Activated Carbon Materials For High Energy Density Ultracapacitors

a carbon-based electrode and high-energy-density technology, which is applied in the direction of organic compounds/hydrides/coordination complex catalysts, cell components, physical/chemical process catalysts, etc., can solve the problems of high limited cell voltage by electrolyte decomposition, and achieve high energy density devices , the cost of such carbon-based electrodes can be high, and the cost of synthetic resins high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0064]Wheat flour was first carbonized in flowing nitrogen at 800° C. for 2 hours. The resulting carbonized precursor was then mixed with a KOH solution (46 wt. % in water) in 1:5 (wt. / wt.) ratio of carbon:KOH. The mixture was heated in nitrogen to 800° C. for 2 hours and cooled to room temperature. The cooled mixture was washed with water and then with dilute HCl to remove potassium. Complete elimination of potassium was confirmed by monitoring the pH of the effluent. The carbon powder product was dried and ground to a fine powder (˜10 micrometers).

[0065]Eighty grams of the carbon powder was mixed with 10 grams of carbon black and 10 grams of PTFE to obtain a well-mixed mass. This mixture was then rolled on a roll mill to obtain a well-knit film having a thickness of about 100 micrometers. Carbon-based electrodes were produced by stamping the thin film.

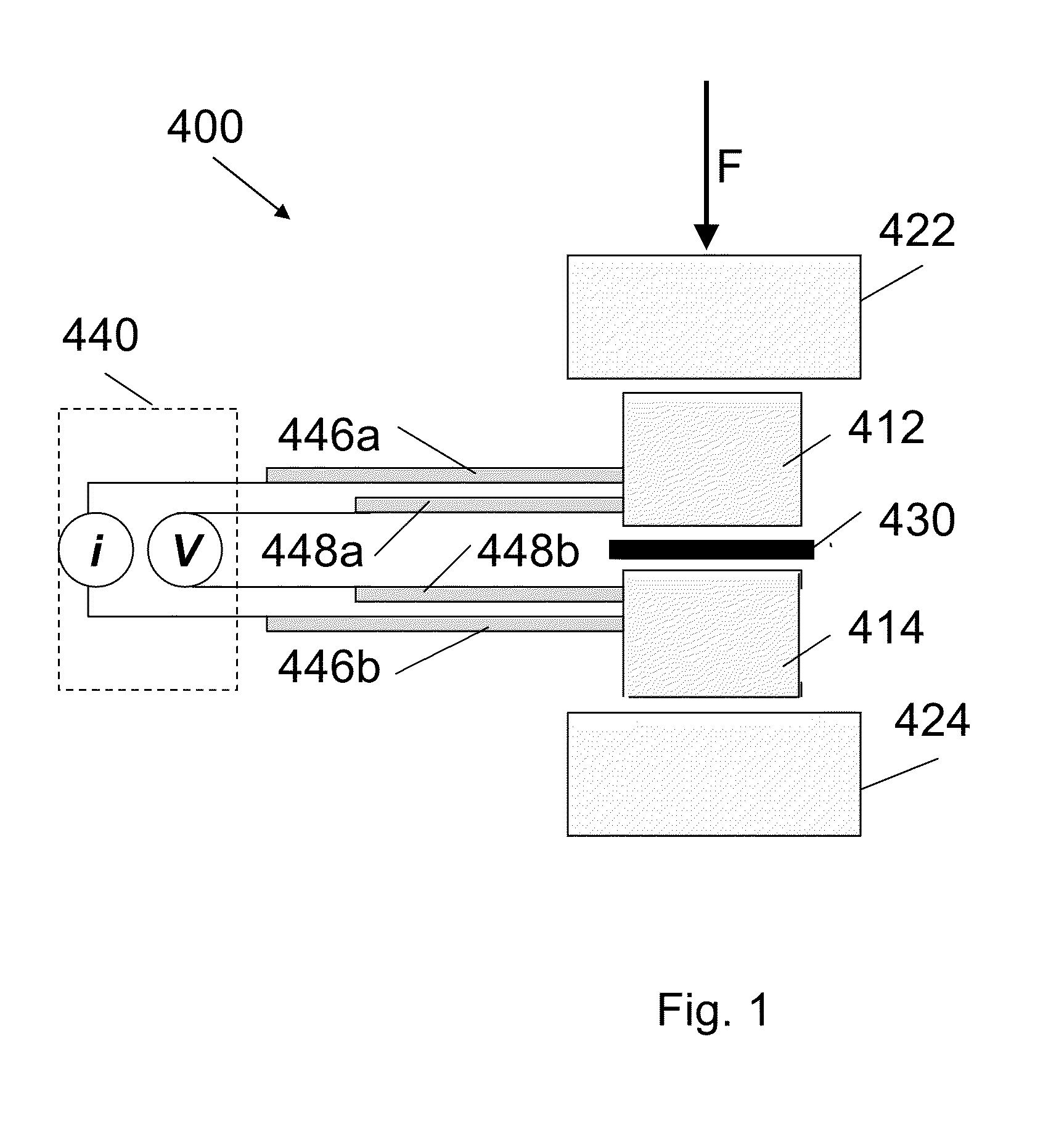

