Preparation of poly-p-phenylene benzodioxazole fibers

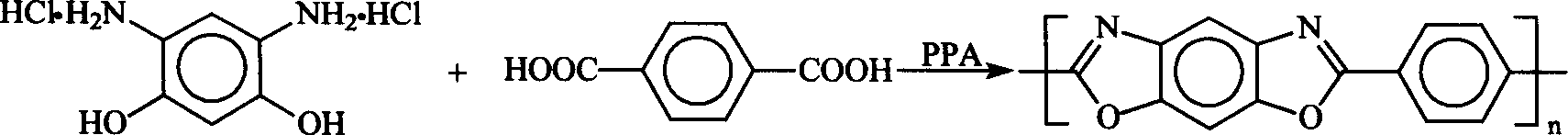

A benzobisoxazole and poly-p-phenylene technology is applied in the field of preparation of poly-p-phenylene benzobisoxazole fibers, and can solve the problems of poor fluidity, difficulty in increasing the molecular weight of PBO, loss of mixing function of a stirrer, and the like. Avoid hygroscopic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 225.8g of 4,6-diaminoresorcinol hydrochloride (DAR), 1045.6g of P 2 o 5 Concentration is 80wt% polyphosphoric acid (PPA), 157.59g terephthalic acid (TPA, 90% of total charge) and 539g of P 2 o 5 , Seal the reactor.

[0026] Raise the temperature of the reaction materials in the reactor to 50°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 65°C and keep for 1 hour to further dissolve the materials.

[0027] Fill the reactor with dry high-purity nitrogen to make the pressure in the reactor reach 1.0MPa, and at the same time raise the temperature to 120°C, keep it for 7 hours, open the pressure relief valve, and remove the pressure in the reactor. Then heat up the reaction material to 145°C, and react for 6 hours to completely discharge the remaining HCl until the neutral color is detected at the gas escape port with pH test paper, then remove the vacuum in the reactor, and then raise the temperature of the reaction ma...

Embodiment 2

[0032] Add 225.8g of 4,6-diaminoresorcinol hydrochloride (DAR), 1045.6g of P 2 o 5 Concentration is 80wt% polyphosphoric acid (PPA), 162.84g terephthalic acid (TPA, 93% of total charge) and 539g of P 2 o 5 , Seal the reactor.

[0033]Raise the temperature of the reaction materials in the reactor to 50°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 65°C and keep for 1 hour to further dissolve the materials.

[0034] Fill the reactor with dry high-purity nitrogen to make the pressure in the reactor reach 1.0MPa, and at the same time raise the temperature to 120°C, keep it for 7 hours, open the pressure relief valve, and remove the pressure in the reactor. Then heat up the reaction material to 145°C, and react for 6 hours to completely discharge the remaining HCl until the neutral color is detected at the gas escape port with pH test paper, then remove the vacuum in the reactor, and then raise the temperature of the reaction mat...

Embodiment 3

[0039] Add 225.8g of 4,6-diaminoresorcinol hydrochloride (DAR), 1045.6g of P 2 o 5 Concentration is 80wt% polyphosphoric acid (PPA), 168.1g terephthalic acid (TPA, 96% of total charge) and 539g of P 2 o 5 , Seal the reactor.

[0040] Raise the temperature of the reaction materials in the reactor to 50°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 65°C and keep for 1 hour to further dissolve the materials.

[0041] Fill the reactor with dry high-purity nitrogen to make the pressure in the reactor reach 1.0MPa, and at the same time raise the temperature to 120°C, keep it for 7 hours, open the pressure relief valve, and remove the pressure in the reactor. Then heat up the reaction material to 145°C, and react for 6 hours to completely discharge the remaining HCl until the neutral color is detected at the gas escape port with pH test paper, then remove the vacuum in the reactor, and then raise the temperature of the reaction mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com