Phosphorus doping silicon wafer, manufacturing method of phosphorus doping silicon wafer, solar cell and manufacturing method of solar cell

A technology for solar cells and solar cells, applied in the field of solar cells, can solve the problems of reducing the lifetime of carriers, being disadvantageous, reducing the recombination rate of carriers, etc., achieving a smooth distribution curve of impurity phosphorus concentration gradient, improving conversion efficiency, The effect of good electrical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

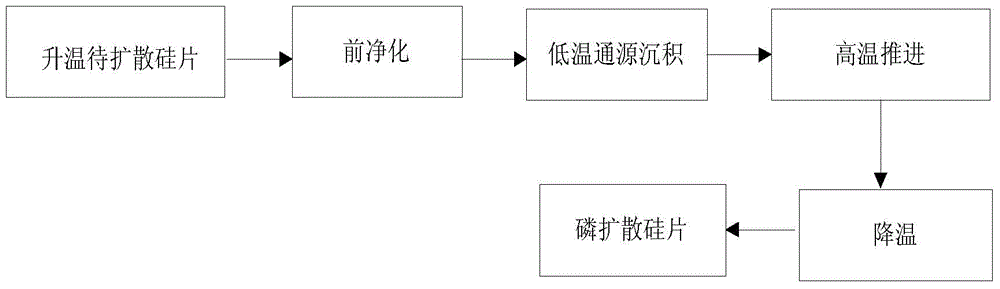

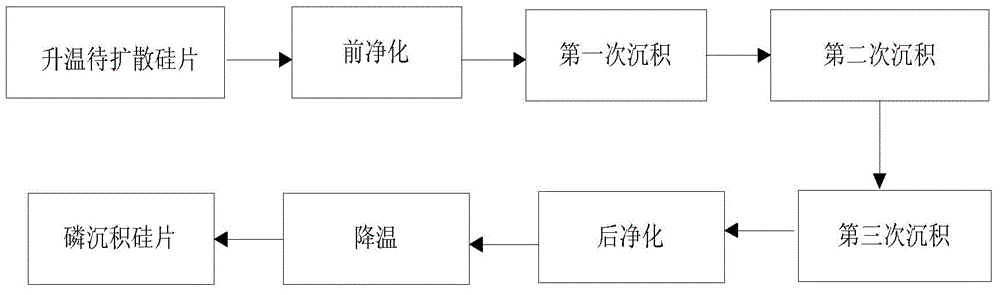

Method used

Image

Examples

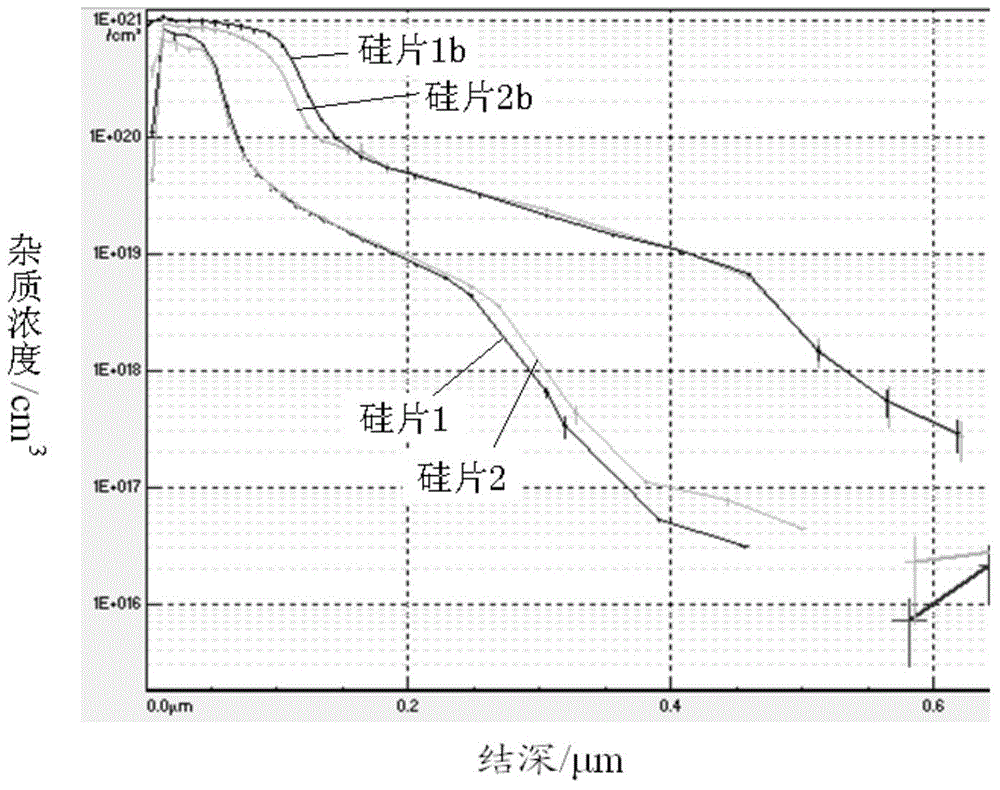

Embodiment 1

[0035] Place the P-type silicon chip in a quartz tube, raise the temperature to 860°C at 10°C / min, and pass nitrogen gas for 5 minutes while raising the temperature, with a flow rate of 8slm. After that, POCl is introduced in three steps 3 with O 2 Deposition and diffusion, where the conditions for the first step of deposition and diffusion are: POCl 3 with O 2 The total flow rate is 1600sccm, according to the volume ratio of POCl 3 :O 2 =8:1, the time of deposition and diffusion is 8 minutes; the second step of deposition and diffusion: POCl 3 with O 2 The total flow rate is 1200sccm, according to the volume ratio of POCl 3 :O 2 =5:1, the time of deposition and diffusion is 8 minutes; the third step of deposition and diffusion: POCl 3 with O 2 The total flow rate is 600sccm, by volume POCl 3 :O 2 =3:1, the deposition and diffusion time is 8 minutes. Afterwards, the temperature was lowered to room temperature at 10° C. / min, and the silicon wafer was taken out, whic...

Embodiment 2

