Dye-sensitized solar cell, and seal member to be used for the dye-sensitized solar cell

A solar cell and dye-sensitized technology, which is applied in the field of dye-sensitized solar cells, can solve the problems of adverse effects of dye-sensitized solar cell structure and difficult proposals, and achieve high durability, high reliability, and high viscosity. Relay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

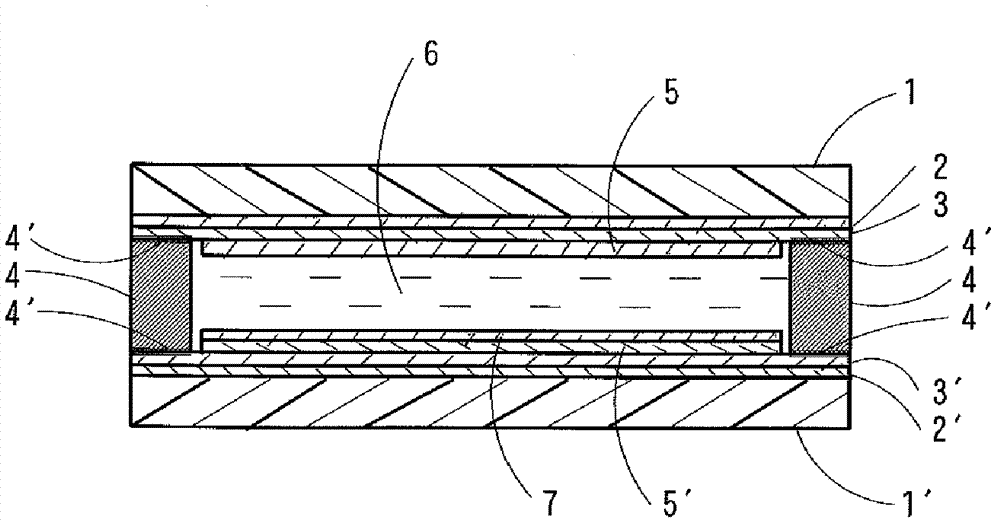

[0195] Materials shown in the following (I) to (II) were prepared and assembled as shown in (III).

[0196] (I) Fabrication of working electrode side substrate and counter electrode side substrate

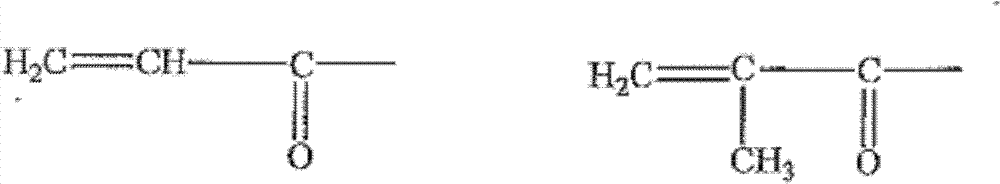

[0197] (I-a) Fabrication of a working electrode side substrate with a surface coating treatment using a specific silane coupling agent

[0198] After forming a SiOCN layer on a resin substrate [made of polyethylene naphthalate (PEN), size: 76 mm x 52 mm x thickness 125 μm] by plasma-assisted evaporation, the surface is oxidized to form SiO 2 layer, thereby forming an inorganic layer with a two-layer structure. That is, as a result, a SiOCN layer comprising a thickness of about 250 nm and a SiO layer of about 40 nm in thickness are formed. 2 The inorganic layer of the 2-layer structure of the layer. Then, on the above inorganic layer (SiO 2layer) surface to form an ITO transparent conductive electrode layer, and then form a porous titanium oxide semiconductor layer that adsorbs ...

Embodiment 2

[0206] As a silane coupling agent, on the inorganic layer (SiO 2 layer) part, instead of the methanol solution of 1 wt% 3-acryloxypropyltrimethoxysilane above, a 1 wt% methanol solution of 3-methacryloxypropyltrimethoxysilane was applied. Except for this, the dye-sensitized solar cell was assembled in the same manner as in Example 1.

Embodiment 3

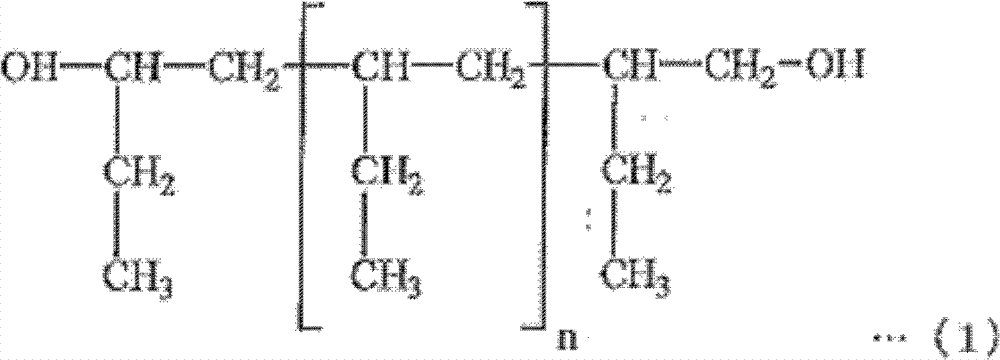

[0208] Instead of the photopolymerizable composition (A) of the above-mentioned Example 1, 7 g of the above-mentioned hydrogenated elastomer derivative a and 3 g of dimethylol dicyclopentane diacrylate (tricyclodecane dimethanol diacrylate) were used. , and a photopolymerizable composition (A) of 0.5 g of a photoradical polymerization initiator. Except for this, the dye-sensitized solar cell was assembled in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com