the return side surface using a respective torsion spring therein. Each blade device includes a head portion formed by a blade support and a replaceable blade tip that is releasably secured to the blade support. The head portion is connected to one end of a blade arm and the other end of the blade arm is coupled to a rotatable shaft inside a housing that is fixedly secured to a support shaft having mounting brackets at each end for mounting the system transversely to the conveyor belt frame. Adjacent blade devices have different blade arm lengths in order to have the blade coverage overlap with no gaps in between. Because these blade arm lengths are different and to maintain each blade tip in contact with the return side surface, the respective torsion springs in adjacent blade devices are pretensioned to different angular amounts.

Owner:ASGCO MFG

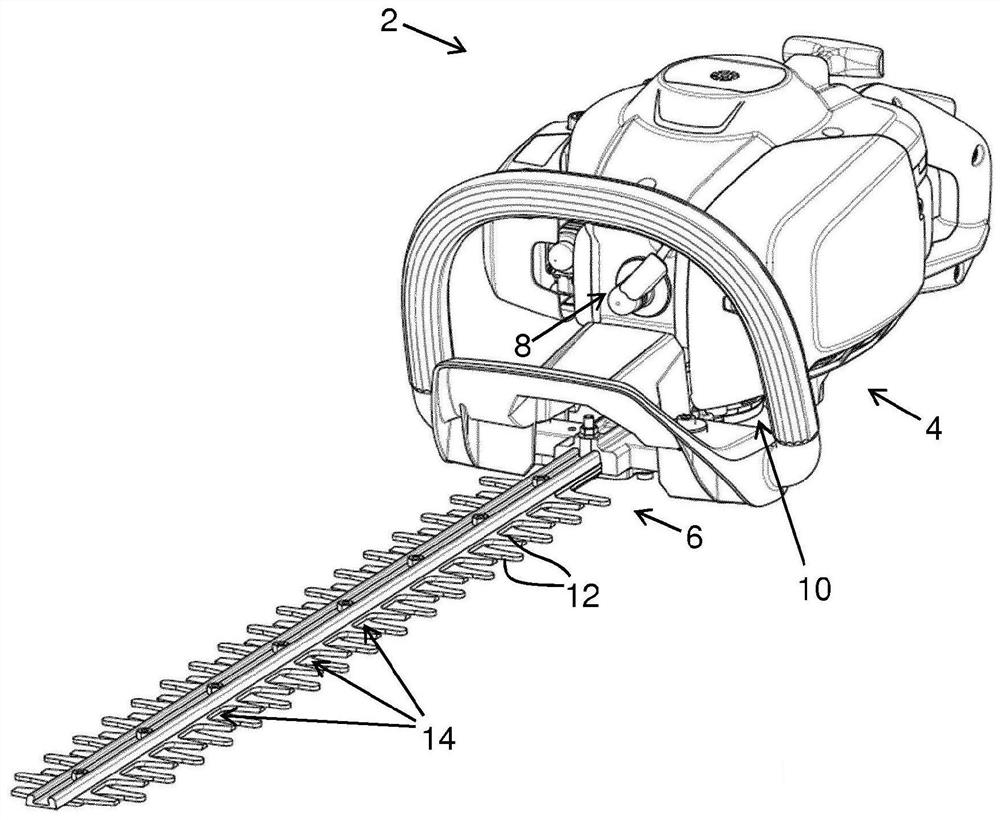

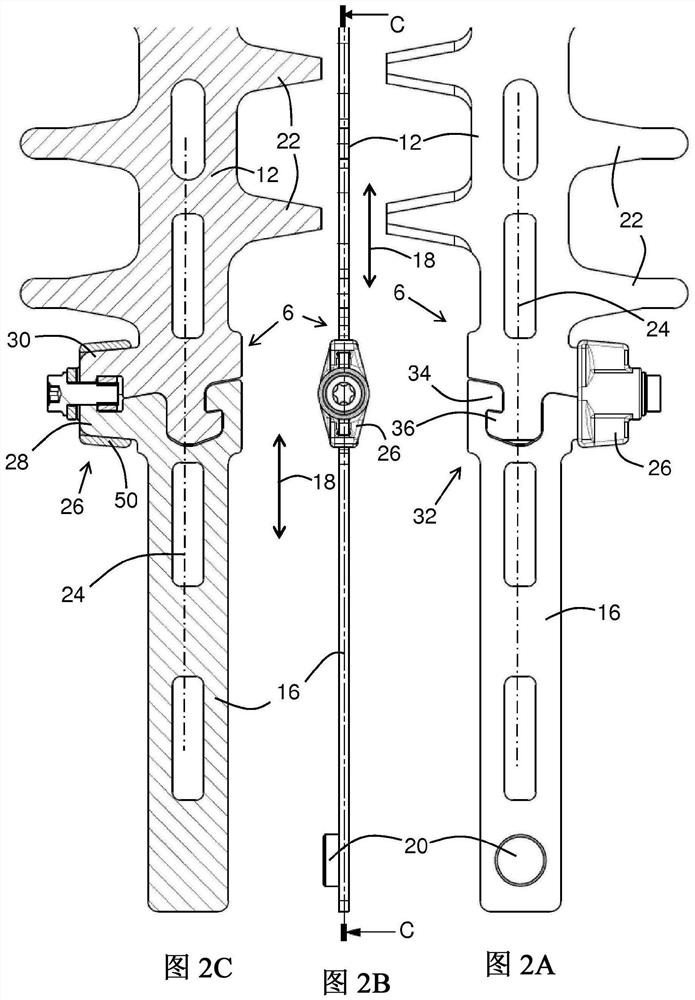

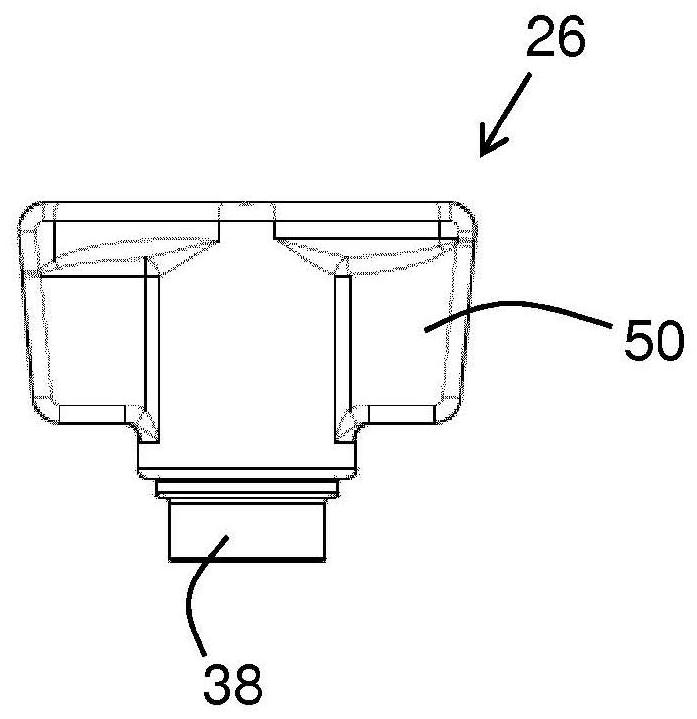

Blade arrangement and clamping member for hand-held power tools

The invention discloses a blade device (6) for a hand-held power tool (2). The blade arrangement (6) includes a drive member (16) configured to be driven to reciprocate along a drive direction (18); an elongated cutting body (12); and a clamping member (26). The clamping member (26) is configured to engage the drive member (16) and the elongated cutting body (12) to at least partially press the drive member (16) against the elongated cutting body (12) in the drive direction (18). on the cutter body (12).