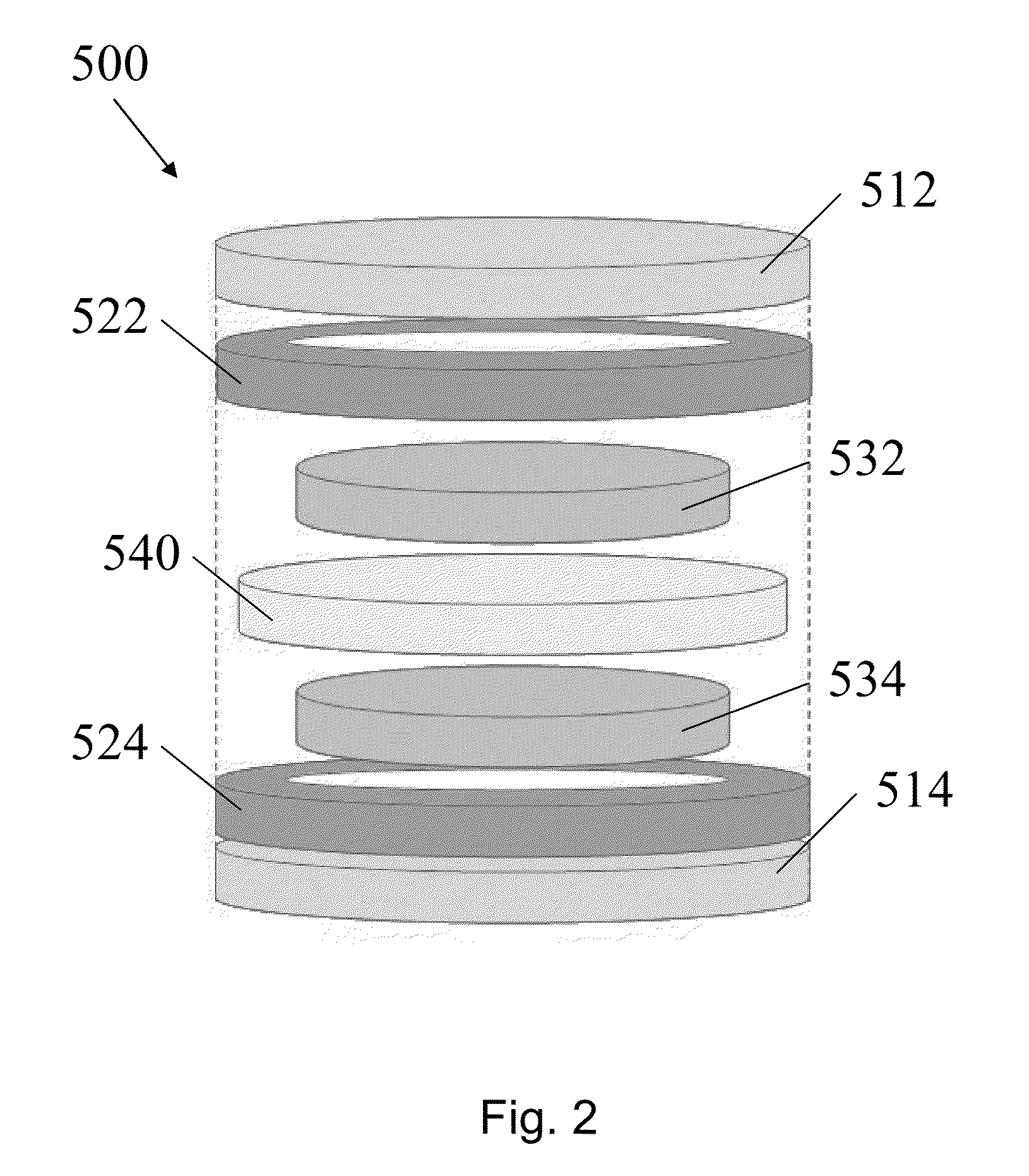

[0066]The carbon-based electrodes were soaked in 1.5 M tetraethylammonium-tetrafluoroborate (TEA-TFB) in acetonitrile. A porous sep...

example 2

[0067]The experiment of Example 1 was repeated, except corn flour was substituted for wheat flour. The volumetric capacitance of the activated carbon electrode was 97 F / cm3.

example 6

[0075]Wheat flour was mixed with a KOH solution (46 wt. % in water) to obtain a 1:3 ratio (wt. / wt.) of flour:KOH. The mixture was allowed to age for 1 hour to allow incorporation of the KOH into the wheat flour structure. The mixture was then placed into a controlled atmosphere furnace, heated under flowing nitrogen to 800° C. for 4 hours, and cooled in nitrogen to room temperature.

[0076]After cooling, the mixture was washed initially with water and then with dilute HCl to remove potassium. Complete elimination of potassium was confirmed by monitoring the pH of the effluent. The carbon material was dried and ground to a fine (10 micrometer) powder.

[0077]An SEM micrograph of the carbon material is shown in FIG. 4. In contrast to the comparative PICA carbon of example 4, this inventive carbon comprises flakes of carbon material. It is believed that this structure facilitates packing of the carbon material during electrode fabrication.

[0078]A button cell was assembled according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| voltages | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com