[0037] Place the P-type silicon chip in a quartz tube, raise the temperature to 870°C at 10°C / min, and pass nitrogen gas for 2 minutes while raising the temperature, with a flow rate of 15slm. After that, POCl is introduced in three steps 3 with O 2 Deposition and diffusion, where the conditions for the first step of deposition and diffusion are: POCl 3 with O 2 The total flow rate is 1800sccm, according to the volume ratio of POCl 3 :O 2 =9:1, the time of deposition and diffusion is 5 minutes; the second step of deposition and diffusion: POCl 3 with O 2 The total flow rate is 1300sccm, by volume ratio POCl 3 :O 2 =5.5:1, the time of deposition and diffusion is 10 minutes; the third step of deposition and diffusion: POCl 3 with O 2 The total flow rate is 800sccm, according to the volume ratio of POCl 3 :O 2 =3.5:1, the deposition and diffusion time is 5 minutes. Afterwards, the temperature was lowered to room temperature at 10° C. / min, and the silicon wafer was tak...

Embodiment 3

[0039] Place the P-type silicon wafer in a quartz tube, raise the temperature to 840°C at 10°C / min, and pass nitrogen gas for 5 minutes while raising the temperature, with a flow rate of 8slm. After that, POCl is introduced in three steps 3 with O 2 Deposition and diffusion, where the conditions for the first step of deposition and diffusion are: POCl 3 with O 2 The total flow rate is 1400sccm, by volume ratio POCl 3 :O 2 =7:1, the time of deposition and diffusion is 10 minutes; the second step of deposition and diffusion: POCl 3 with O 2 The total flow rate is 1100sccm, according to the volume ratio of POCl 3 :O 2 =4.5:1, the time of deposition and diffusion is 5 minutes; the third step of deposition and diffusion: POCl 3 with O 2 The total flow rate is 600sccm, by volume POCl 3 :O 2 =2.5:1, the time of deposition and diffusion is 10 minutes. Afterwards, the temperature was lowered to room temperature at 10° C. / min, and the silicon wafer was taken out, which was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com