A method for preparing ferroferric oxide with a porous honeycomb structure based on light-curing 3D printing technology

A ferroferric oxide, 3D printing technology, applied in 3D object support structures, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of simple structure, low precision and difficulties of ferroferric oxide , to achieve the effect of effective and fast processing means, low cost and accurate precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

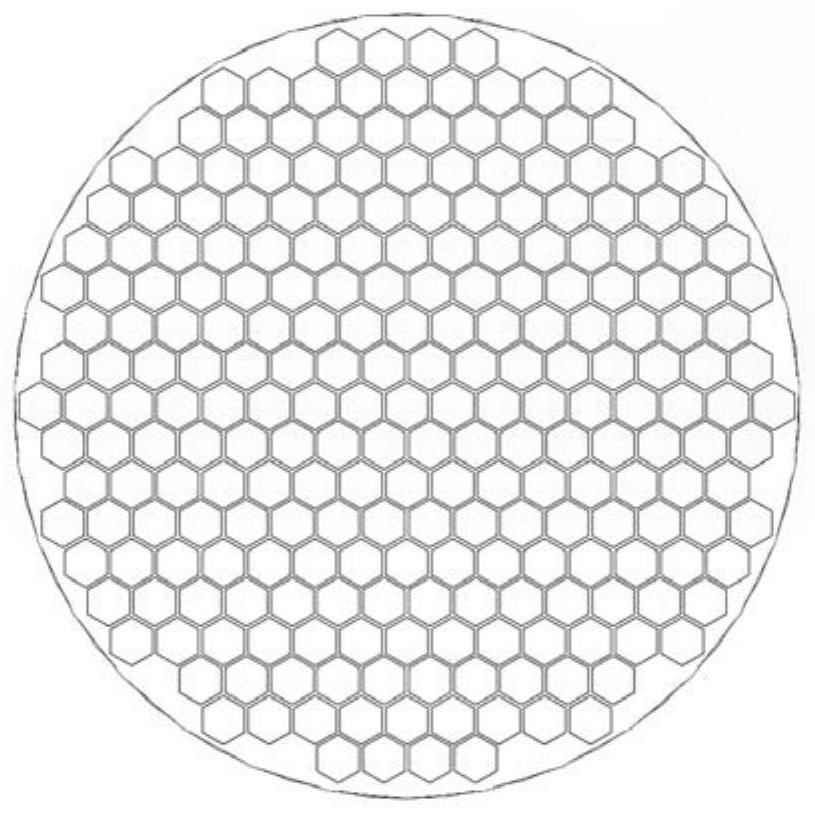

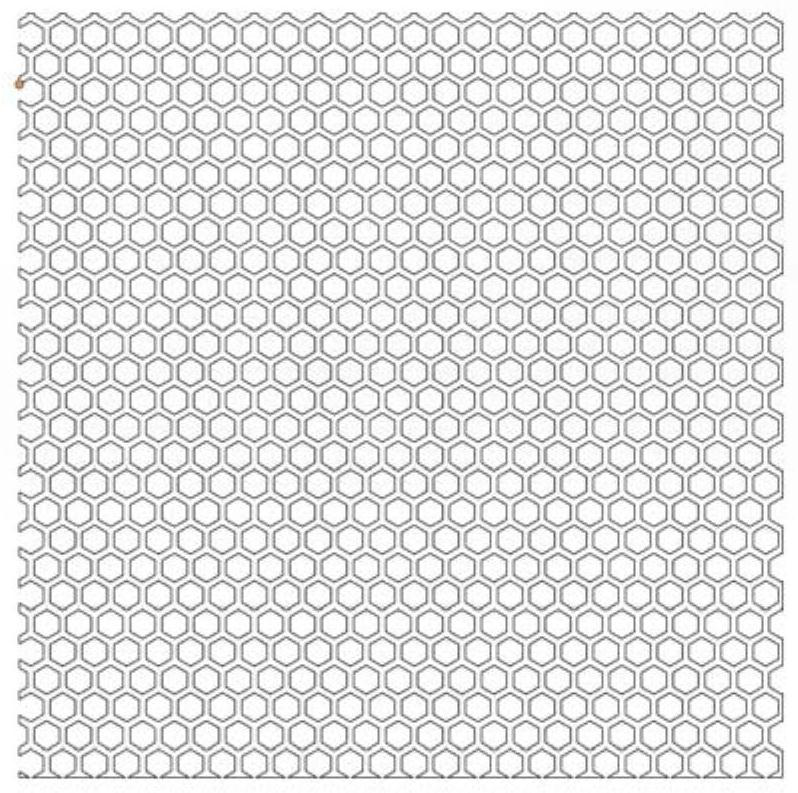

[0026] 1. Use Solidworks, Rhino and other three-dimensional modeling software to design the required porous structure, and calculate its porosity, adjust according to the mechanical simulation results of the finite element analysis software ABAQUS, and obtain the structural model with the best porosity.

