Method and system of producing molded coal by coking organic castoff and weakly caking coal

A technology of organic waste and weakly caking coal, which is applied in the petroleum industry, solid fuel, fuel, etc., can solve the problems of low degree of mechanization, reduce coking costs, and affect the health of operators, so as to improve coke quality and reduce The effect of coking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

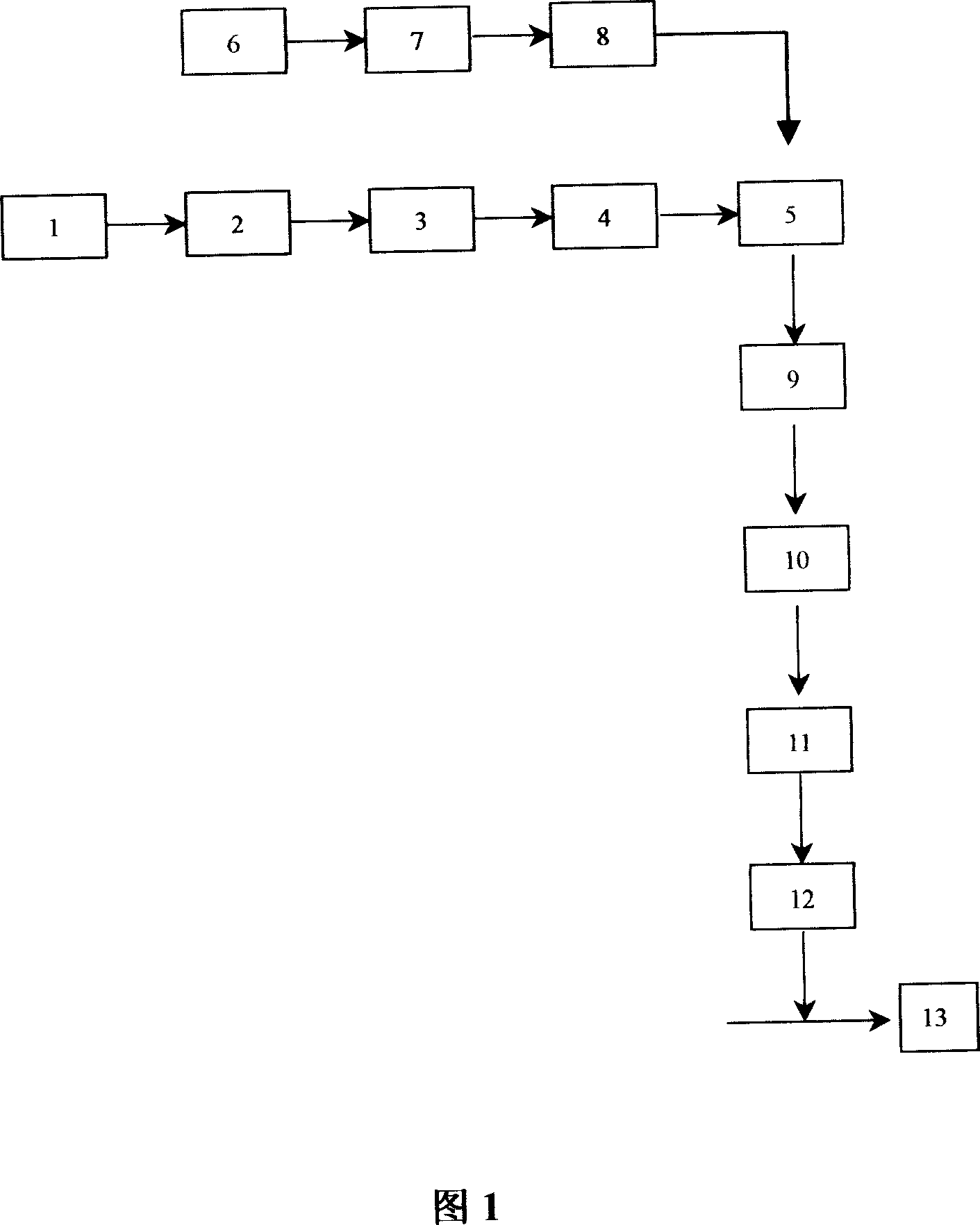

[0023] The present invention relates to a method for producing coking briquettes by using coking organic waste and weakly caking coal as raw materials. The implementation steps include: (1) first mixing and pretreating the coking organic waste collected from the coking plant; 2) pretreating the weakly caking coal used for coking; (3) quantitatively and uniformly mixing the pretreated coking organic waste and weakly caking coal; (4) molding the uniformly mixed materials to produce (5) Mix the molded coal with coking coal according to a certain ratio and enter the coke oven for coking. After pretreatment of weakly caking coal and coking organic waste, all weakly caking coal and coking organic waste are mixed to make briquettes, and the briquettes are mixed with ordinary coking coal blending and then enter the coke oven for coking. The coking organic waste mainly includes any organic waste such as tar residue, acid tar, biochemical sludge and coal tar pitch produced in a coking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com