Owner:HUSQVARNA AB

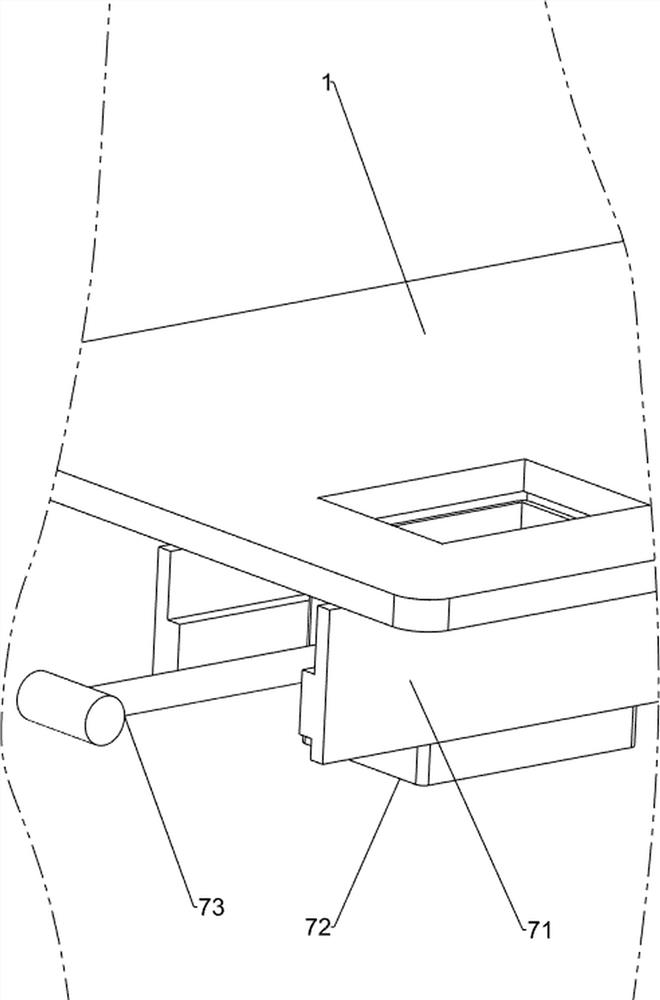

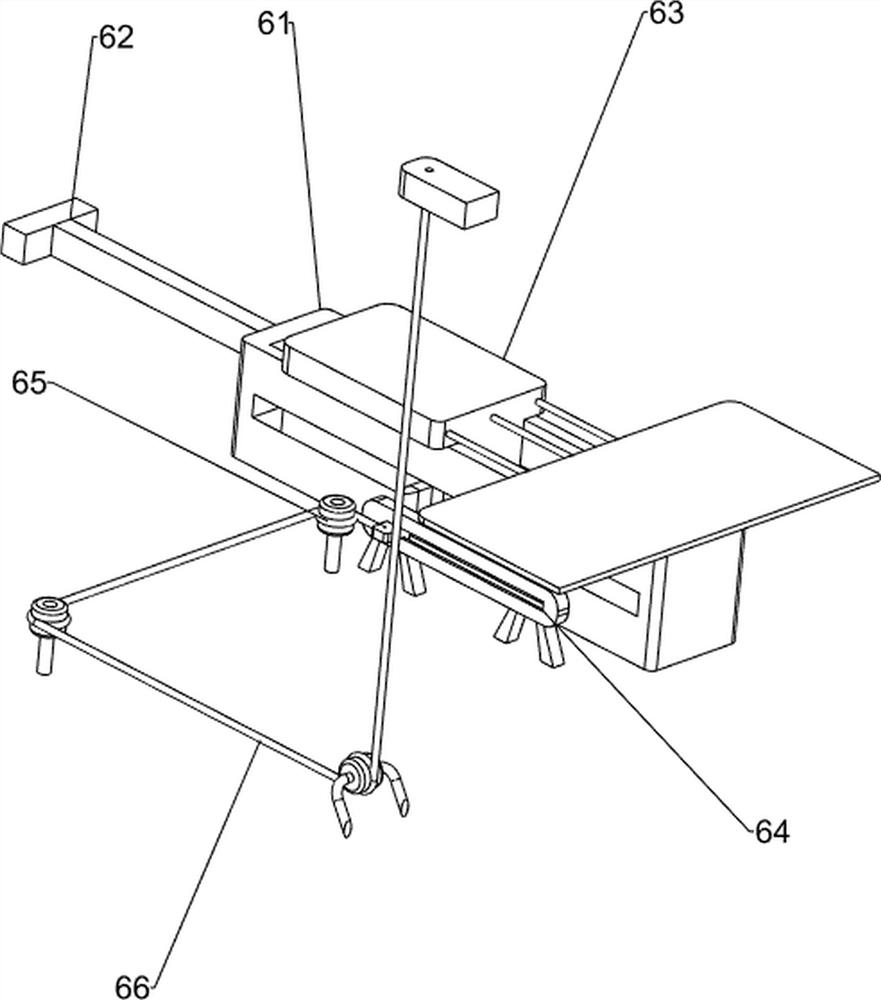

Automatic blade mounting device for art knife

ActiveCN112405420AAchieve the effect of automatic feedingAchieve the effect of being installed on the knife holderMetal-working hand toolsEngineeringKnife blades

The invention relates to an automatic blade mounting device, in particular to an automatic blade mounting device for an art knife. According to the automatic blade mounting device for the art knife, the mounting steps are simplified, and the safety and the mounting efficiency are improved. The automatic blade mounting device for the art knife comprises a workbench, a discharging mechanism, a charging mechanism, a suction mechanism and a pushing mechanism, wherein an air cylinder is mounted at the top of the workbench; the top of the workbench is provided with the discharging mechanism used forcontaining a knife sleeve; the charging mechanism is arranged at the top of the workbench, and the charging mechanism is connected with the discharging mechanism; the suction mechanism is arranged atthe top of the workbench; and the pushing mechanism is arranged at the top of the workbench, and the pushing mechanism is connected with the discharging mechanism. According to the device, a second wedge-shaped rod moves downwards to be in contact fit with a first wedge-shaped block, so that the second wedge-shaped rod slides towards the outer side, and the effect of automatic discharging of theknife sleeve is achieved.