[0027] 2. Configure the special slurry required for printing, use photosensitive resin as the solvent, add appropriate amount of ferric oxide powder, binder, photoinitiator, and photopolymerizer in sequence, mix thoroughly and then perform ball milling.

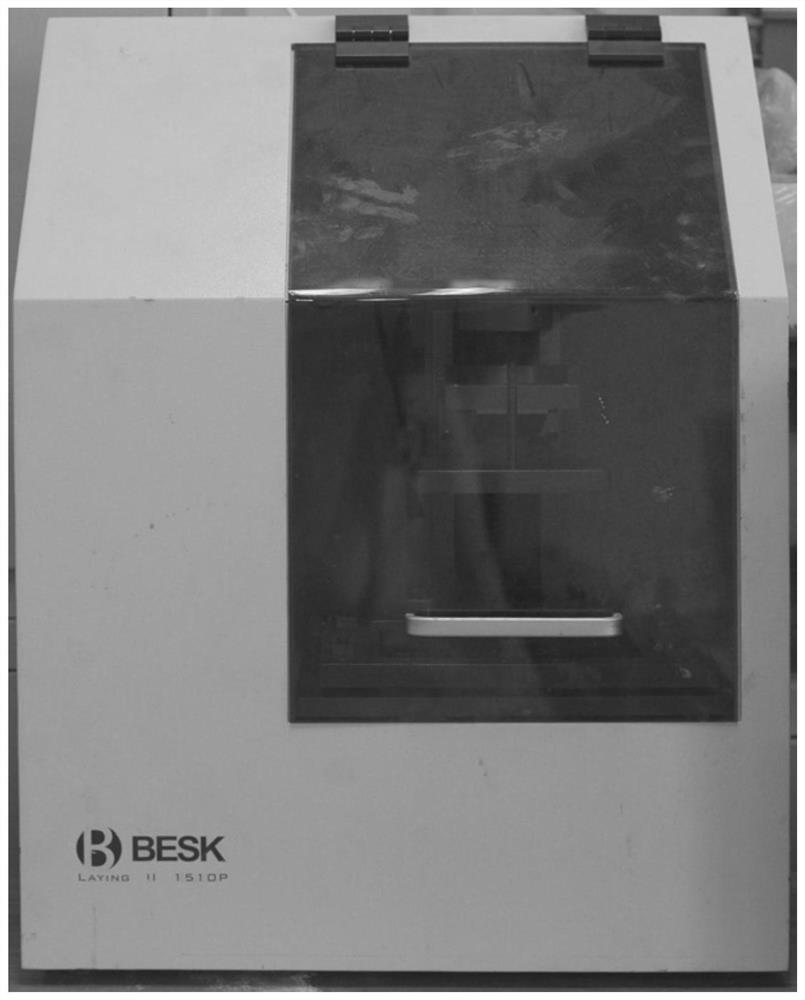

[0028] 3. Use the designed BESK printer to print. First, import the printed model data into the Q3DP software designed with the printer, adjust the parameters and slice the model, and then adjust the substrate to be parallel to the bottom resin tank and determine the best starting position , to ensure that the curing effect of the first layer is good, and start normal printing after confirming that the printing effect of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com