Citicoline sodium injection and preparation method thereof

A technology of citicoline sodium and injection, which is applied in the direction of pharmaceutical formulations, medical preparations with no active ingredients, medical preparations containing active ingredients, etc., which can solve the problem of increasing dosage, unstable products, and increasing production costs and other issues to achieve the effect of improving the pass rate of light inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

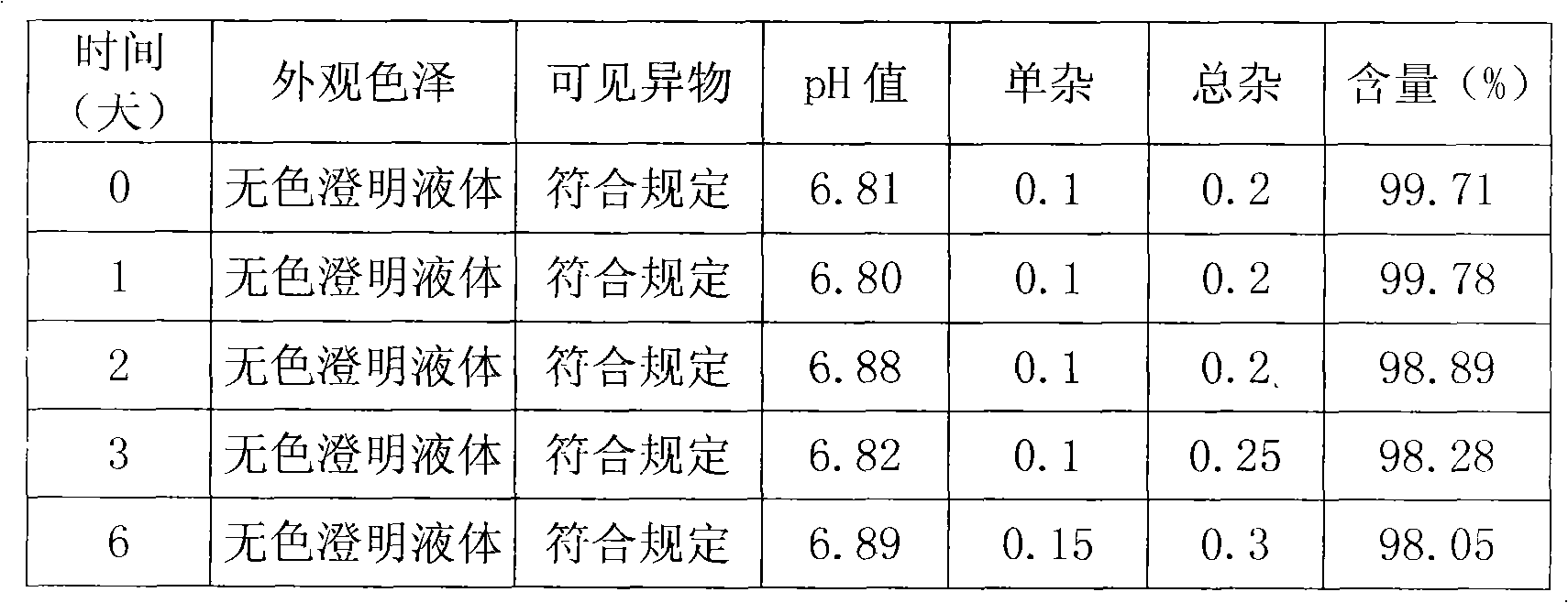

Examples

Embodiment 1

[0020] a, take by weighing citicoline sodium 2.5Kg, EDTA-2Na5g, water for injection 20000ml;

[0021] b. To be prepared in a 10,000-level environment, firstly heat the water for injection to 30°C, add 0.05% activated carbon for injection, filter after 20 minutes of adsorption, then add citicoline sodium, stir and dissolve, and use a mass-volume ratio concentration of 10 % sodium bisulfite solution to adjust the pH value to 6.5;

[0022] c. Heat the feed liquid prepared in step b to 65°C, keep it warm for 10 minutes, then add 0.05% activated carbon for injection (according to the mass ratio of feed liquid volume to activated carbon) and EDTA-2Na, stir, dissolve, and decarburize, Use a 0.2um two-stage filter to filter, and after the temperature of the feed liquid drops below 40°C, it is subpackaged into 2ml / bottle in a 100-level environment, filled and sealed (nitrogen protection), leak detection, light inspection, and packaging, and the specifications are obtained. 2ml: 0.25g ...

Embodiment 2

[0024] a, take by weighing citicoline sodium 5Kg, EDTA-2Na5g, water for injection 20000ml;

[0025] b. To be prepared in a 10,000-level environment, firstly heat the water for injection to 28°C, add 0.02% activated carbon for injection, filter after 30 minutes of adsorption, then add citicoline sodium, stir and dissolve, and use a mass-volume ratio concentration of 5 % sodium bisulfite solution to adjust the pH value to 7.0;

[0026] c. Heat the feed liquid prepared in step b to 60°C, keep it warm for 8 minutes, then add 0.02% activated carbon for injection (according to the mass ratio of feed liquid volume to activated carbon) and EDTA-2Na, stir, dissolve, and decarburize, Use a 0.2um two-stage filter to filter, and after the temperature of the feed liquid drops below 40°C, it is subpackaged into 2ml / bottle in a 100-level environment, filled and sealed (nitrogen protection), leak detection, light inspection, and packaging, and the specifications are obtained. 2ml: 0.5g of ci...

Embodiment 3

[0028] a, weigh citicoline sodium 0.1Kg, EDTA-2Na 5g, water for injection 20000ml;

[0029] b. To be prepared in a 10,000-grade environment, firstly heat the water for injection to 30°C, add 0.04% activated carbon for injection, filter after 25 minutes of adsorption, then add citicoline sodium, stir and dissolve, and use a mass-volume ratio concentration of 8 % sodium bisulfite solution to adjust the pH value to 7.5;

[0030] c. Heat the feed liquid prepared in step b to 60°C, keep it warm for 10 minutes, then add 0.05% activated carbon for injection (according to the mass ratio of feed liquid volume to activated carbon) and EDTA-2Na, stir, dissolve, and decarburize, Use a 0.2um two-stage filter to filter, and after the temperature of the feed liquid drops below 40°C, it is subpackaged into 2ml / bottle in a 100-level environment, filled and sealed (nitrogen protection), leak detection, light inspection, and packaging, and the specifications are obtained. 2ml: 100mg of citicoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com