Owner:苏州上弓刀片有限公司

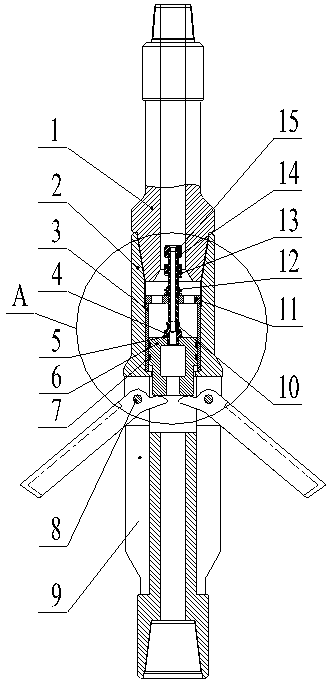

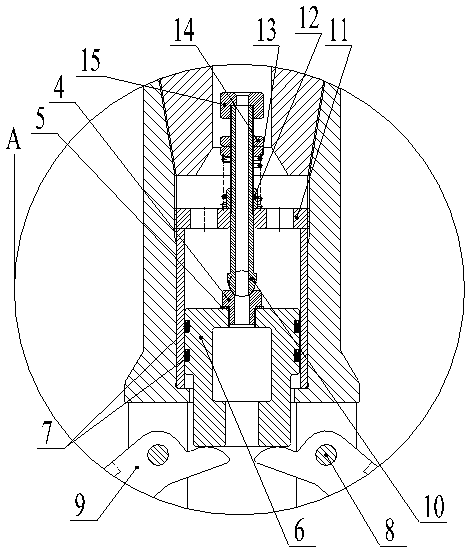

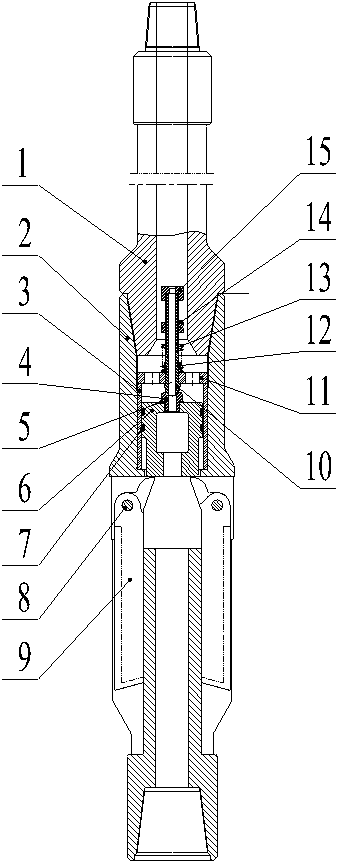

Novel deepwater large-diameter hydraulic cutting knife and efficient blade device

PendingCN107701136AIncrease the number ofReduce feverBorehole/well accessoriesStructural engineeringAlloy

The invention discloses a novel deepwater large-diameter hydraulic cutting knife and efficient blade device which comprises cutting knife blades. A filing discharging groove is longitudinally formed in the middle of the outer side of each cutting knife blade, and a first alloy filing cutting edge is fixed to the side surface of the outer side located on the left side or the right side of each filing discharging groove. A second alloy filing cutting edge is fixed to the side surface of the right side or the left side of each cutting knife blade, and the first alloy filing cutting edges and thesecond alloy filing cutting edges are located on the same side of the filing discharging grooves. According to the novel deepwater large-diameter hydraulic cutting knife and efficient blade device, metal filings generated when the first alloy filing cutting edges cut sleeves can be discharged through the filing discharging grooves, thus the current condition that in the prior art, cutting knife blades and filing cutting edges are arranged in a one-to-one correspondence mode is changed, the number of the filing cutting edges is increased, and the cutting efficiency of the novel deepwater large-diameter hydraulic cutting knife and efficient blade device is improved.

Owner:深圳市远东石油钻采工程有限公司 +2

Rotary cutting machine

InactiveCN114102703AExpand coverageImprove convenienceMetal working apparatusMachine partsEngineering

The invention discloses a rotary cutting machine in the technical field of cutting machines, which comprises a base, a mounting seat and a clamp, the mounting seat is mounted on the front side wall of the top of the base, a mounting frame is mounted on the top wall of a support, cutting equipment is mounted on the front side wall of the mounting frame, and a connecting disc is mounted on an output shaft on the right side of the cutting equipment. According to the device, cutting equipment rotates, so that a support rotates above a supporting seat, a rotating rod rotates in an inner cavity of a hole, a pull rope is wound around the outer wall of the rotating rod, a pressing plate is driven to move upwards, a touch switch below a supporting block is pressed, an electromagnet is powered on to be attracted to a magnetic block, and the blade is driven to rotate through the rotating rod; the magnetic block is completely moved into the inner cavity of the placing groove, so that the stopping block is blocked and disappears, and when the connecting disc drives the blade to rotate, the coverage range of the blade is enlarged, it is ensured that the rotating blade can still cut a machined part, the machined part does not need to be moved again, and the use convenience of the cutting machine is improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Cutting tool

ActiveCN111604945AConstant or increasing spacingReduced functional reliabilityMetal working apparatusParticle flowInterior space

The invention relates to a cutting tool (10), comprising a housing and a blade device (16); the blade device includes a blade (23) having at least one cutting edge (35), wherein the blade device (16)and / or the blade protection device can move between at least one rest position and at least one operating position relative to the housing, wherein the housing has at least one opening (22, 24). The present invention is characterized in that the particle flow cross-section of the housing remains substantially constant or increases in the particle (34) flow direction; the particle flow direction isfrom the particle (34) on one end region (18) of the housing into the inlet region (36) in the internal space (25) to the outlet region (37) of the particle (34).

