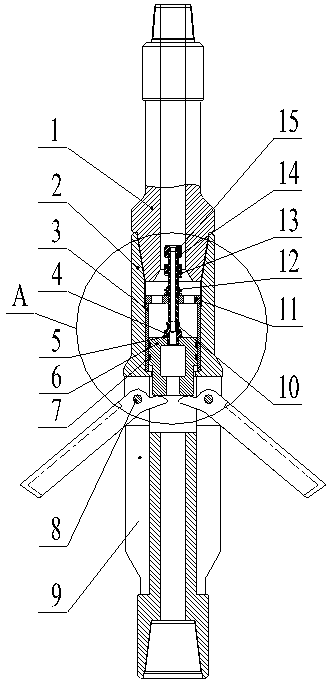

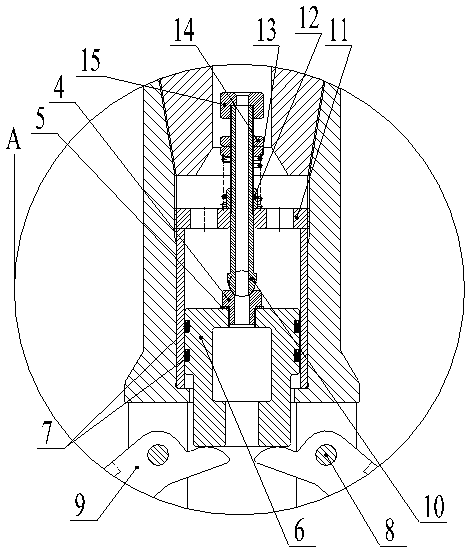

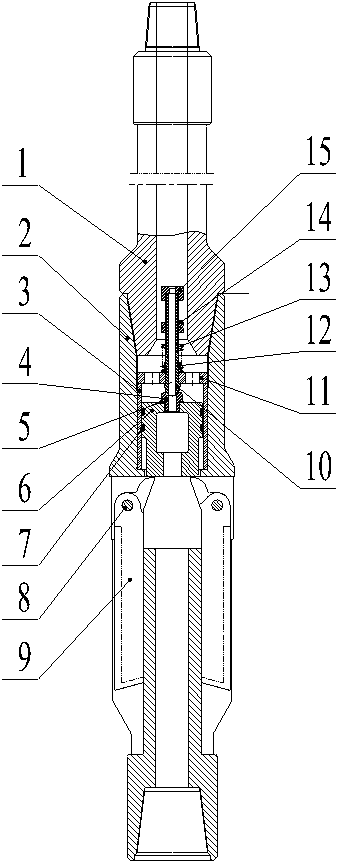

Novel deepwater large-diameter hydraulic cutting knife and efficient blade device

A large-diameter, blade technology, applied in the field of new deep-water large-diameter hydraulic cutters and high-efficiency blade devices, can solve the problems of low cutting efficiency, small number of cutting blades and chip edges, and inconvenient chip removal, so as to increase the number and discharge Effects of flutes, improved service life and cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0034] In the present invention, the new type of deep water large-diameter hydraulic cutter and the high-efficiency blade device are connected to the drilling platform, which belongs to the deep water operation tool. It is quite different from the ordinary cutting device. It is easy to understand that because it needs to be operated in deep water, the operation and control are more difficult. Big.

[0035] You must know that the cost of using a drilling platform is extremely high. For example, the 981 drilling platform is equipped with eight 44,000-kilowatt diesel generators, and the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com