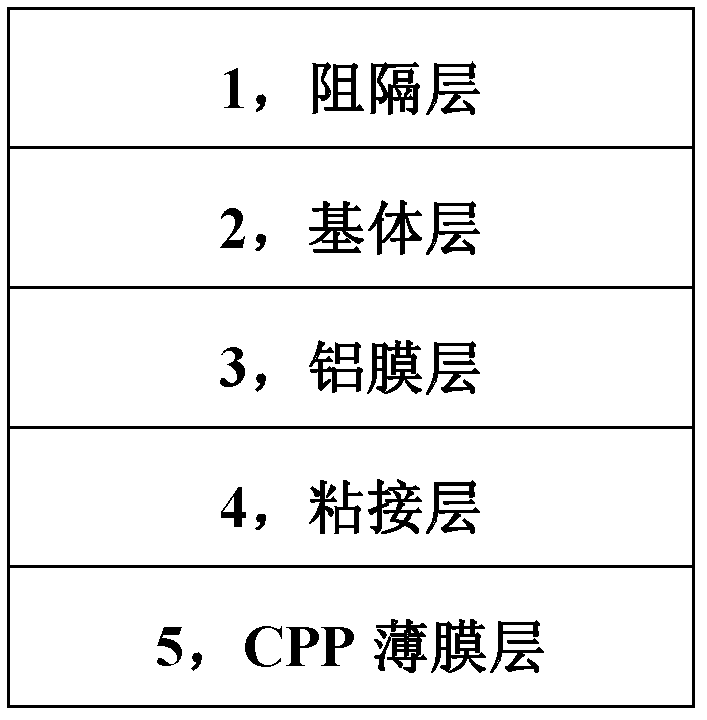

Aluminium-plastic film and preparation method for same

An aluminum-plastic film, aluminum film technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of increasing lithium battery leakage, damage and explosion, bonding layer toughness and heat-sealing bond strength Poor mechanical processing performance and other problems, to achieve the effect of good tensile strength, adjustable color, and enhanced mechanical processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with specific embodiments, and the advantages and characteristics of the present invention will become clearer along with the description. However, these embodiments are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

[0071] In the present invention, the base layer 1 is made of PI material. In addition to PI material, other materials such as polyester, polyesterimide, fluorocarbon ethylene, imide fiber paper or polybutylene terephthalate are suitable for the present invention.

[0072] The coating used in the embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com