N, P doped carbon quantum dots as well as preparation method and application thereof

A technology of carbon quantum dots and carbon sources, which is applied in the field of fluorescent carbon nanomaterials, can solve the problems of insufficient detection sensitivity of cobalt ions, cumbersome preparation methods, and insufficient sensitivity, and achieve superior fluorescence performance, simple preparation methods, and high quantum yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

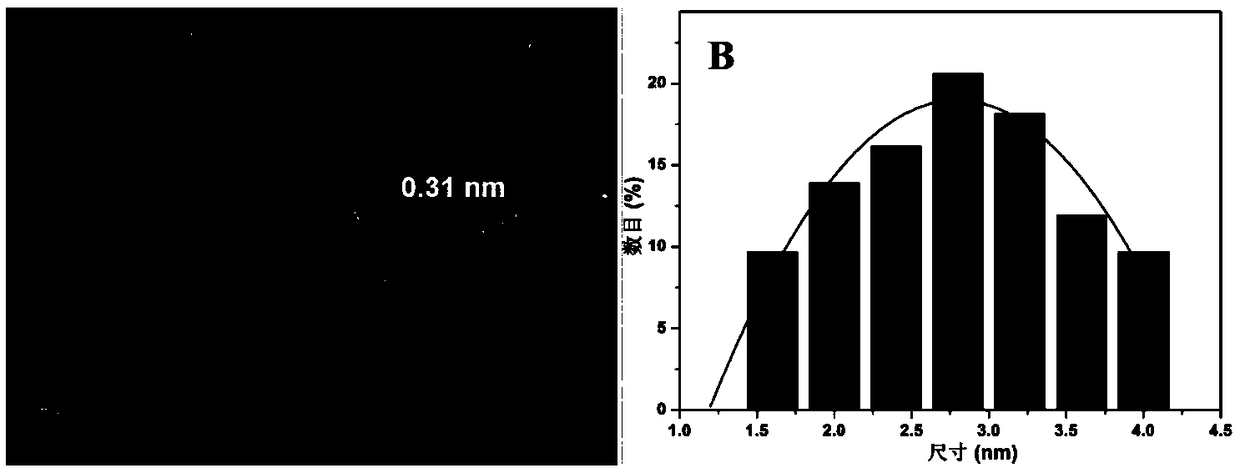

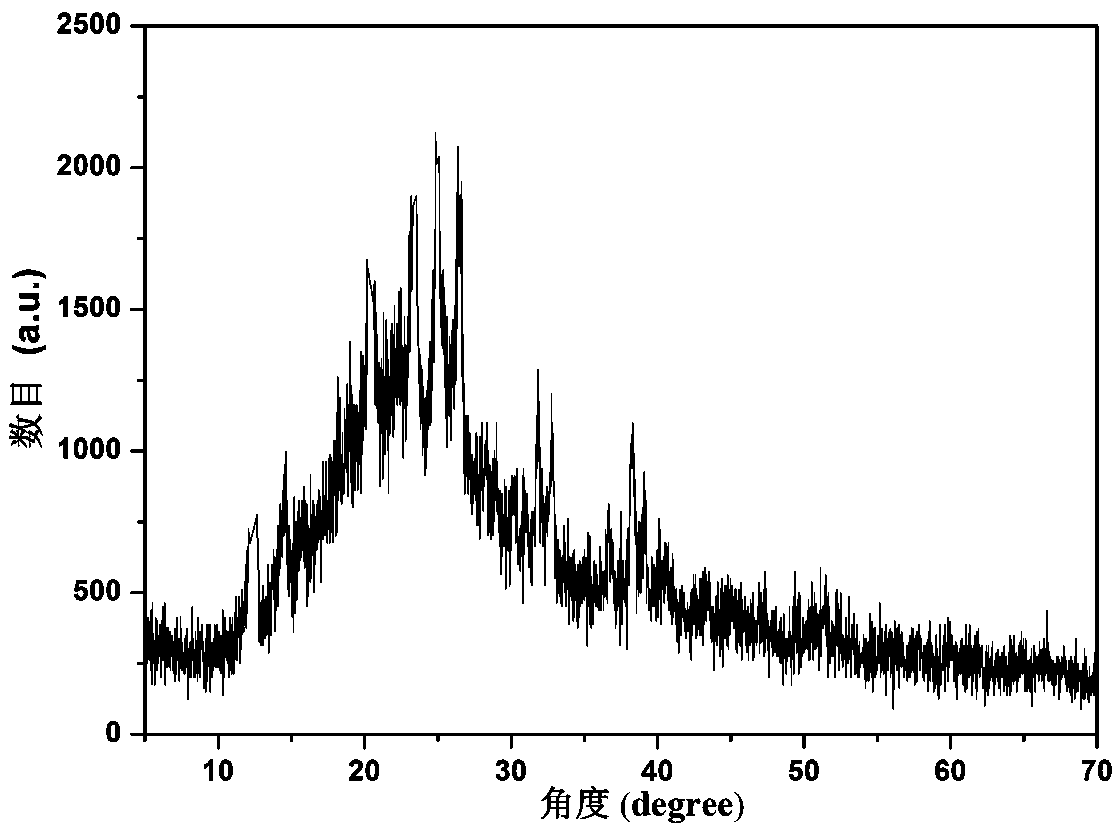

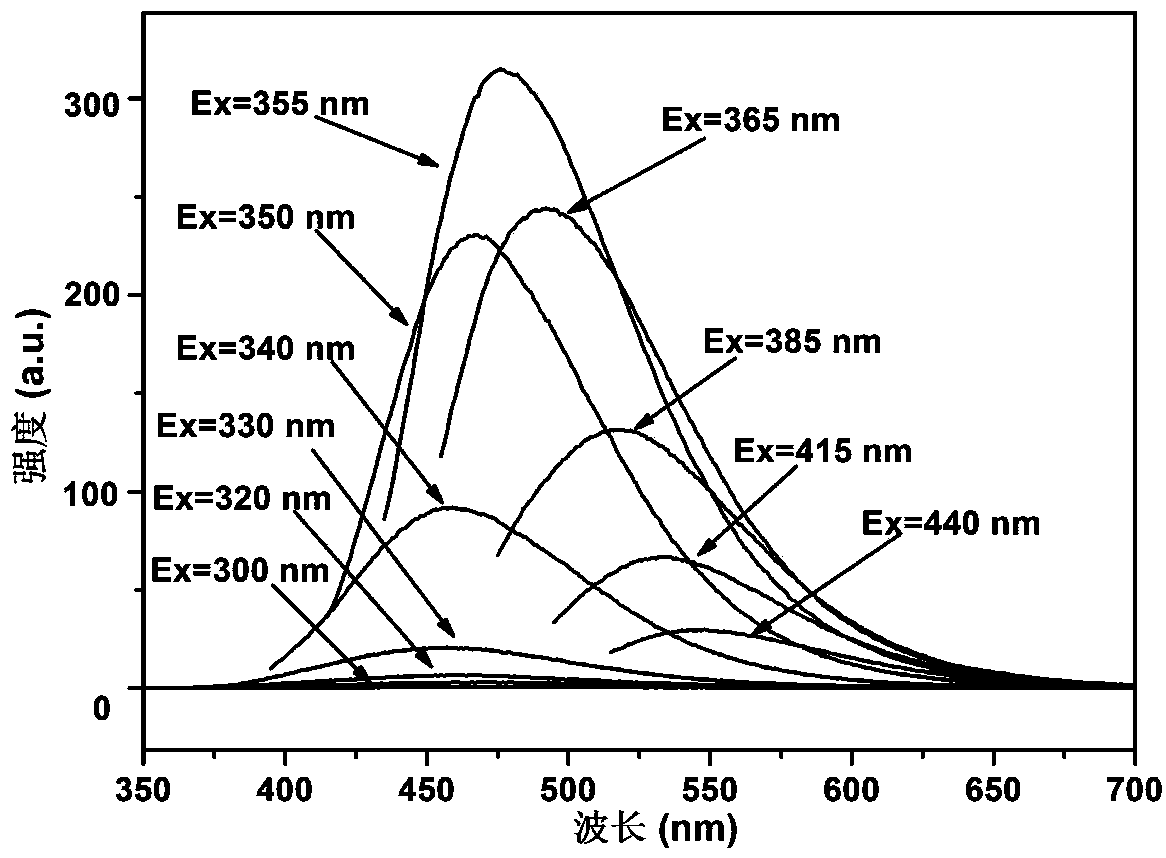

[0077] Preparation of N, P co-doped carbon quantum dots:

[0078] Step 1, weigh 0.6g of citicoline powder and place it in a 50mL clean beaker, add 0.2g of ethylenediamine and 30mL of distilled water, and completely dissolve to obtain a colorless and transparent aqueous solution.

[0079] Step 2, the colorless solution was transferred to a polytetrafluoroethylene hydrothermal reaction kettle, placed in a vacuum drying oven, and heated at a constant temperature of 180° C. for 8 hours.

[0080] Step 3, after the reaction is completed, the synthesized product is naturally cooled to room temperature, and a yellow solution will be obtained.