Owner:MARTOR

A utility knife automatic installation blade device

ActiveCN112405420BAchieve the effect of automatic feedingAchieve the effect of being installed on the knife holderMetal-working hand toolsStructural engineeringKnife blades

The invention relates to an automatic blade installation device, in particular to a utility knife automatic blade installation device. The invention provides an automatic blade installation device for utility knives which simplifies installation steps, improves safety and improves installation efficiency. An automatic blade installation device for utility knives, comprising: a workbench, a cylinder is installed on the top of the workbench; a feeding mechanism, a feeding mechanism for placing a knife sleeve is provided on the top of the workbench; a loading mechanism, a charging mechanism is provided on the top of the workbench The feeding mechanism is connected with the unloading mechanism; the suction mechanism is provided with a suction mechanism on the top of the worktable; the pushing mechanism is provided with a pushing mechanism on the top of the worktable, and the pushing mechanism is connected with the unloading mechanism. In the present invention, the second wedge-shaped rod is moved down to contact and cooperate with the first wedge-shaped block, so that the second wedge-shaped rod slides to the outside, so as to achieve the effect of automatic cutting of the knife sleeve.

Owner:苏州上弓刀片有限公司

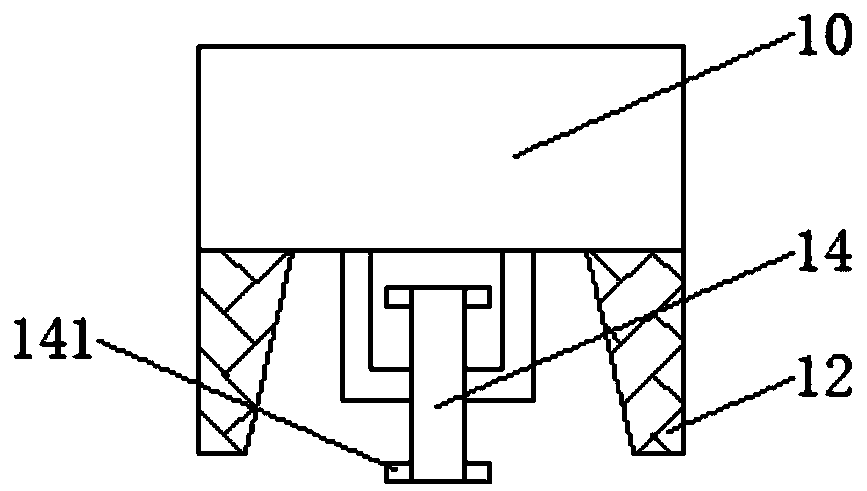

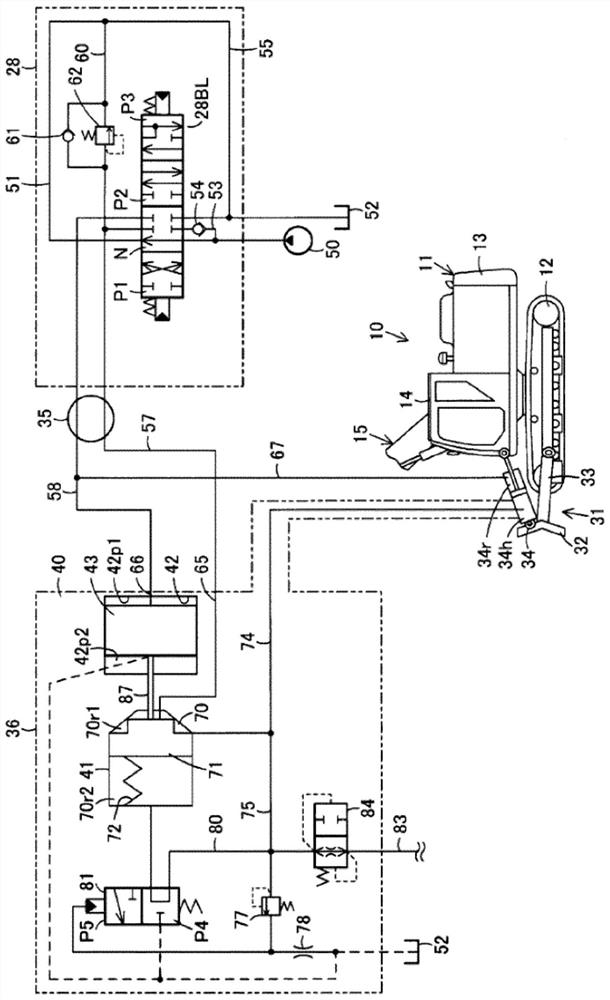

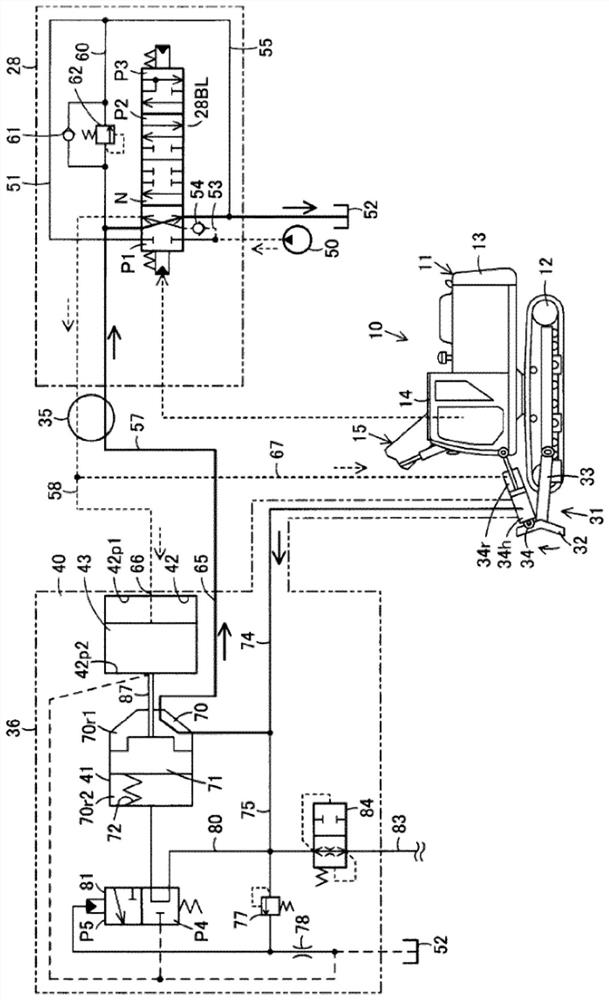

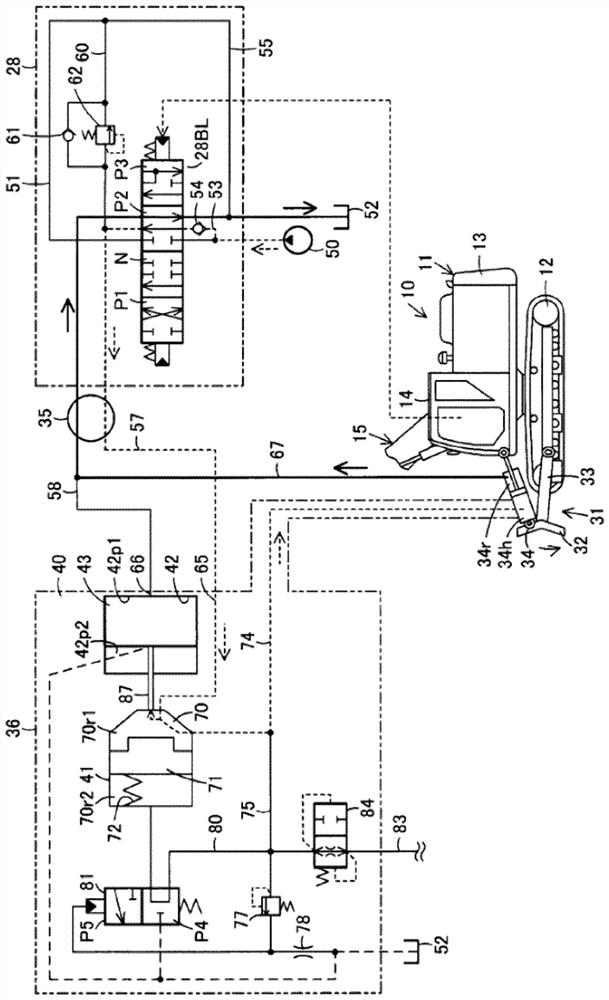

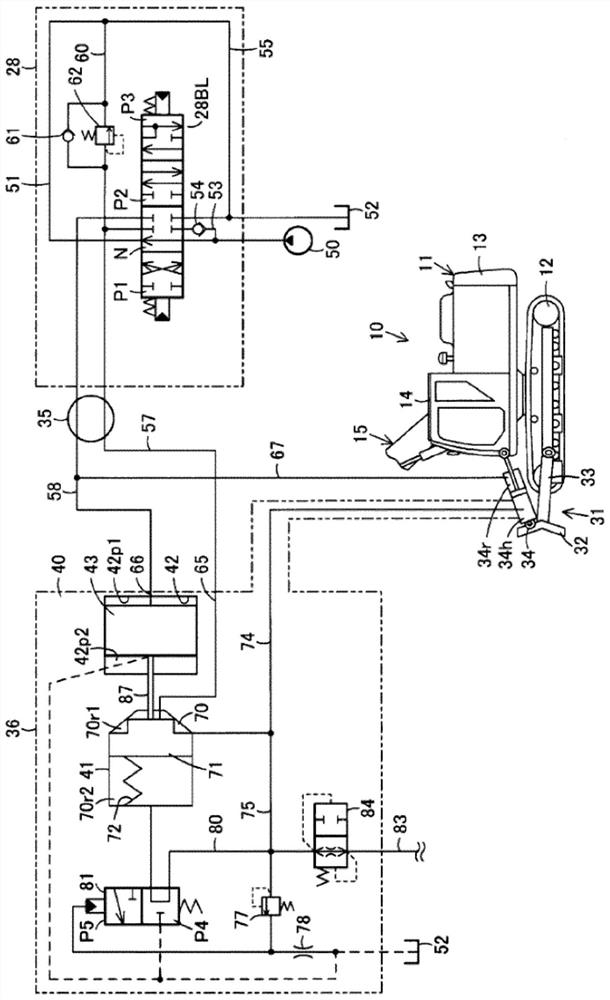

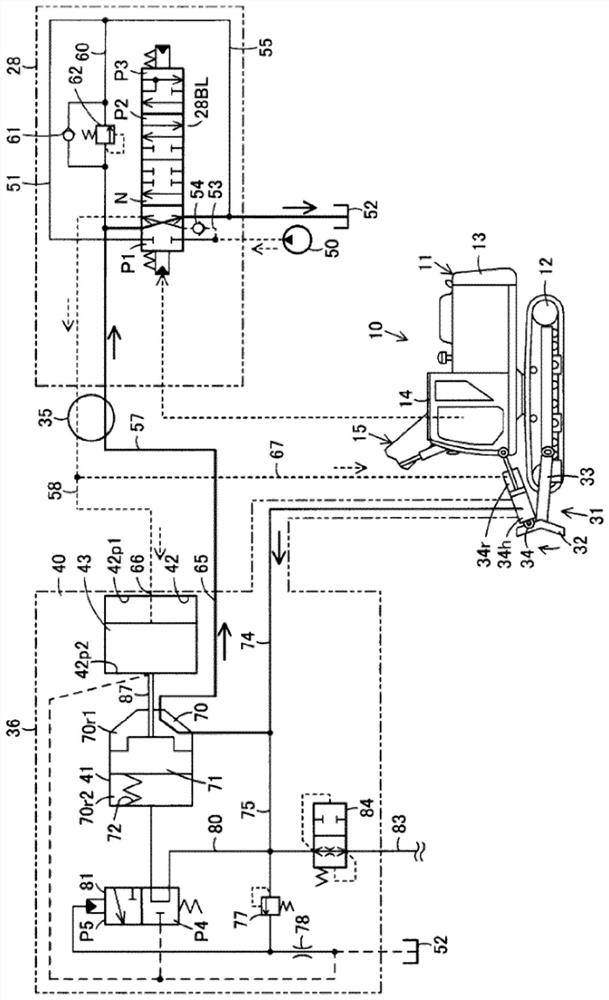

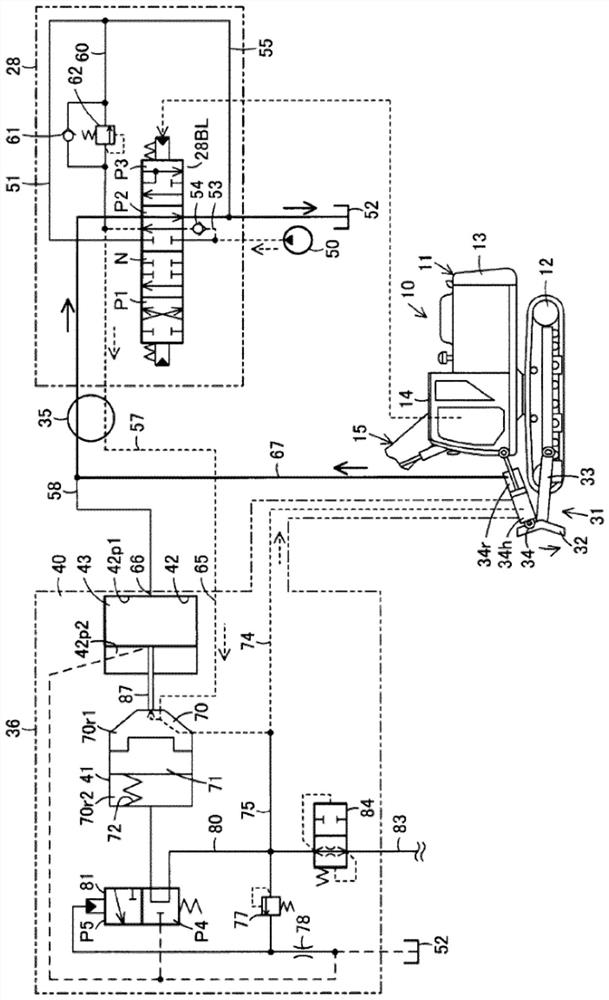

Anti-drift valve devices, blade devices and working machinery

ActiveCN112867828BAvoid driftingAvoid dischargeServomotor componentsAccumulator installationsFuel tankEngineering

