Polyolefin granulation method, polyolefin resin, polyolefin fiber, use of polyolefin fiber and cementitious compound

A polyolefin resin, polyolefin fiber technology, applied in the field of adding non-ionic and/or ionic surfactants, can solve the problems of complex cost, leaching loss, easy leaching, etc., and achieve excellent mechanical properties, Great adhesion, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: use following material in the preparation of described composition:

[0053] • Polypropylene: Homopolymer with a melt flow index of 18 g / 10 min.

[0054] Surfactant 1: ratio 3EO / 6PO, viscosity 45 cP (25 °C) and density 0.96 g / cm 3 (25 °C) lauryl alcohol copolymer.

[0055] Table 1 shows the mass percent of surfactant added to the polypropylene during the granulation step.

[0056] Table 1

[0057] .

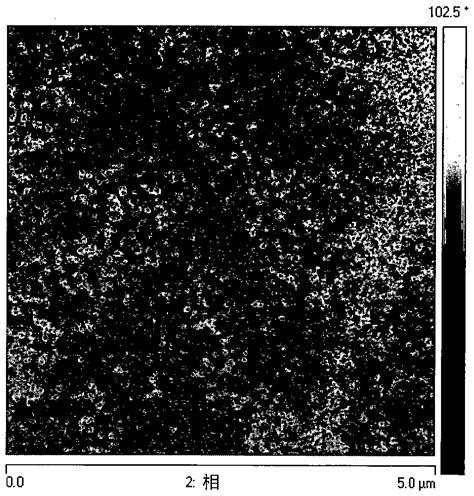

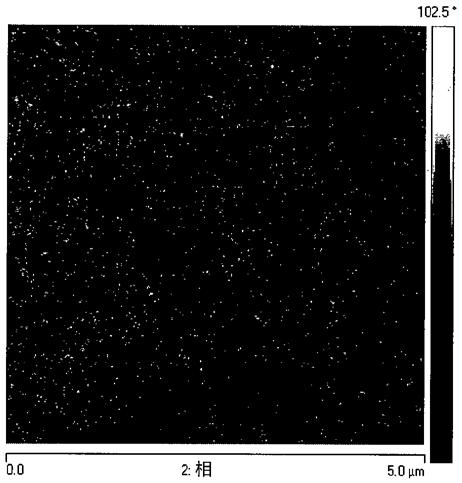

[0058] The pellets thus obtained were processed in a multifilament extruder to obtain polypropylene fibers, which were characterized by pull-out tests, atomic force microscopy (AFM) and mechanical properties such as tenacity and elongation fiber. The techniques used for characterization are listed below:

[0059] ● Pull-out test: The adhesion of fibers to cementitious substrates was evaluated by a laboratory test in which the filaments were embedded to a length of 0.5 mm-2 mm in a formulation simulating a mixture containing cement, filler, sand, Comp...

Embodiment 2

[0063] Compared to Example 1, Example 2 shows the effect of Surfactant 1 on the mechanical properties of the fibers and its performance in tests to evaluate the adhesion to cementitious composites.

[0064] Table 2

[0065] Example

Toughness (cN / dtex)

Elongation (%)

DG (J / m 2 )

t (MPa)

1

6.40 ± 0.05

26.3 ± 0.9

0-0.5

1.01

2

5.40 ± 0.16

24.6 ± 0.8

4.3

0.81

[0066] The results in Table 2 show that mechanical properties such as toughness, elongation and friction (τ) are slightly affected by the presence of nonionic surfactants, but do not impair their performance. A significant increase in binding energy (DG) was observed, similar to the properties observed for PVA fibers. These properties make the new material of industrial interest thanks to the improved performance of the fibers as reinforcements for composites.

[0067] Thus, the significant increase in the binding energy (DG) as shown in Table 2, accounts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com