Cable stripping device

A wire stripping device and cable technology, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., can solve the problems of inconvenient operation, thick cable skin, equipment damage, etc., and achieve the reduction of wire stripping Difficulty, weight reduction, precise control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

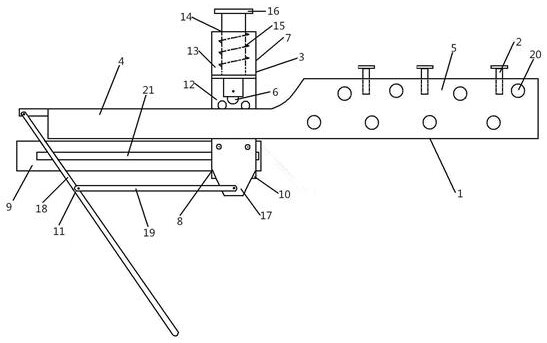

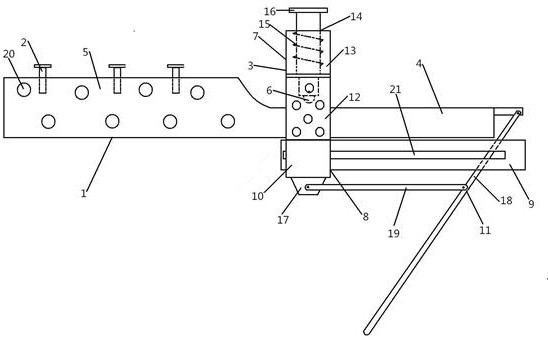

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] see Figure 1-Figure 2 , a cable stripping device, including a cable sleeve 1, a cable limiting device 2 and a blade device 3, the cable sleeve 1 is divided into a cable stripping part 4 at the front end and a cable insertion part 5 at the rear end, The cable inserting part 5 is provided with a fastening nut as the cable limiting device 2, the blade device 3 is located directly above the cable stripping part 4, and the blade device 3 includes a blade 6, a blade up and down displacement device 7 and The blade left and right displacement device 8, the blade up and down displacement device 7 includes a cylindrical housing 13 and a screw lifting device 14 screwed inside the cylindrical housing 13, and the screw lifting device 14 includes a screw screw screwed inside the cylindrical housing 13. The column 15 and the adjusting knob ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com