Automatic blade mounting device for art knife

An automatic installation, utility knife technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of low installation efficiency, cumbersome steps, low safety, etc., and achieve the effect of convenient storage and access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

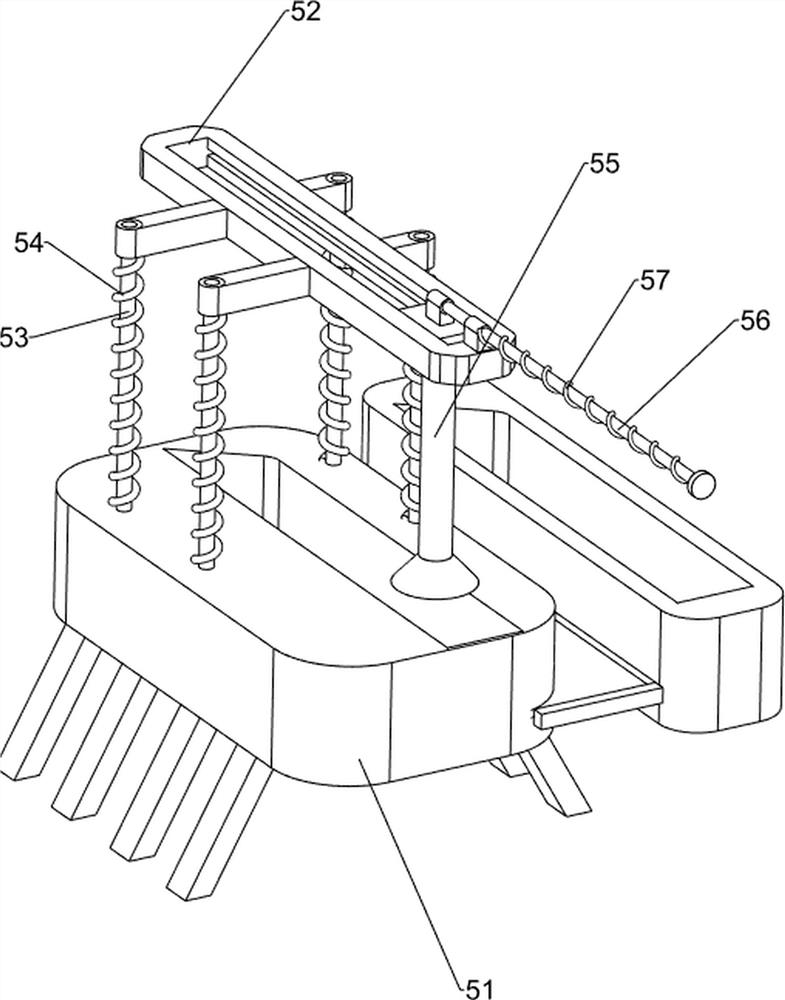

[0086] A utility knife automatically installs a blade device, such as figure 1 As shown, it includes worktable 1, air cylinder 2, unloading mechanism 3, charging mechanism 4 and suction mechanism 5. Cylinder 2 is installed on the left part of the front side of the top of the worktable 1; Feeding mechanism 3, a loading mechanism 4 is provided on the left side of the top rear of the worktable 1, and the charging mechanism 4 is connected with the unloading mechanism 3. A suction mechanism 5 is provided in the middle of the left side of the top of the worktable 1, and the middle of the right side of the top of the worktable 1 is provided. A pushing mechanism 6 is provided, and the pushing mechanism 6 is connected with the unloading mechanism 3 .

[0087] When people need to install the blade on the utility knife, this automatic blade installation device can be used. First, put the knife cover, the rear end cover and the blade into the unloading mechanism 3, the loading mechanism 4...

Embodiment 2

[0089] On the basis of Example 1, as Figure 2-10 As shown, the blanking mechanism 3 includes a first bracket 31, a base 32, a first spring rod 33, a first compression spring 34, a blanking frame 35, a fixing bolt 36, a first wedge block 37, a splint 38, a first wedge The rod 39 , the second compression spring 310 , the second wedge rod 311 and the third compression spring 312 , the first bracket 31 is symmetrically provided on the left and right sides of the top rear side of the workbench 1 , and the base 32 is provided on the left side of the top rear side of the workbench 1 . , the tops of the two first brackets 31 are provided with two first spring rods 33 , the four first spring rods 33 are all wound with a first compression spring 34 , and the bottom ends of the first compression springs 34 are connected with the first bracket 31 . A blanking frame 35 is slidably arranged between the four first spring rods 33, the top of each first spring rod 33 is provided with a fixing...