Provided are an anti-drift valve device, a blade device, and a working machine capable of operating an actuating unit with a simple structure and preventing a body from drifting. The anti-drift valve device is provided with a one-way valve 41 that allows hydraulic oil to flow from the control valve 28 to the head chamber 34h of the blade cylinder 34 and prevents the flow of hydraulic oil in the opposite direction; and accommodation with the one-way valve 41 The piston receiving portion 42 provided separately from the portion 70 is configured to movably accommodate the power piston 43 . The power piston 43 defines a first piston chamber 42pl which communicates with the rod chamber 34r of the blade cylinder 34 and a second piston chamber 42pl which is used for discharge and is positioned at the poppet valve 71 of the one-way valve 41 side and communicate with the fuel tank 52. The power piston 43 is connected to the poppet 71 of the one-way valve 41 so that the power piston 43 can be operated by the difference between the urging force of the poppet 71 of the spring 72 of the one-way valve 41 and the rod chamber pressure of the blade cylinder 34 .

Owner:CATEPILLAR SARL

Cable stripping device

PendingCN113612165APeeling operation saves labor and timeReduce volumeApparatus for removing/armouring cablesStructural engineeringKnife blades

Owner:STATE GRID CORP OF CHINA +1

Intelligent squeezing equipment based on data analysis and working method of intelligent equipment

ActiveCN110693037AEnsure safetyGuaranteed freshnessTelevision system detailsJuice extractionRotary valveEngineering

The invention discloses intelligent squeezing equipment based on data analysis and a working method of the intelligent equipment. The intelligent equipment comprises a cutting-off mechanism, a juice squeezing mechanism and a processing mechanism, wherein the processing mechanism comprises a processor, a driving device and a storing device; the cutting-off mechanism comprises a first blade device,a second blade device, a conveying platform, a sieving funnel, a squeezing device and a camera shooting device; the second blade is arranged to be a cylindrical blade; the first blade is arranged in the manner that a plurality of straight blades uniformly surround the second blade; the conveying platform is used for conveying raw materials to the sieving funnel; a plurality of discharging holes which communicate with the juice squeezing mechanism are formed in the side wall and the bottom of the sieving funnel; an opening and closing type rotating valve is arranged in each discharging hole, and is used for adjusting the hole diameter of each discharging hole; the squeezing device is used for squeezing raw materials to enable the squeezed raw materials to pass through the discharging holes;and the juice squeezing mechanism comprises an electric sealing layer, a spiral knife net and a discharging opening, wherein the electric sealing layer is used for isolating the juice squeezing mechanism and the cutting-off mechanism; the spiral knife net is used for crushing the raw materials; and the discharging opening is used for outputting a beverage.

Owner:江门市蓬江区裕威倡电器实业有限公司

A blade device with high performance and low power consumption

ActiveCN109283981BRealize switching interconnectionSolving Bandwidth LimitationsDigital processing power distributionEnergy efficient computingWorking environmentKnife blades

Owner:重庆秦嵩科技有限公司

Secondary belt cleaner with modular, torsional tensioned arm and replaceable blade tips

A secondary belt cleaner system for cleaning the surface of the return side of an endless conveyor belt. The system includes a plurality of blade devices that are rotatably biased against the return side surface using a respective torsion spring therein. Each blade device includes a head portion formed by a blade support and a replaceable blade tip that is releasably secured to the blade support. The head portion is connected to one end of a blade arm and the other end of the blade arm is coupled to a rotatable shaft inside a housing that is fixedly secured to a support shaft having mounting brackets at each end for mounting the system transversely to the conveyor belt frame. Adjacent blade devices have different blade arm lengths in order to have the blade coverage overlap with no gaps in between. Because these blade arm lengths are different and to maintain each blade tip in contact with the return side surface, the respective torsion springs in adjacent blade devices are pretensioned to different angular amounts.