[0081] Step 4, the obtained yellow solution is placed in a centrifuge and centrifuged at a speed of 12000r / min for 10min, and then filtered with a 0.22μm microporous filter head to obtain a clarified carbon quantum dot solution.

[0082] Step 5, vacuum freeze-dry the obtained clear carbon quantum dot solution at a temperature of -48°C for 24 h...

Embodiment 2

[0093] Preparation of N, P co-doped carbon quantum dots:

[0094] Step 1: Weigh 0.6g of citicoline powder and place it in a 50mL clean beaker, add 0.2g of ethylenediamine and 30mL of distilled water, and completely dissolve to obtain a colorless and transparent aqueous solution.

[0095] Step 2, transfer the colorless solution to a polytetrafluoroethylene hydrothermal reaction kettle, place in a vacuum drying oven, and heat at a constant temperature of 180° C. for 4 hours.

[0096] Step 3, after the reaction is finished, the synthesized product is naturally cooled to room temperature, and the obtained yellow solution is prepared.

[0097] Step 4, the obtained yellow solution is placed in a centrifuge and centrifuged at a speed of 12000r / min for 10min, and then filtered with a 0.22μm microporous filter head to obtain a clarified carbon quantum dot solution.

[0098] Step 5, vacuum freeze-dry the obtained clear carbon quantum dot solution at a temperature of -48°C for 24 hours ...

Embodiment 3

[0100] Preparation of N, P co-doped carbon quantum dots:

[0101] Step 1, weigh 0.6g of citicoline powder and place it in a 50mL clean beaker, add 0.2g of ethylenediamine and 30mL of distilled water, and completely dissolve to obtain a colorless and transparent aqueous solution.

[0102] Step 2: Transfer the colorless solution to a polytetrafluoroethylene hydrothermal reaction kettle, place it in a vacuum drying oven, and heat it at a constant temperature at 180° C. for 6 hours.

[0103] Step 3, after the reaction is finished, the synthesized product is naturally cooled to room temperature, and the obtained yellow solution is prepared.

[0104] Step 4, the obtained yellow solution is placed in a centrifuge and centrifuged at a speed of 12000r / min for 10min, and then filtered with a 0.22μm microporous filter head to obtain a clarified carbon quantum dot solution.

[0105] Step 5, vacuum freeze-dry the obtained clear carbon quantum dot solution at a temperature of -48°C for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com