Embodiment 3

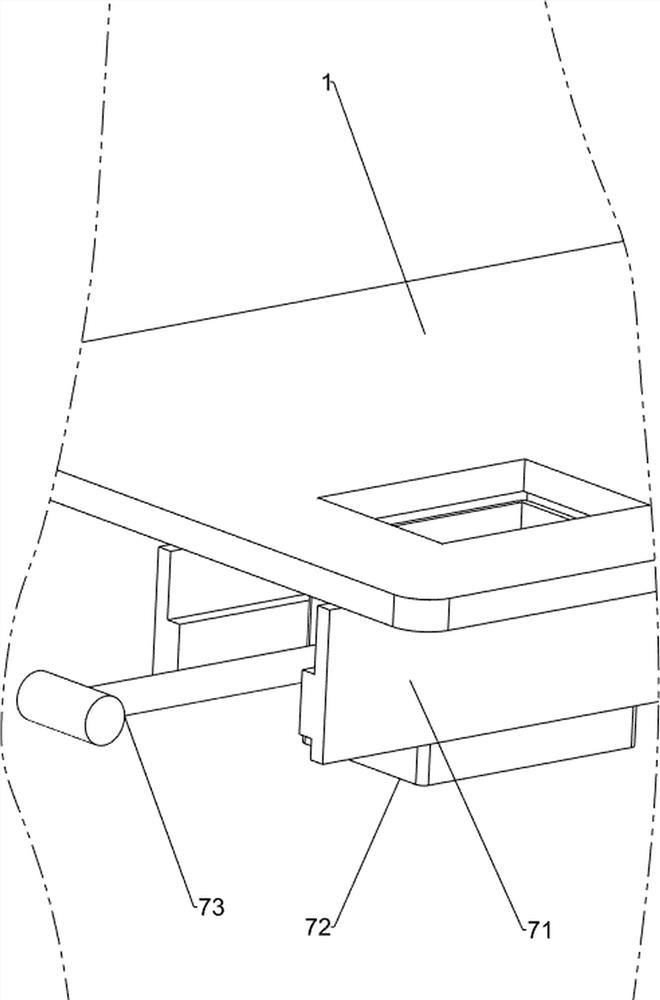

[0098] On the basis of Example 2, as Figure 11-13 As shown, it also includes a material storage mechanism 7, and the left part of the bottom rear side of the workbench 1 is provided with a material storage mechanism 7. The material storage mechanism 7 includes a fixed plate 71, a storage box 72 and a third push rod 73. The bottom of the workbench 1 is provided with a material storage mechanism 7. A fixed plate 71 is symmetrically arranged on the left part of the rear side, a storage box 72 is slidably arranged between the two fixed plates 71 , and a third push rod 73 is arranged on the rear wall of the storage box 72 .

[0099] The installed utility knives are pushed back into the storage box 72 by the sliding block 42, and people pull the third push rod 73 backward, so that the storage box 72 slides backward along the fixing plate 71, thereby taking out the collected utility knives, which is convenient for people Storage and Access.

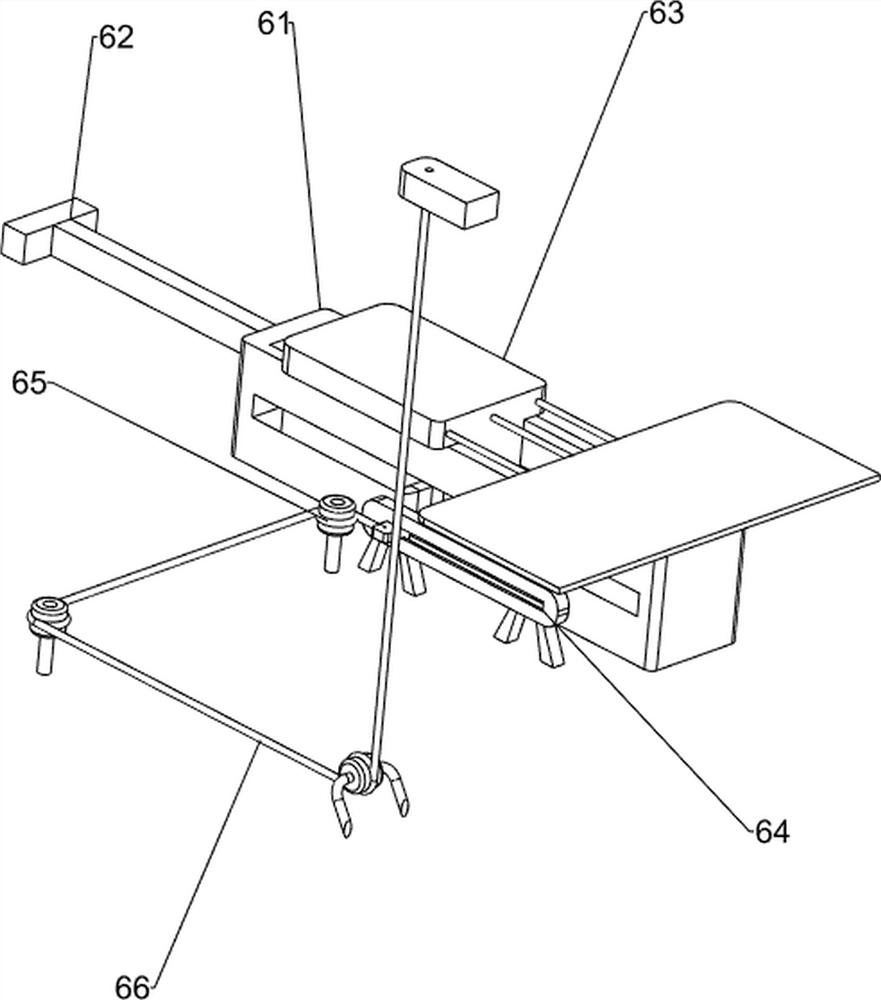

[0100] It also includes an installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com