Owner:ASGCO MFG

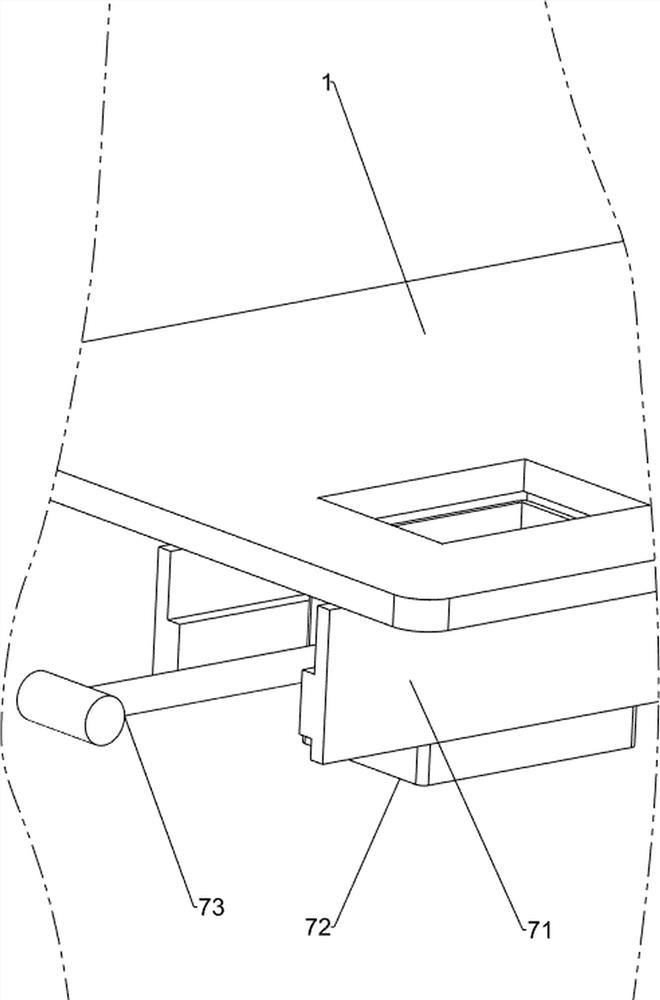

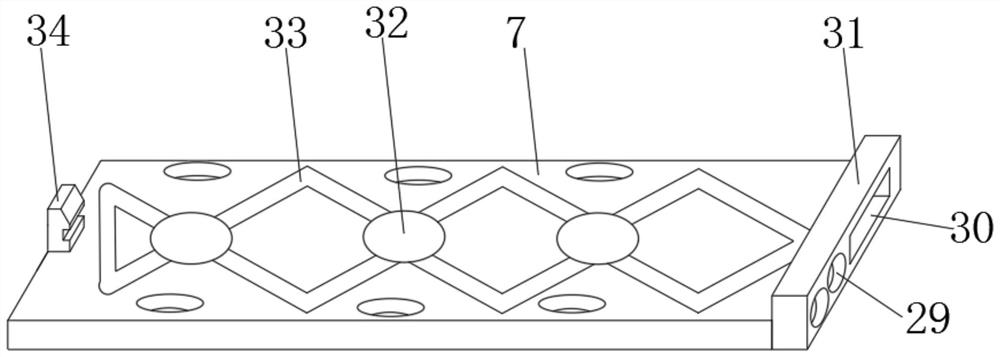

Blade taking device of blade server

InactiveCN111251066AImprove work efficiencyEasy maintenanceProtection and storage accessoriesStructural engineeringKnife blades

The invention discloses a blade taking device of a blade server. The blade taking device comprises a hydraulic box, wherein a first oil conveying pipe is arranged in the hydraulic box, a transverse plate is fixedly installed on the hydraulic box, a supporting block and two fixed shaft blocks which are symmetrical front and back are fixedly installed on the transverse plate, a long shaft is rotationally arranged between the two fixed shaft blocks, a plurality of sets of vertical supporting plates which are symmetrical front and back are fixedly installed on the long shaft, transmission cavitiesare formed in the vertical supporting plates, steering devices are arranged in the transmission cavities, and the hydraulic box is fixedly installed on the vertical supporting plates. According to the device, a blade server locking device and a blade taking device are unified, blades are automatically clamped and taken through one key, the two hands of a maintainer are liberated, then the blade server is stably taken out and steered to vacate space, the maintainer can maintain the tool server and a blade base conveniently, one-key recovery can be achieved after maintenance is completed, and the working efficiency of maintenance personnel is greatly improved.

Owner:宁波绵亘科技有限公司

An adjustable electric razor blade device using the principle of ratchet ring positioning

ActiveCN111015743BEasy to turn and adjustFlexible Adjustment StructureMetal working apparatusRatchetEngineering

