Method for purifying citicoline from biotransformation or multienzyme reaction liquid

A technology of citicoline and enzyme reaction solution, which is applied in the field of separation and purification of citicoline, can solve the problem of cytidine acid being unable to be recovered, and achieves the effects of excellent product quality, good separation effect and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

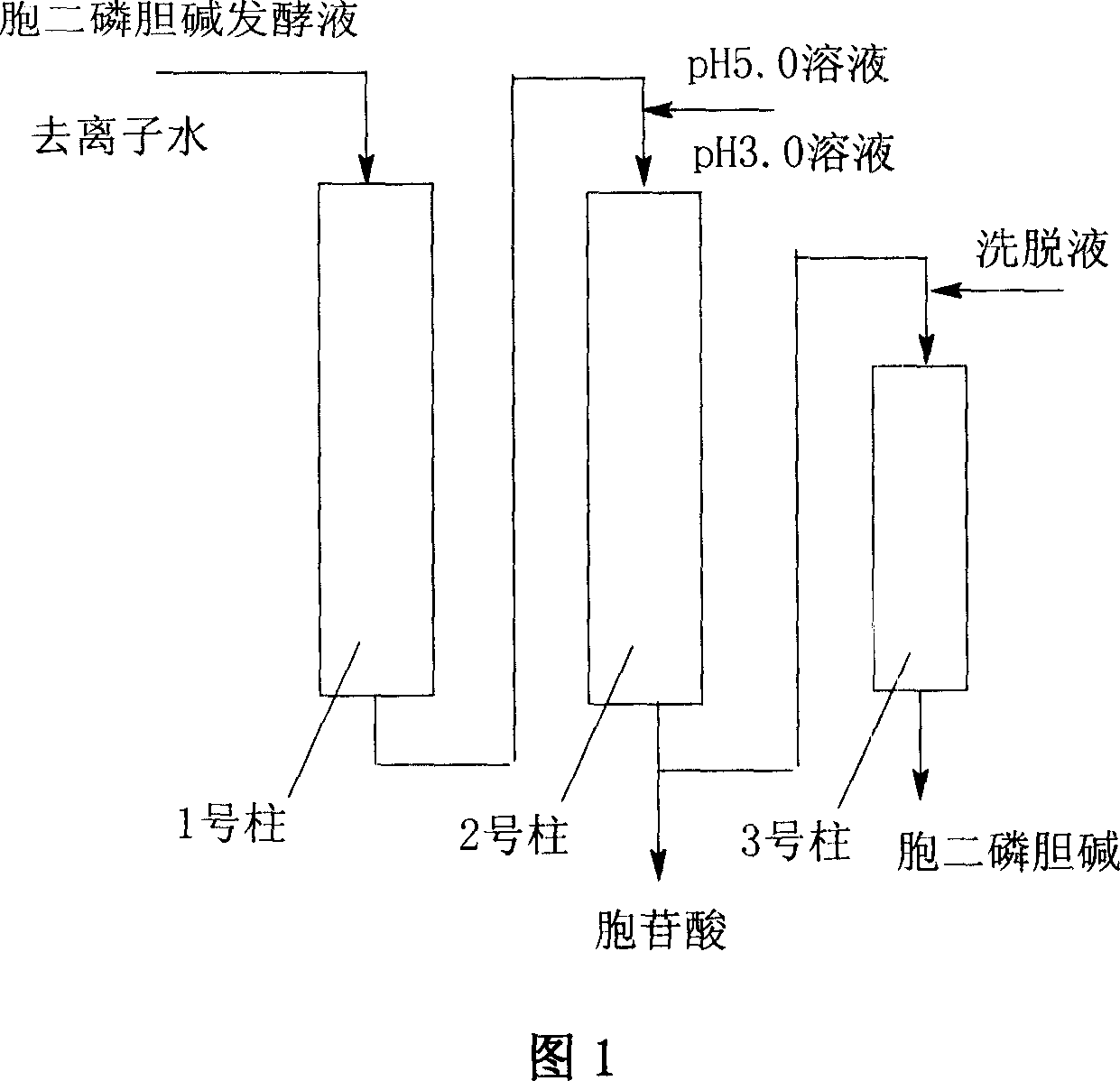

[0037] 4000mL LCDP-C reaction liquid, containing CDP-C 34.5g, CMP 5.0g, phosphate 150g, phosphorylcholine 40g, magnesium sulfate 9.7g, protein 107mg, pass 1-3 in order #Column, the flow rate is 0.3m / h. The size of column 1 is 40×1000mm, containing 1000mL of treated HD-1(H+) resin; the size of column 2 is 60×1000mm, containing 2000mL of treated D315(OH-) resin; the size of column 3 is 30×1000mm, Pack 500mL of treated HZ201 resin.

[0038] After loading the column, rinse with 1000mL deionized water. Disconnect column 1 and column 2. Then column 2 was rinsed with 1500 mL of dilute hydrochloric acid solution at pH 5.0. Disconnect column 2 and column 3. Column 3 was then eluted with a pH 2 dilute hydrochloric acid solution (containing 4% sodium chloride). Collect about 800 mL of the eluate containing CDP-C, concentrate to 100 mL, and adjust the pH to 7.5 with sodium hydroxide. Add 400mL of absolute ethanol, stir evenly, place at 4°C for 16 hours, filter and crystallize, and d...

Embodiment 2

[0041] 4000mL of the CDP-reaction solution in Example 1 was passed through 1-3 successively # Column, the flow rate is 0.3m / h.

[0042] The size of column 1 is 40×1000mm, containing 1000mL of treated HD-1(H+) resin; the size of column 2 is 60×1000mm, containing 2200mL of treated D301(OH-) resin; Pack 450 mL of treated Amberlite IRA-900 (OH-) resin.

[0043] Others are operated according to Example 1.

[0044] As a result, 28.5 g of CDP-C sodium salt was obtained with a purity of 98.9% and a yield of 82.6 g. 4.0 g of cytidylic acid was recovered with a yield of 80%.

Embodiment 3

[0046] The CDP-C (A) obtained in Example 1 and the CDP-C (B) prepared by the traditional process were prepared into a 0.125 g / mL solution with sterile water, vacuum-sealed, and heated at 110° C. for 30 minutes. After cooling, the absorbance was measured at 430nm, and the results are shown in Table 1.

[0047] Table 1

[0048] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com