Water-tolerant blocking polyvinyl alcohol coating for coating and preparation method thereof

A polyvinyl alcohol, water-resistant technology, applied in the direction of coating, can solve the problems of affecting the oxygen barrier performance of the coating film, the appearance of the film is not ideal, the cost is increased, etc., to achieve ideal appearance, improve sensitivity, and coating water resistance improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

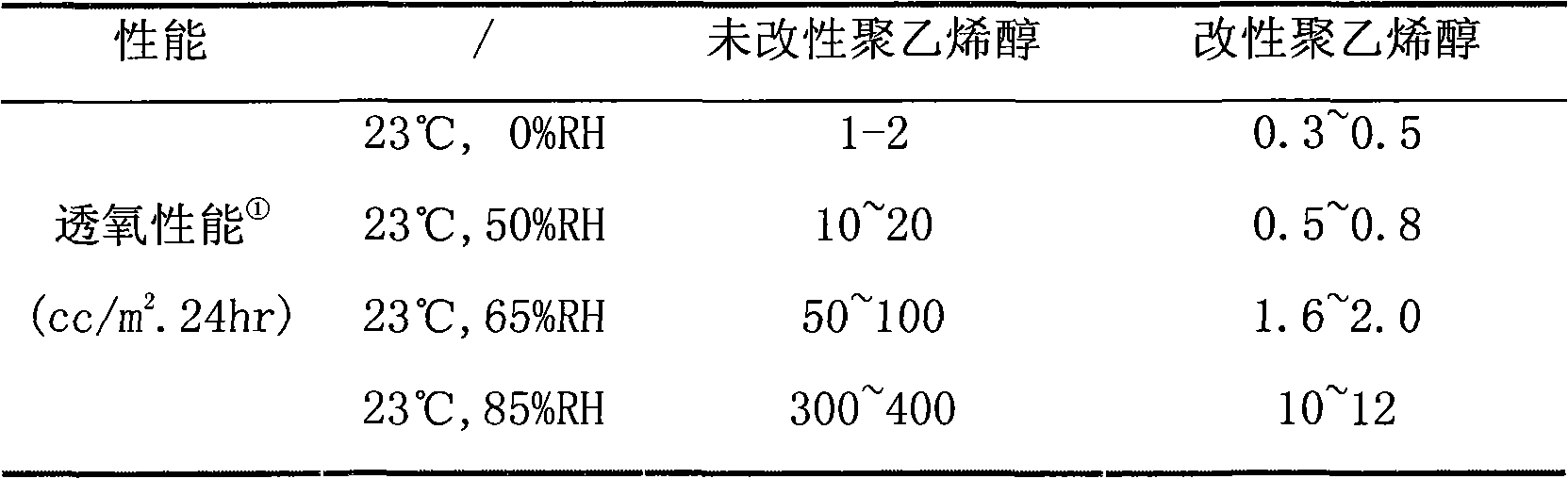

[0018] First, mix 0.3 kg of nano-montmorillonite with an ion exchange capacity of 80 mmol / 100 g and 12 kg of deionized water, stir at a high speed at 1000 rpm, and prepare a uniform and stable colloidal solution. Mix 70kg of polyvinyl alcohol with 1000kg of deionized water, start stirring at a speed of 150 rpm, raise the temperature to 95°C and keep it for 3 hours to completely dissolve, add 1kg of silicone defoamer, and then add nano-montmorillonite glue The solution was stirred for 2 hours. Cool down to 50°C, add 10kg of methyl etherified urea-formaldehyde resin and 3kg of citric acid, and stir for 2 hours. Finally, the temperature was lowered to room temperature, and the material was filtered out. The obtained modified polyethylene coating is coated on the machine, the substrate is a biaxially stretched polypropylene film of 19 μm, and the coating amount is 1.0g / m 2 After 48 hours of curing at 40°C, the oxygen permeability of the coating film was tested, and the results a...

Embodiment 2

[0020] First, mix 0.02 kg of nano-montmorillonite with an ion exchange capacity of 100 mmol / 100 g and 2 kg of deionized water, stir at a high speed at 1500 rpm, and prepare a uniform and stable colloidal solution. Mix 7.2kg of polyvinyl alcohol with 100kg of deionized water, start stirring at 200 rpm, raise the temperature to 100°C and keep it for 1 hour to completely dissolve, add 0.02kg of silicone defoamer, and then add nano-montmorillonite The clay gel was stirred for 0.5 hours. Cool down to 45°C, add 0.7kg of methyl etherified melamine resin and 0.03kg of alkyl phosphoric acid, and stir for 1 hour. Finally, the temperature was lowered to room temperature, and the material was filtered out. The obtained modified polyethylene coating is coated on the machine, the substrate is a biaxially stretched polypropylene film of 19 μm, and the coating amount is 1.0g / m 2 After 48 hours of curing at 40°C, the oxygen permeability of the coating film was tested, and the results are as ...

Embodiment 3

[0022] First, mix 0.25 kg of nano-montmorillonite with an ion exchange capacity of 85 mmol / 100 g and 10 kg of deionized water, stir at a high speed at 2000 rpm, and prepare a uniform and stable colloidal solution. Mix 30kg of polyvinyl alcohol with 500kg of deionized water, start stirring at a speed of 180 rpm, raise the temperature to 98°C and keep it for 2 hours to completely dissolve it, add 0.4kg of silicone defoamer, and then add nano-montmorillonite The gum was stirred for 1 hour. Cool down to 60° C., add 3 kg of methyl etherified urea-formaldehyde resin and 0.6 kg of maleic acid, and stir for 3 hours. Finally, the temperature was lowered to room temperature, and the material was filtered out. The obtained modified polyethylene coating is coated on the machine, the substrate is a biaxially stretched polypropylene film of 19 μm, and the coating amount is 1.0g / m 2 After 48 hours of curing at 40°C, the oxygen permeability of the coating film was tested, and the results ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com