Owner:义乌路豪电器有限公司

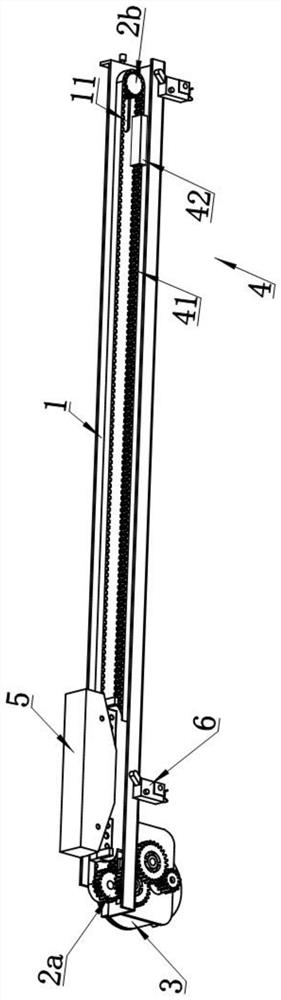

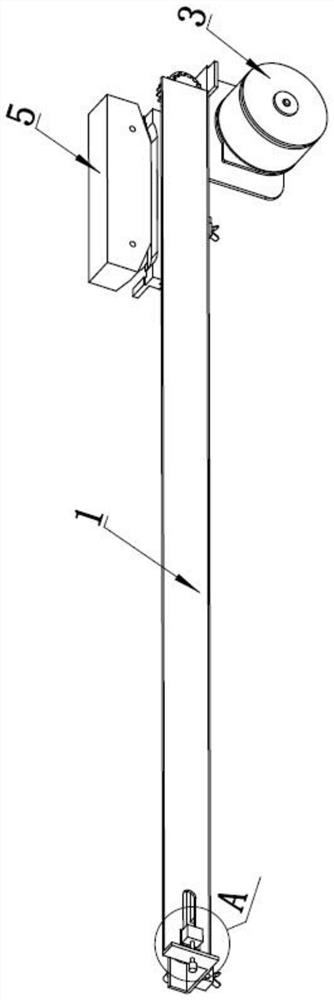

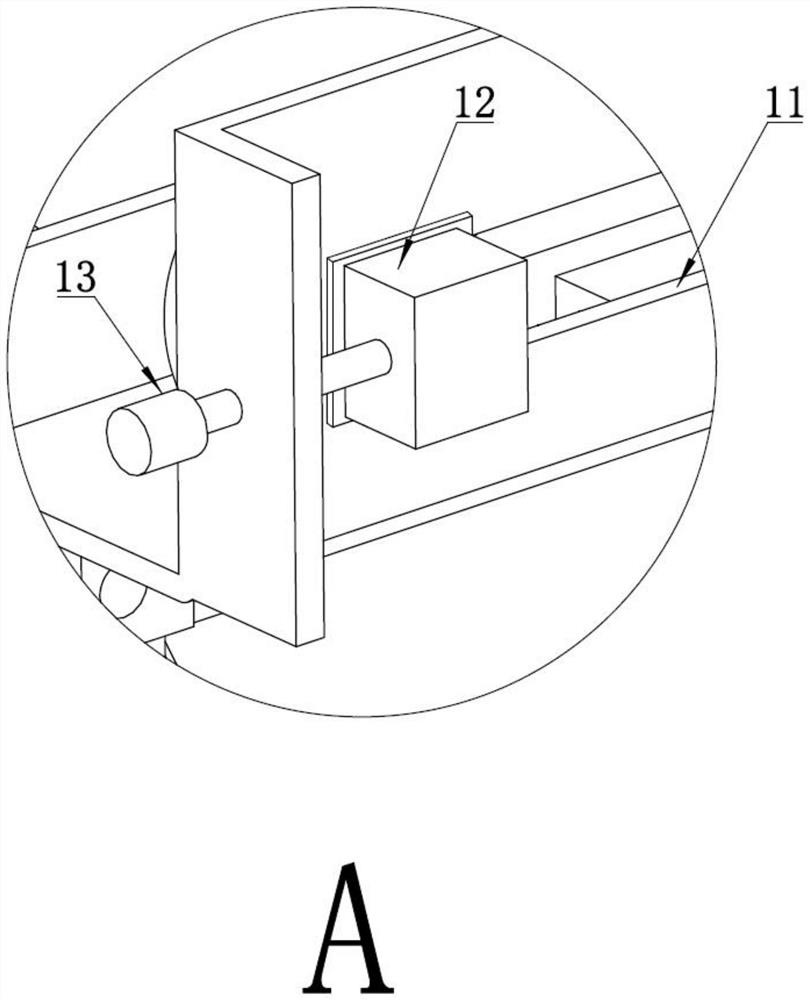

Cutter assembly suitable for different thicknesses and using method thereof

ActiveCN112606572AEasy to operateSolve the problem of large size and difficult processingOther printing apparatusGear driveGear wheel

The invention provides a cutter assembly suitable for different thicknesses. The cutter assembly comprises a base, gears are rotationally arranged at the two ends of the base separately, one of the gears is in transmission connection with a stepping driving piece, and a conveying belt assembly is arranged between the two gears in a transmission mode; the conveying belt assembly comprises a synchronous belt with two free ends and a connecting piece used for surrounding the synchronous belt, and a blade device is arranged on the synchronous belt; and when the blade device is located at the original point, the blade device is close to one gear, and the connecting piece obliquely faces the blade device and is arranged at the position close to the other gear. The cutter assembly is convenient to disassemble and assemble, can meet the requirements for full cutting, half full cutting and cutting of different paper thicknesses, and has the advantages of being diverse in function and high in practicability.

Owner:XIAMEN RONGTA TECH

Drift-prevention valve device, blade device, and working machine

ActiveCN112867828AAvoid driftingAvoid dischargeServomotor componentsAccumulator installationsEngineeringMachine

To provide a drift-prevention valve device, a blade device, and a working machine capable of operating an actuated unit and preventing the machine body from drifting with a simple configuration. The drift-prevention valve device is provided with a non- return valve 41 that allows the flow of hydraulic oil from a control valve 28 to a head chamber 34h of a blade cylinder 34 and blocks the flow of the hydraulic oil in the reverse direction; and a piston accommodation part 42 separately disposed from an accommodation part 70 of the non-return valve 41, configured to movably accommodate a power piston 43. The power piston 43 defines a first piston chamber 42pl communicating with a rod chamber of 34r of the blade cylinder 34 and a second piston chamber 42p2 for drain positioned on a poppet 71 side of the non- return valve 41 and communicating with a tank 52. The power piston 43 is connected to the poppet 71 of the non-return valve 41, so that the power piston 43 can be operated by the difference between the urging force of the poppet 71 by a spring 72 of the non-retum valve 41 and a rod chamber pressure of the blade cylinder 34.

Owner:CATEPILLAR SARL

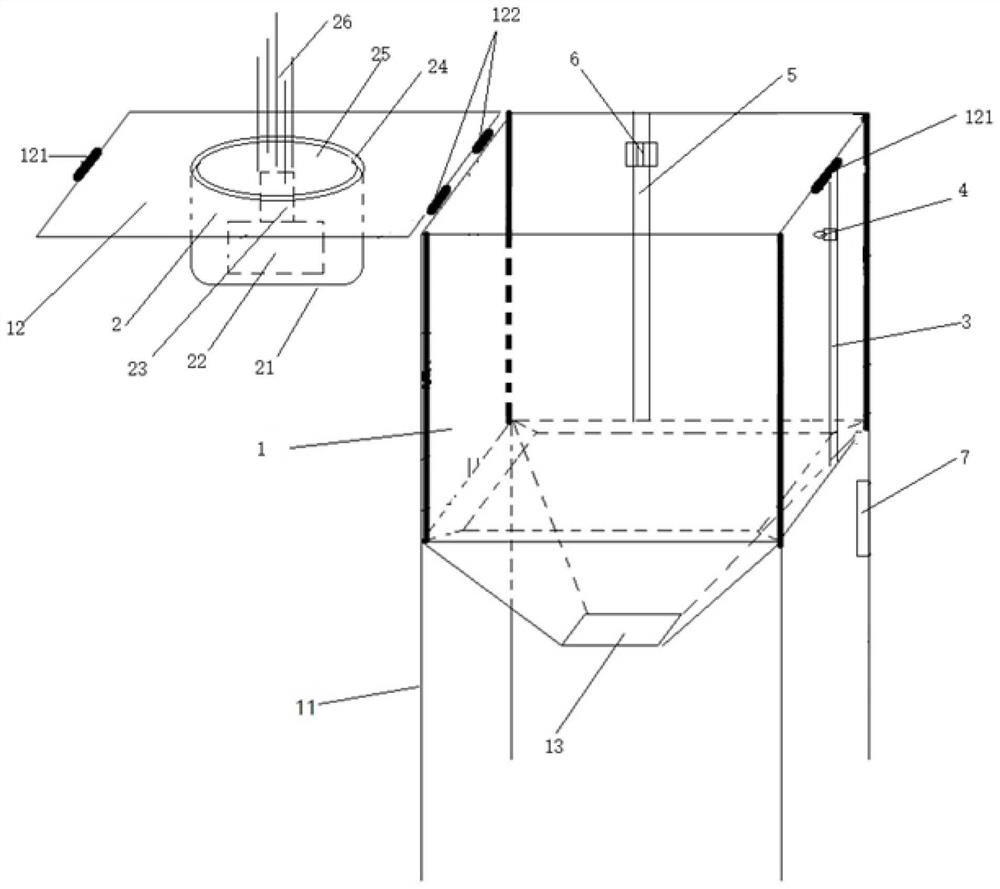

Household peeling device

The invention belongs to the technical field of kitchen supplies, discloses a household peeling device, and aims to solve the technical problem that melons and fruits are inconvenient to peel in the prior art. The device comprises a device body, and the device body comprises a rotating mechanism, a first transmission device, a camera, a second transmission device, a blade device and a processing device; the device body comprises a cavity, a cover plate is arranged above the cavity, the rotating mechanism is arranged on the cover plate, the first transmission device is arranged on one side of the device body, and the power output end of the first transmission device is in transmission connection with the camera; the second transmission device is arranged on the side adjacent to the first transmission device, and the power output end of the second transmission device is in transmission connection with the blade device.

Owner:NANJING COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com