Preparation method of high-activity molybdenum sulfide hydrogenation catalyst

A technology of hydrogenation catalyst and molybdenum sulfide, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problems of no catalyst hydrogenation active site, low size accumulation degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

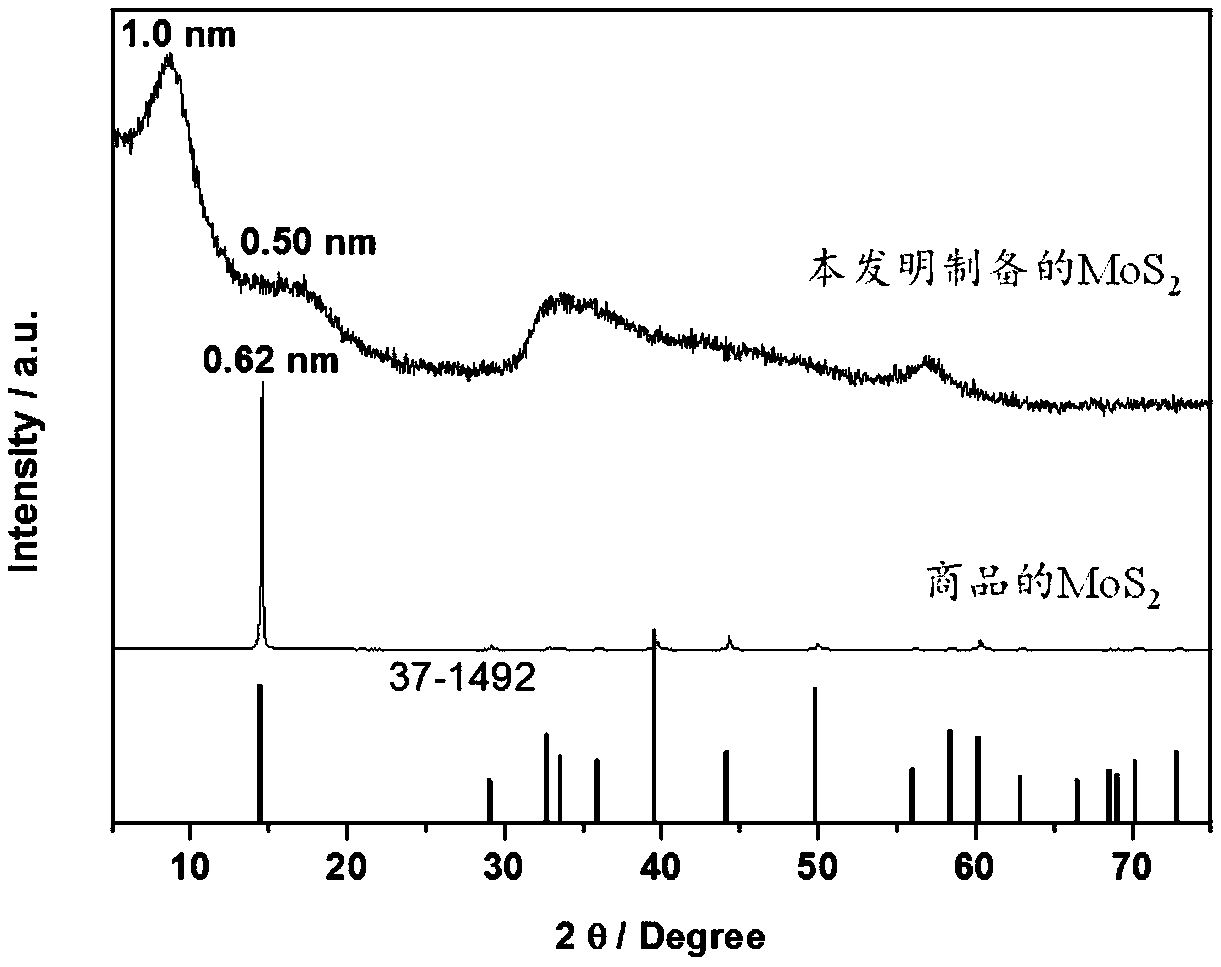

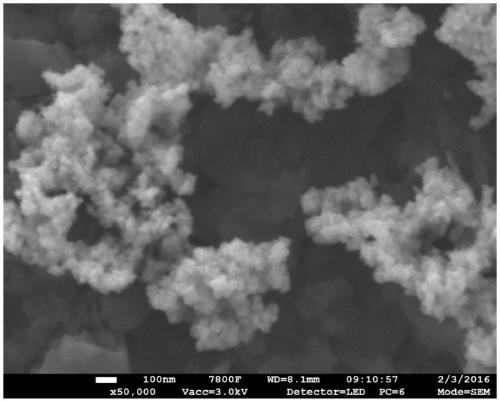

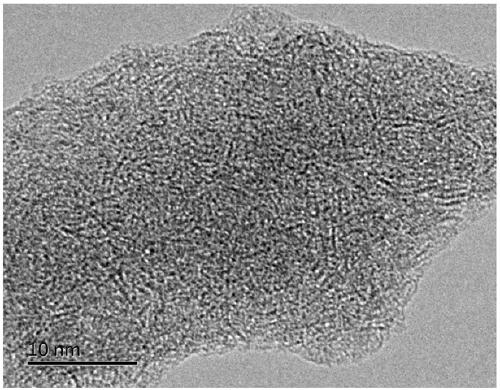

[0028] Disperse 1.0g of ammonium heptamolybdate and 2.3159g of L-cysteine in 60ml of glycerol, heat in a water bath to 60°C, stir to form a solution, and the S / Mo ratio is 3:1. After continuing to fully stir for 30 minutes, transfer the solution to a 100ml hydrothermal kettle, react at 180°C for 24 hours, naturally cool to room temperature, filter with suction, wash the product with deionized water and absolute ethanol, dry it under vacuum at 70°C overnight, and collect MoS 2 sample. As a comparison, the commercial MoS 2 Characterization and activity evaluation were performed. The two samples were characterized by XRD and HRTEM, and it was found that the two product components were MoS 2 (See figure 1 ), but unlike commodity MoS 2 The bulk multilayer stacked structure, the MoS prepared by the present invention 2 With enlarged interlayer, lower packing degree and smaller sheet size (see figure 2 and image 3 ). The two are used in the hydrogenation reaction of model...

Embodiment 2

[0030] Disperse 1.0g of ammonium heptamolybdate and 3.9166g of glutathione in 60ml of diethylene glycol, heat in a water bath to 60°C, stir to form a solution, and the S / Mo ratio is 2:1. After continuing to fully stir for 30 minutes, transfer the solution to a 100ml hydrothermal kettle, react at 140°C for 36 hours, naturally cool to room temperature, filter with suction, wash the product with deionized water and absolute ethanol, and dry it under vacuum at 70°C overnight to collect MoS 2 sample.

Embodiment 3

[0032] Disperse 0.8700g of phosphomolybdic acid and 9.5747g of thioacetamide in 60ml of a 10% mass ratio of water and glycerol mixed solution, stir to form a solution, and the S / Mo ratio is 20:1. After continuing to fully stir for 30 minutes, transfer the solution to a 100ml hydrothermal kettle, react at 220°C for 6 hours, naturally cool to room temperature, filter with suction, wash the product with deionized water and absolute ethanol, dry it under vacuum at 70°C overnight, and collect MoS 2 sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com