Chemical polymerization solution, conductive polymer solid slice aluminum electrolytic capacitor and preparation method thereof

A technology of aluminum electrolytic capacitors and conductive polymers, applied in solid electrolytic capacitors, electrolytic capacitor manufacturing, electrolytic capacitors, etc., can solve problems such as unobtainable and unapplied high-capacity products, solid capacitor capacity, loss ESR differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

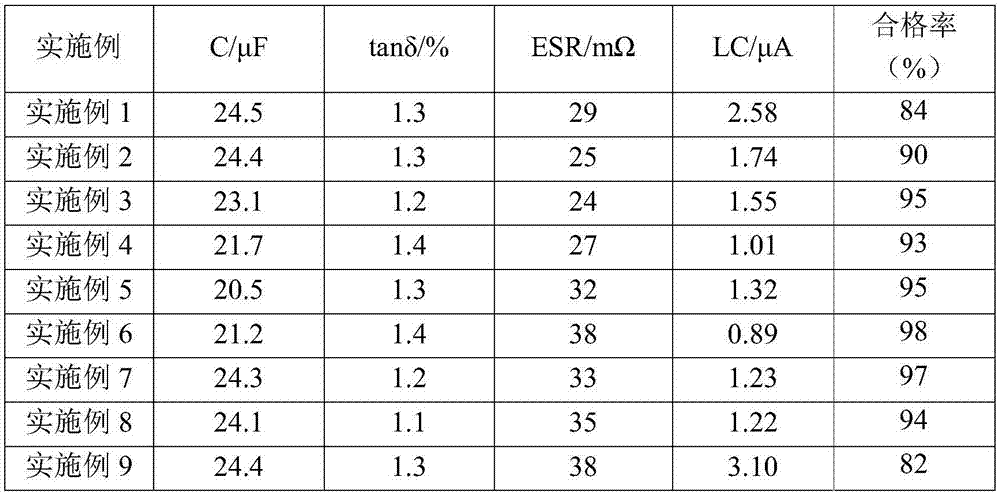

Examples

preparation example Construction

[0040] An embodiment of the present invention provides a method for preparing a conductive polymer solid chip aluminum electrolytic capacitor, which includes the following steps:

[0041] S1. Put the aluminum foil to be polymerized into the pretreatment liquid for the first stage performance modification treatment. The pretreatment liquid is mainly composed of monomers, solvents and coupling agents. Take it out after 50-120s and dry it. Oven at 50-65°C for 8-12 minutes, then put in an oven at 110-125°C for 8-12 minutes, and cool at room temperature to obtain pretreated aluminum foil. In this embodiment, the aluminum foil is used as the anode of the capacitor, and the pretreatment solution treats the surface of the aluminum foil, which can increase the capacity extraction rate of the aluminum foil. In this embodiment, the 14VF aluminum foil containing alumina is generally cut into an aluminum foil with an effective area of 3.6mm×4.5mm and the oxide film is chemically repaired...

Embodiment 1

[0053] This embodiment provides a conductive polymer solid chip aluminum electrolytic capacitor, which is prepared according to the following preparation method:

[0054] (1) Preparation of pretreatment solution: respectively add 2 g of N-methylpyrrole (monomer) and 2 g of silane coupling agent (coupling agent) to 100 g of ethanol (solvent), and stir magnetically for 3 min.

[0055] Preparation of chemical polymerization solution: Take 8g of silane coupling agent (coupling agent) and add it to 100g of ethanol (solvent), stir magnetically for 3min, add 8g of iron p-toluenesulfonate (oxide), stir magnetically for 1min, then add 2g of N-methyl base pyrrole (monomer), magnetically stirred for 1 min.

[0056] Preparation of mixed solution: 60g of ethanol (solvent) and 10g of silane coupling agent (coupling agent) were stirred and mixed evenly.

[0057] (2) Cut the 14VF aluminum foil containing alumina into an aluminum foil with an effective area of 3.6mm×4.5mm and form it into a...

Embodiment 2

[0065] This embodiment provides a conductive polymer solid chip aluminum electrolytic capacitor, which is prepared according to the following preparation method:

[0066] (1) Preparation of pretreatment solution: respectively add 2 g of N-methylpyrrole (monomer) and 2 g of silane coupling agent (coupling agent) to 100 g of ethanol (solvent), and stir magnetically for 3 min.

[0067] Preparation of the first chemical polymerization solution: Take 8g of silane coupling agent (coupling agent) and add it to 100g of ethanol (solvent), stir magnetically for 3min, add 8g iron p-toluenesulfonate (oxide), stir magnetically for 1min, then add 2g N - Methylpyrrole (monomer), magnetically stirred for 1 min.

[0068] Preparation of the second chemical polymerization solution: Take 6g of silane coupling agent (coupling agent) and add it to 100g of ethanol (solvent), stir magnetically for 3min, add 12g iron p-toluenesulfonate (oxide), stir magnetically for 1min, then add 4g N - Methylpyrrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com